37

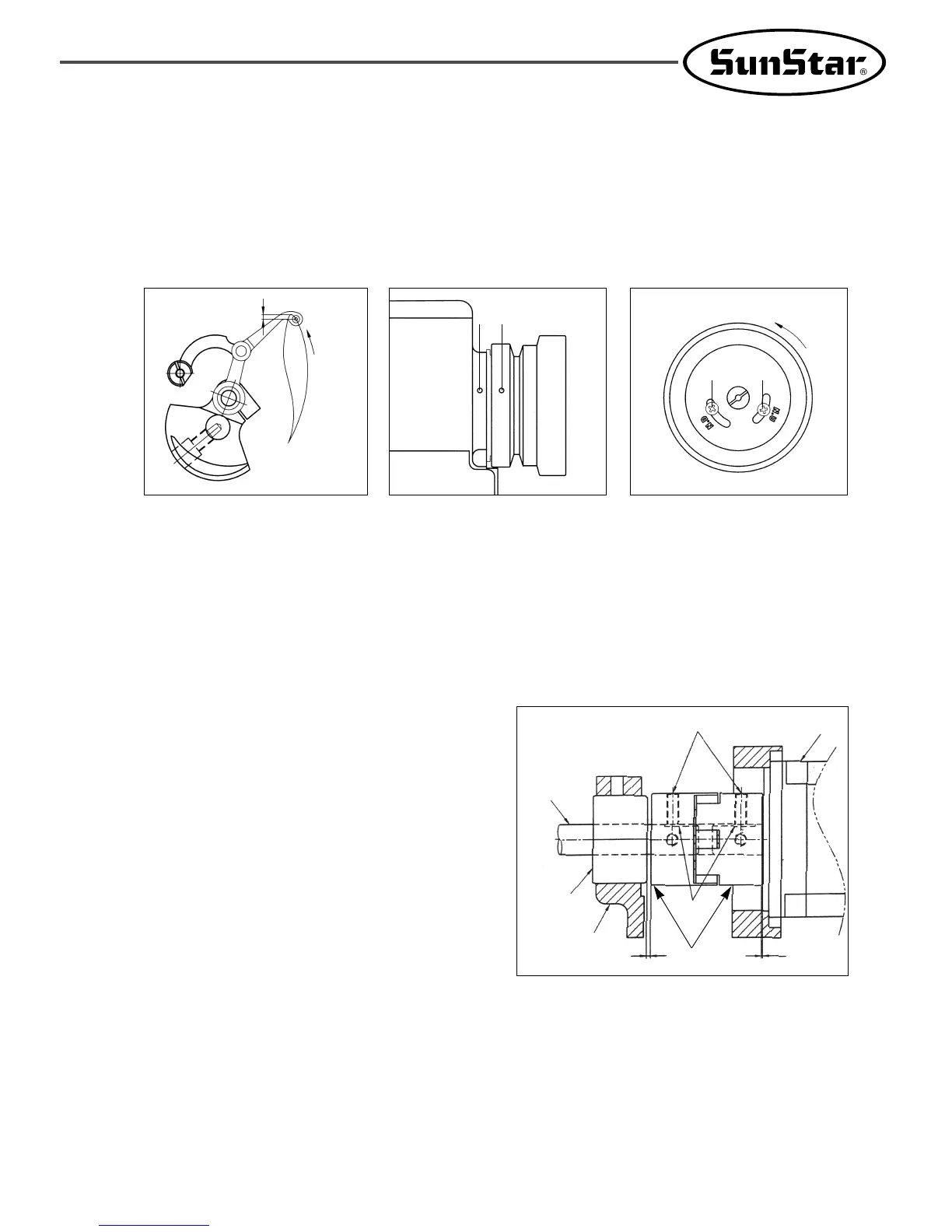

16) Mounting the Direct Motor and Adjusting

Method(B Series)

A. When you mount the coupling on the servo motor, fit the

screw No.1 of coupling to the flat surface of the servo

motor shaft and make the clearance between the

coupling and servo motor 0.7mm.

B. When you mount the coupling on the upper shaft, fit the

screw No.1 of coupling to the flat surface of the upper

shaft and make the clearance between the coupling and

upper shaft bushing(R) 2mm.

C. After mounting both couplings, check the positions of

each screws to the aligned.

※ If the positions of each screws are not aligned, the needle

does not stop normal position.

