32

Chapter 6: Resistance Welding Basics

Overview

SINGLE AND DUAL PULSE DESCRIPTION

Single pulse welds are typically used where the work pieces are fairly clean. Single pulse welds are

often beneficial when welding small parts such as fine wires where very low heat is required. Dual

pulse welds are helpful when the piece is dirty, or has oxides/plating on it. e first pulse preheats

the part, and burns off any oxides, helping the second pulse to perform the weld accurately and

consistently.

WELD FORMATION

Spot welding relies on metal resistivity (resistance) to heat and fuse metal. A large current is

passed through the workpiece metal. Energy is dissipated due to metal resistance in the form

of heat which melts and fuses the weld materials. ere are two phases to the melting process.

e welder must overcome both the material contact resistance and the bulk resistance of the

material.

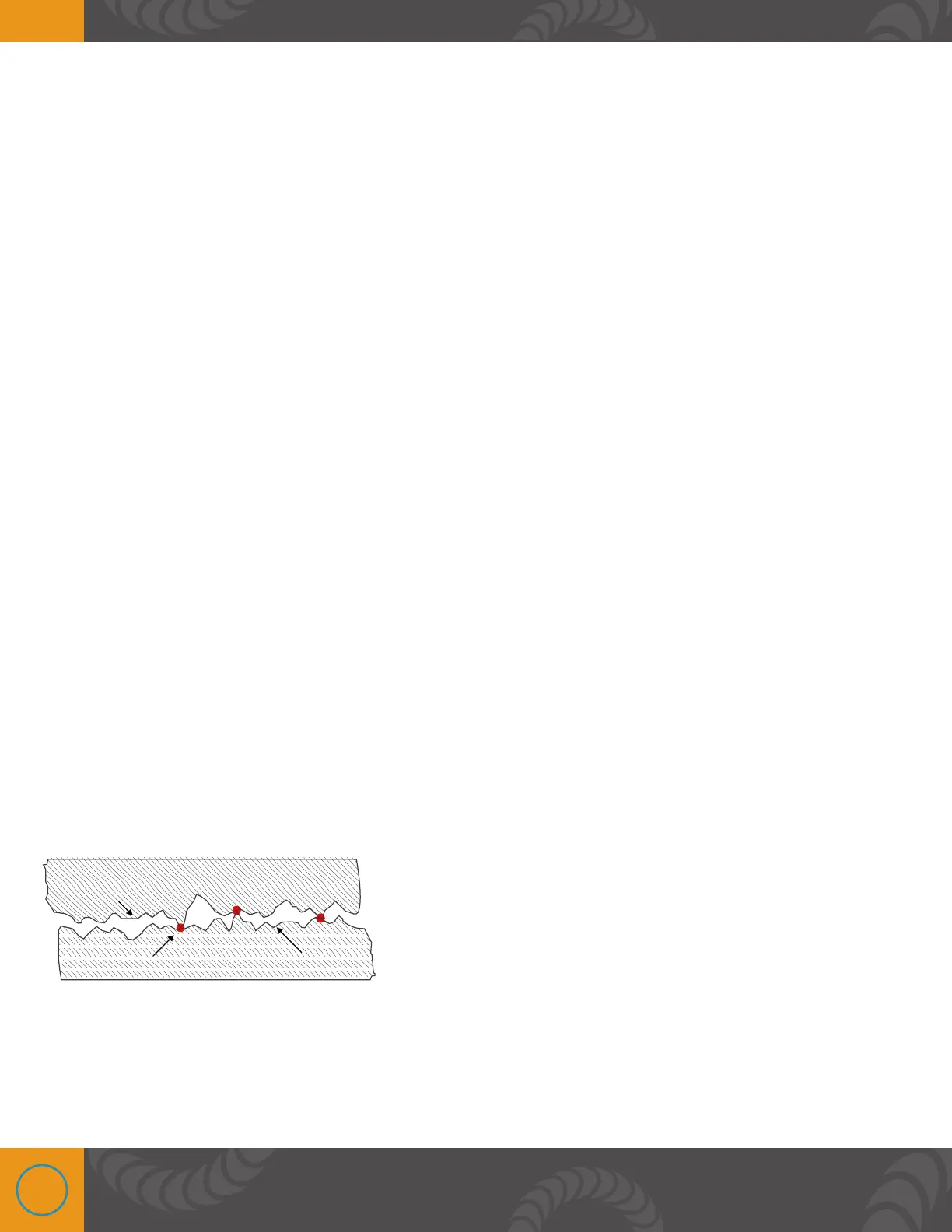

e figure below shows an example of a micro-scale surface profile. On the micro-scale, material

surfaces are rough and only contact in a limited number of locations. In the first few milliseconds

of weld formation, the high-resistance metal bridges melt, allowing other bridges to come

into contact to continue the melting process. When all of the bridges have fused, the contact

resistance is zero. e bulk resistance of the metal then plays the final role in the weld formation.

WELD PRESSURE

Several other factors play a part in the contact

resistance. e larger the contact resistance the

hotter the resultant weld. On the micro-scale, contact

resistance is reduced when more metal bridges or

contact points are formed. Using more electrode

pressure creates more metal bridges. is results in a lower contact resistance and a cooler weld.

Conversely, light electrode pressure results in less metal contact, higher resistance, and a hotter

weld. An appropriate amount of pressure should be used to insure good weld strength.

Surface 1

Contact Point

Surface 2

Loading...

Loading...