50

5) Adjusting the Speed for Ascension and Descent of Upper Feed Plate

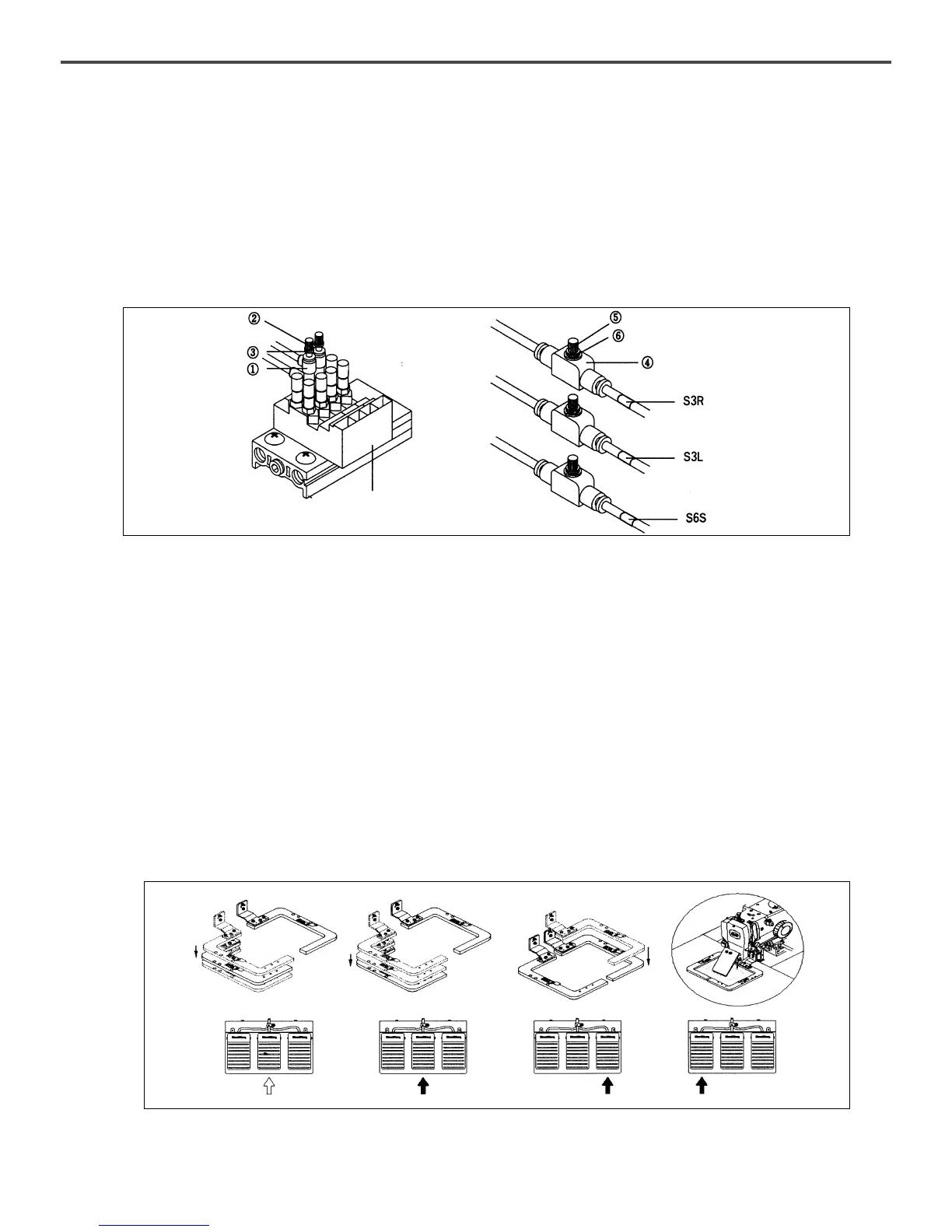

A. Like the fig. ⓐ, it you turn a handle ② on reducing valve ① solenoid valve attached to the bottom of table

clockwisse, the ascending speed of upper feed plate and support pressure during ascending will be inreased, if you

turn it counterclockwise, they are reduced, so that you should adjust it to be proper speed and fix them with fixing

nut ③(1.0~1.5kgf/㎠).

B. Like the fig. ⓑ, you turn a handle ⑤ of speed controller ④ clockwise, the descending speed of upper feed plate will

be reduced, if you turn counterclockwise, the descending speed will be increaed.

After adjusting it to be proper speed, fix it with fixing nut ⑥.

