Overhaul Manual

O-360 and IO-360 Series Engines

PRESERVATION AND STORAGE

General

There is no practical procedure that will ensure

corrosion prevention on installed aircraft

engines. Geographical locations, season and

usage all influence the degree of corrosion. The

owner/operator is responsible for recognizing

the conditions that are conducive to corrosion

and for taking appropriate precautions.

Corrosion can occur in engines that are flown

only occasionally, regardless of geographical

location. In coastal areas and areas of high

humidity, corrosion can occur in as little as a few

days. The best method for reducing the likely

hood of corrosion is to fly the aircraft at least

once every week for a minimum of one hour.

NOTE:

Corrosion may reduce engine service

life. Primary wear concerns are

cylinders, piston rings, camshaft and

lifters.

WARNING

: HOT OIL MAY CAUSE BURNS TO

EYES AND SKIN. PUT ON SPLASH

GOGGLES AND INSULATED GLOVES, AND

OTHER PROTECTIVE GEAR. IN CASE OF

EYE CONTACT, FLUSH WITH WATER FOR

15 MINUTES AND SEEK MEDICAL

ATTENTION. IN CASE OF SKIN CONTACT,

WASH WITH SOAP AND WATER.

WARNING

: ENGINE OIL IS HAZARDOUS

AND MAY CAUSE INJURY TO SKIN AND

EYES. PUT ON PERSONNEL PROTECTIVE

GEAR.

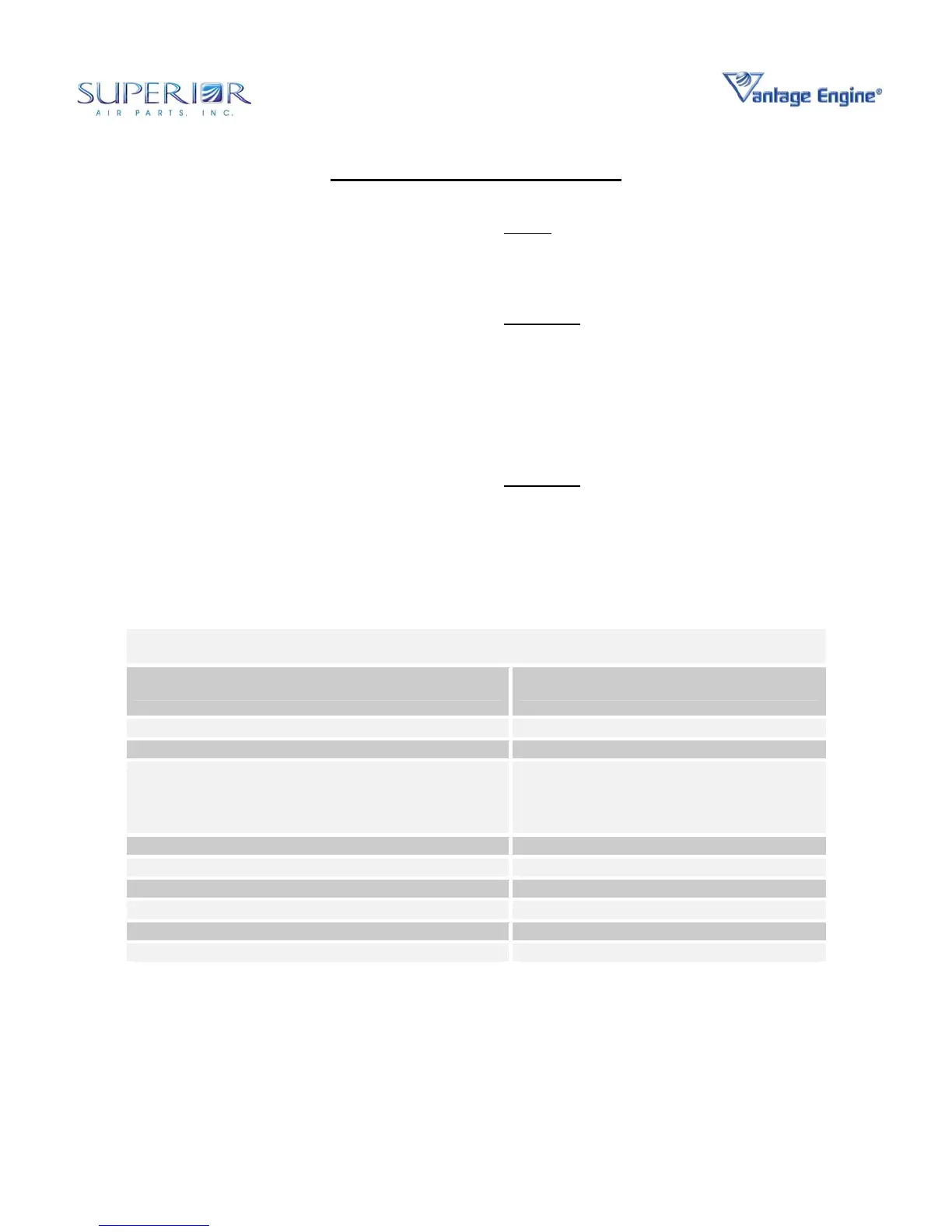

Table 72-00-12.1 • Storage Materials

NOMENCLATURE VENDOR

Preservative Oil MIL-C-6529 Type II, or equivalent Commercially Available

Preservative Oil MIL-L-46002, Grade 1, or equivalent Commercially Available

Cortec VpCI-326 Preservative Oil Concentrate, or

equivalent

Cortec Corp.

4119 White Bear Pkwy

St. Paul, MN 55510

612-429-1100

Preservative Oil Mil-C-16173 Grade 2, or equivalent Commercially Available

Dehydrator plugs, AN4062-1 or MS27215-2 Commercially Available

Covers, as required Commercially Available

Moisture Resistant Caps Commercially Available

Moisture Resistant Tape Commercially Available

1

© March 2005 Superior Air Parts Inc.

72-00-12

Preservation and Storage

Loading...

Loading...