[ Fig. 57 ]

2

0.7

Upper

Shaft

Rear

Bushing

Upper Shaft

Coupling

Flat

Surface

ARM

Screw NO.1

Servo Motor

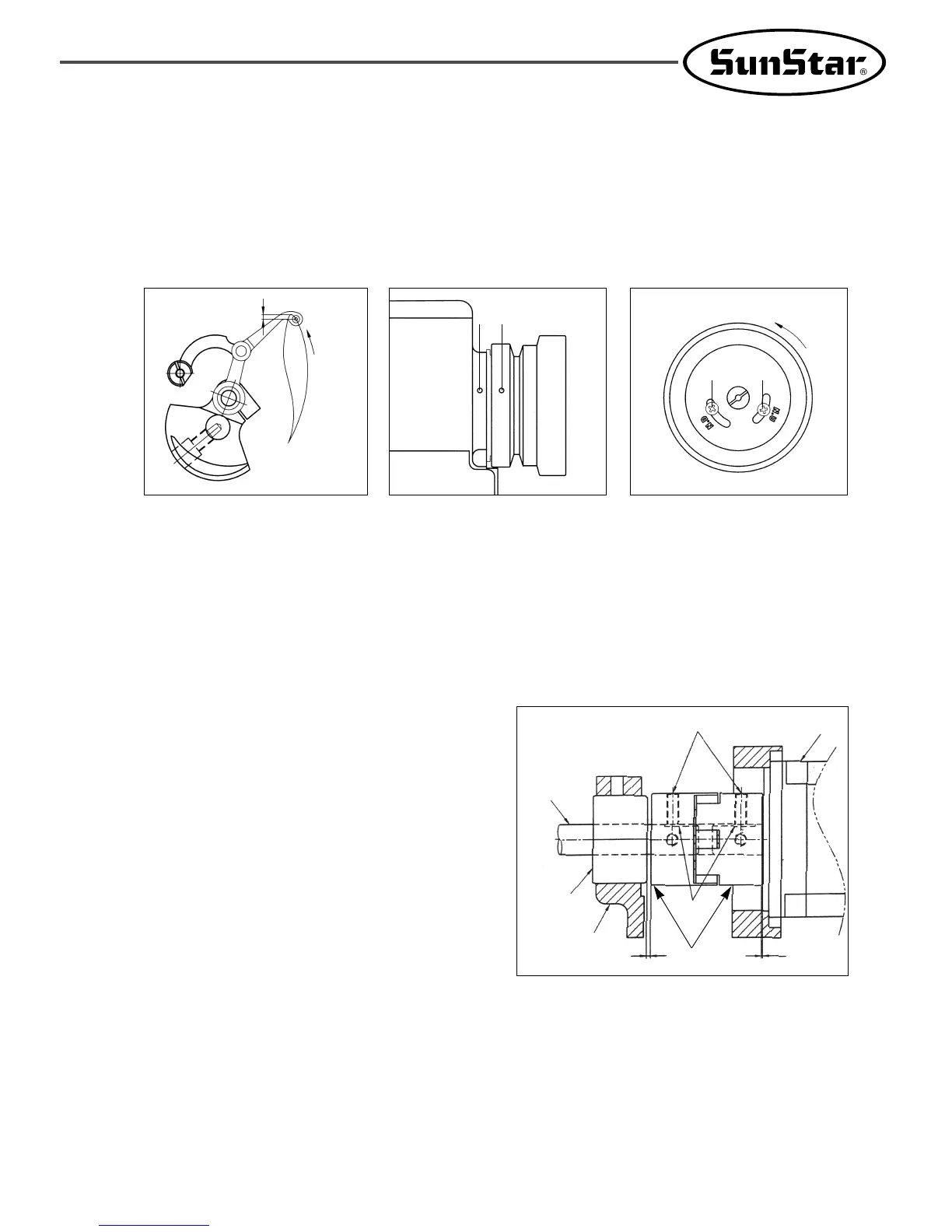

B. Adjusting the position of position detector

ⓐ Adjust the position of take-up lever to be same as Fig. 62 by turning the pulley. At this time, the white carving

sign of pulley should be straight line with the carving sign of arm.

ⓑ Unfasten the screw ① on the N.U carving sign of pulley to be located on the center of space, and fasten the

screw again.

ⓒ Unfasten the screw ② on the N.D carving sign and move to the right and left, then let it suspend on the place

where the needle bar just start ascending from the bottom.

[ Fig. 55 ]

[ Fig. 54 ]

Direction of

Rotation

About 3mm

[ Fig. 56 ]

Direction of

Rotation

①②

Loading...

Loading...