[ Fig. 73 ]

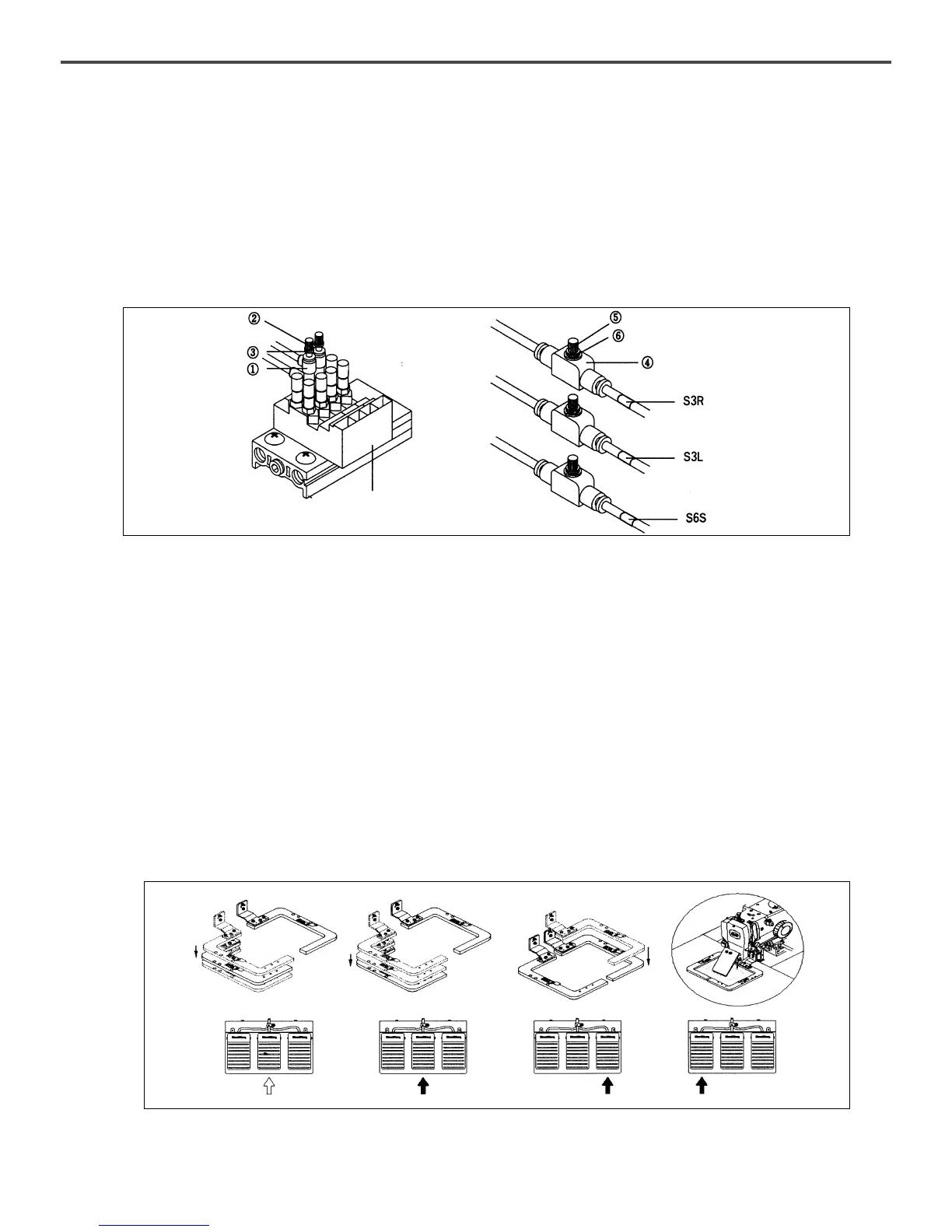

6) How to Use the Pedal Switch

A. Check the paramater, related to general sewing (function no.60), is set to “5”.

If not, please set the parameter to “5”(Refer to 7.29)Change of parameter related to general sewing).

B. Be familiar the basic direction and then adjust parameter to fit application for convenient use.

C. The pedal switch has three pedals, the right one ① moves the right upper feed plate, the intermediate one ② moves

the left upper feed plate and the left one ③ makes the sewing machine start.

D. Application(Standard type)

ⓐ The inter mediat pedal ② has two step switch, if you step on the first step, the left upper feed plate descends to

the intermediate position. (If you step off the pedal ②, the left upper feed plate ascends to the initial position).

ⓑ When the intermediate pedel ② is fully stepped, the left upper feed plate fully descends to the sewing material.

ⓒ When you step on the right pedal ①, the right upper feed plate descends to hold the sewing material.

(If you step on the right pldal ① again, the right upper feed plate ascends to the initial position)

ⓓ When both of the upper feed plates are descended, If you step on the left pedal ③, the machine starts.

[ Fig. 74 ]

③②① ③②① ③②①

③②①

Solenoid

[ ⓐ ]

[ ⓑ ]

Loading...

Loading...