21

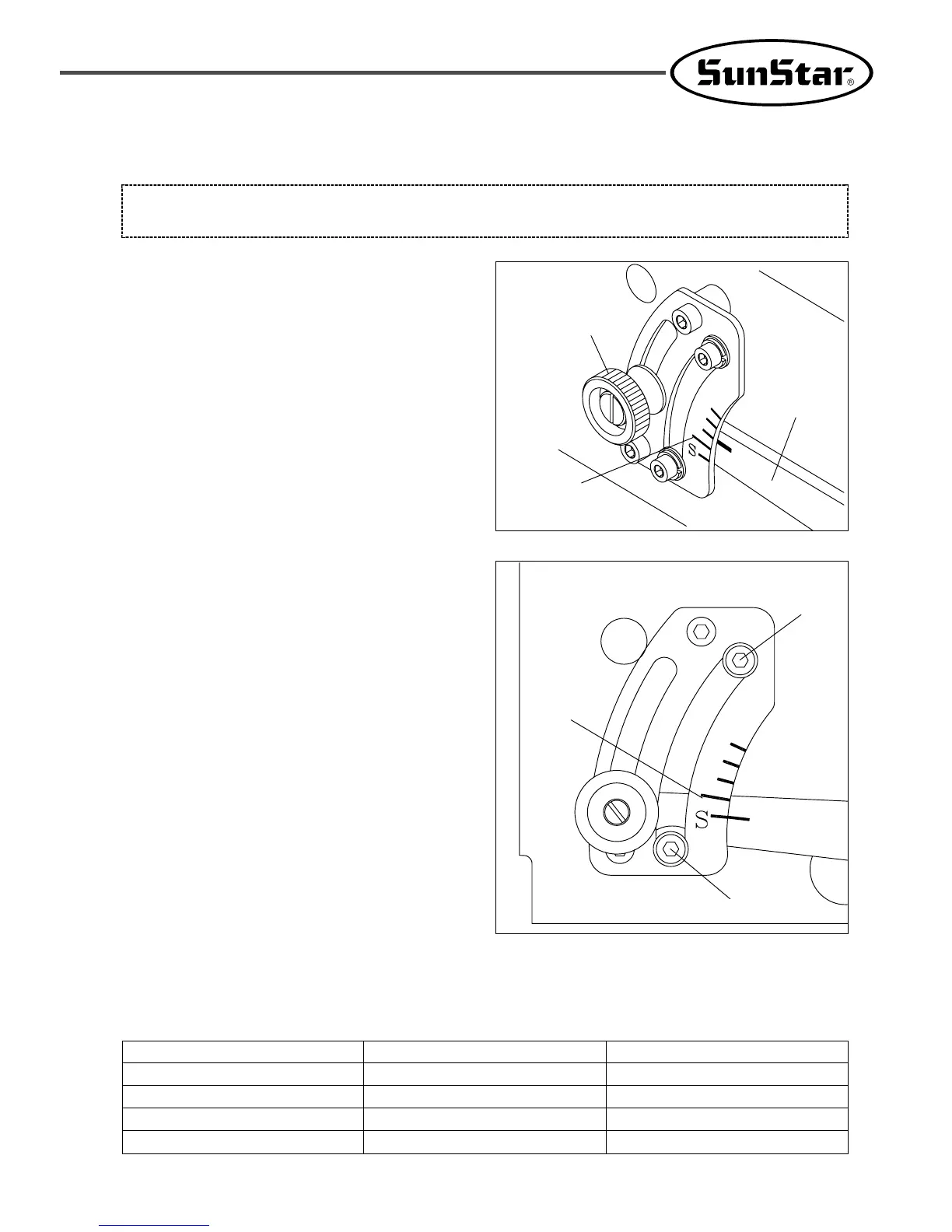

Stitch Length (mm) Max. Normal Differential Ratio Max. Reverse Differential Ratio

3.6 1 : 1.1 1 : 0.7

2.5 1 : 1.6 1 : 0.7

2.0 1 : 1.8 1 : 0.7

1.4 1 : 2 1 : 0.7

8) Adjustment of differential feed

[ Warning ]

Be sure to turn the power switch off before adjusting differential feed.

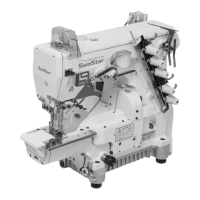

[ Figure 25 ]

①

②

③

③

④

④

(1) Normal Differential Feed (Shrink Sewing)

Loosen [the differential lever adjusting nut①]. Move

[the differential feed lever②] up or down to place it at

the desired position, and fasten [the nut①].

When the lever is set at [Graduation (Long) (C)], the

ratio of main feed to differential feed becomes 1:1.

When [the lever②] is set at the position higher than

Graduation C, the lever is in the normal differential feed

mode. The graduations located above Graduation C refer

to 1:1.25, 1:1.15, 1:1.75 and 1:2 from the bottom.

[ Figure 26 ]

(2) Reverse Differential Feed (Stretch Sewing)

When [the differential feed lever②] is set at the place

below [Graduation (Long)③], it is in the reverse

differential feed mode. When the lever is set at

[Graduation S], the ratio of main feed to differential feed

becomes 1:0.7.

(3) Adjustment of Differential Feed During Operation

When differential ratio needs to be adjusted during sewing, connect the lever to the chain.

To adjust the maximum or minimum limits of the differential feed lever, use [the differential feed lever stoppers (2EA)④].

※ Depending on the stitch length, the scope of differential ratios is different. Please see the table below

Loading...

Loading...