Overhaul Manual

O-360 and IO-360 Series Engines

INSPECTION AND CHECK

General

The inspection of engine parts consists of three

(3) categories: visual, structural, and

dimensional. Visual and structural inspections

deal primarily with structural defects. The

dimensional checks are concerned with the size,

shape, and fit of a given part. Upon successful

completion of inspection, coat all steel parts with

preservative oil.

Visual inspections should precede all other

inspections. No cleaning operation should be

permitted until a complete initial visual

inspection is made of the part in question.

Residue from the engine’s operation can provide

additional information as to hidden defects or

other dangerous conditions. Refer to the

Cleaning section of this manual.

Structural inspections will include checking

flatness, out-of-roundness, and passageway

clearance. They may also include magnetic

particle and dye penetrant procedures as well as

eddy-current, ultra-sonic, or other non-

destructive testing methods.

For dimensional inspections, refer to the tables

set forth in the Fits and Clearances section of

this manual.

For repairs required prior to a final inspection or

dimensional check of a part, refer to the Repairs

section of this manual.

The use of a recording form is recommended

during the inspection procedures. The form

should be prepared so that all inspection and

subsequent repair and reassembly procedures

can be noted as they are completed. This

usage will also help prevent the omission of

components during the inspections and will

provide a place to record findings and comments

resulting from the inspections.

Materials and Tools

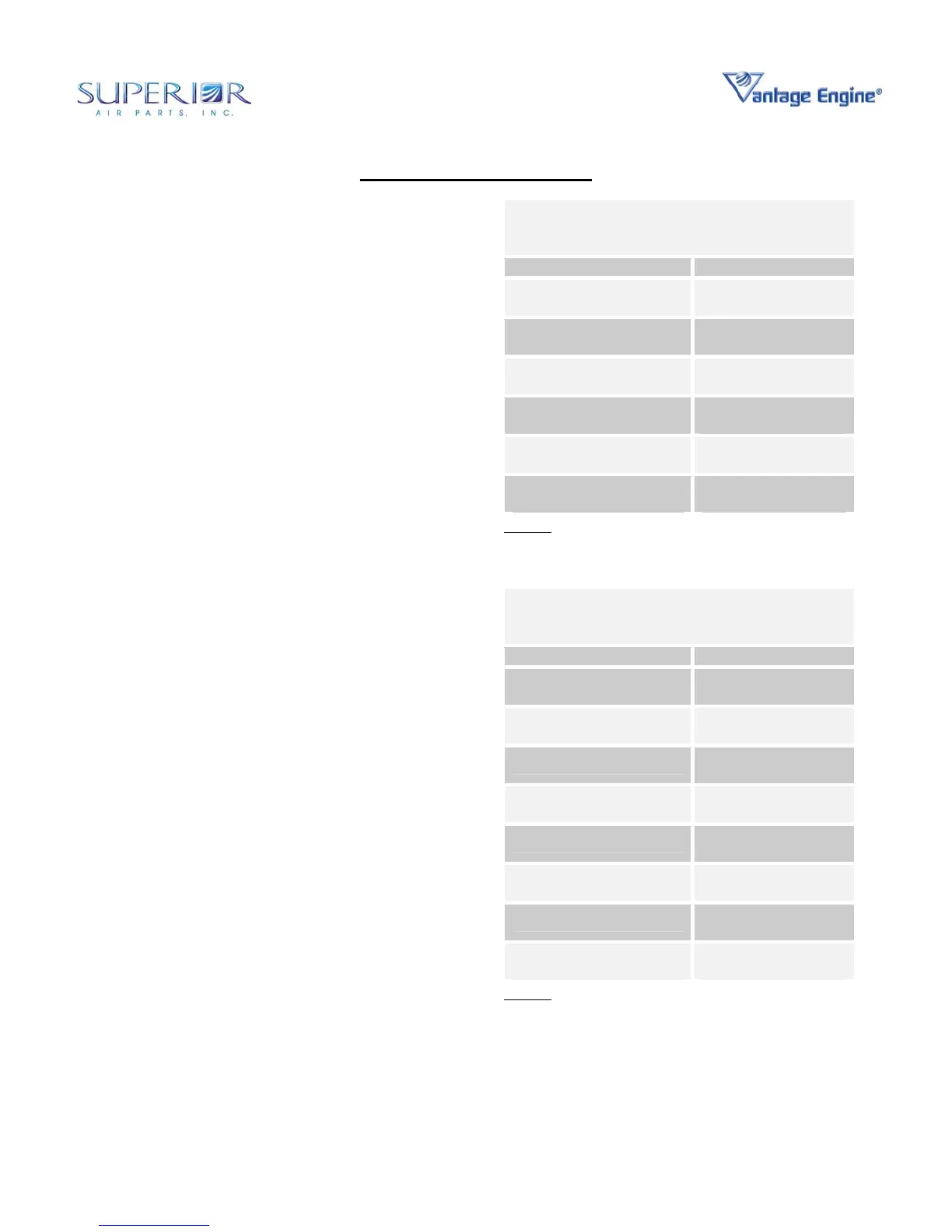

Materials required for inspection are listed Table

72-00-08.1. Special tools and equipment

required for inspection are listed Table 72-00-

08.2.

Table 72-00-08.1

Inspection Materials

Item Source

Magnetic base oil

Commercially

Available

Preservative oil

Commercially

Available

Dye penetrant and

developer

Commercially

Available

Acetone

Commercially

Available

Mineral Spirits

Commercially

Available

SAE #10 lubricating oil

(check fuel nozzle flow)

Commercially

Available

NOTE: Equivalent substitutes may be used.

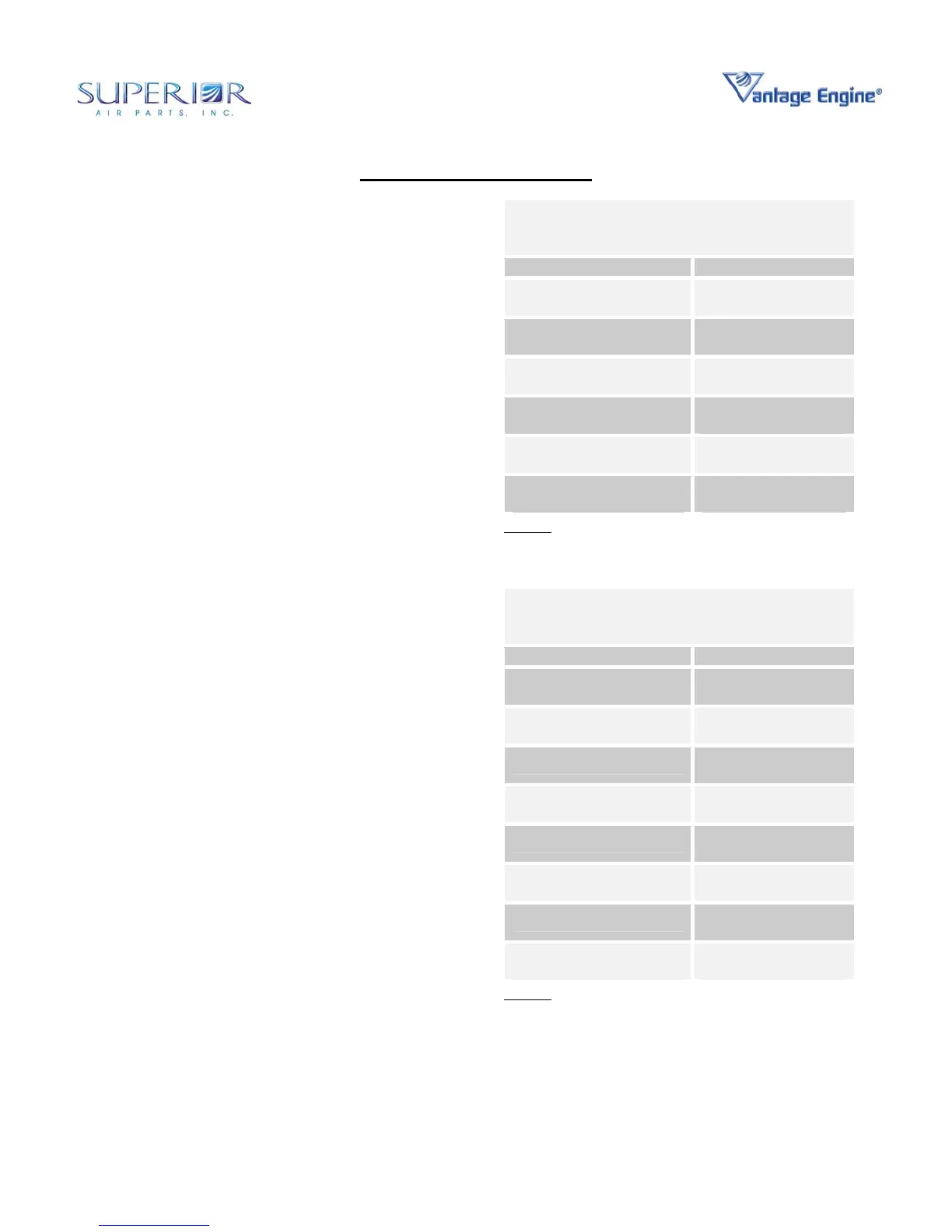

Table 72-00-08.2

Special Tools and Equipment

Item Source

Calipers and

micrometers: ID and OD

Commercially

Available

10X Magnifying Glass

Commercially

Available

Machinist’s Ruler

Commercially

Available

Small Flashlight

Commercially

Available

Vee Blocks

Commercially

Available

Dial Indicator

Commercially

Available

Spring Tension Tester

Commercially

Available

Magnetic Particle

Inspection Equipment

Commercially

Available

NOTE: Equivalent substitutes may be used.

1

© March 2005 Superior Air Parts Inc.

72-00-08

Inspection and Check

Loading...

Loading...