Overhaul Manual

O-360 and IO-360 Series Engines

11

© March 2005 Superior Air Parts Inc.

72-00-13

Repair Procedures

REPAIR NO. 4

PAINTED PARTS

Painted Parts Repair

Some parts may have had paint removed from

either normal operation or during the cleaning

and inspection procedures. The new crankcase

and other aluminum cast components have

been alodined after machining and prior to any

hardware installation per MIL-C-5541, Class 1A.

Parts requiring the use of paint for protection

should be painted in accordance with the

following recommendations using material from

the list of approved materials. See Table 72-00-

15.6.

All paint used in these procedures should be

sprayed on. If it is necessary to brush the paint

on, extreme care must be exercised to prevent

excessive accumulation of paint in small corners

or void areas of the crankcase.

NOTE:

All machined bosses should be

masked before painting. Do not paint

areas under hold-down nuts or bolt

heads where torque is required.

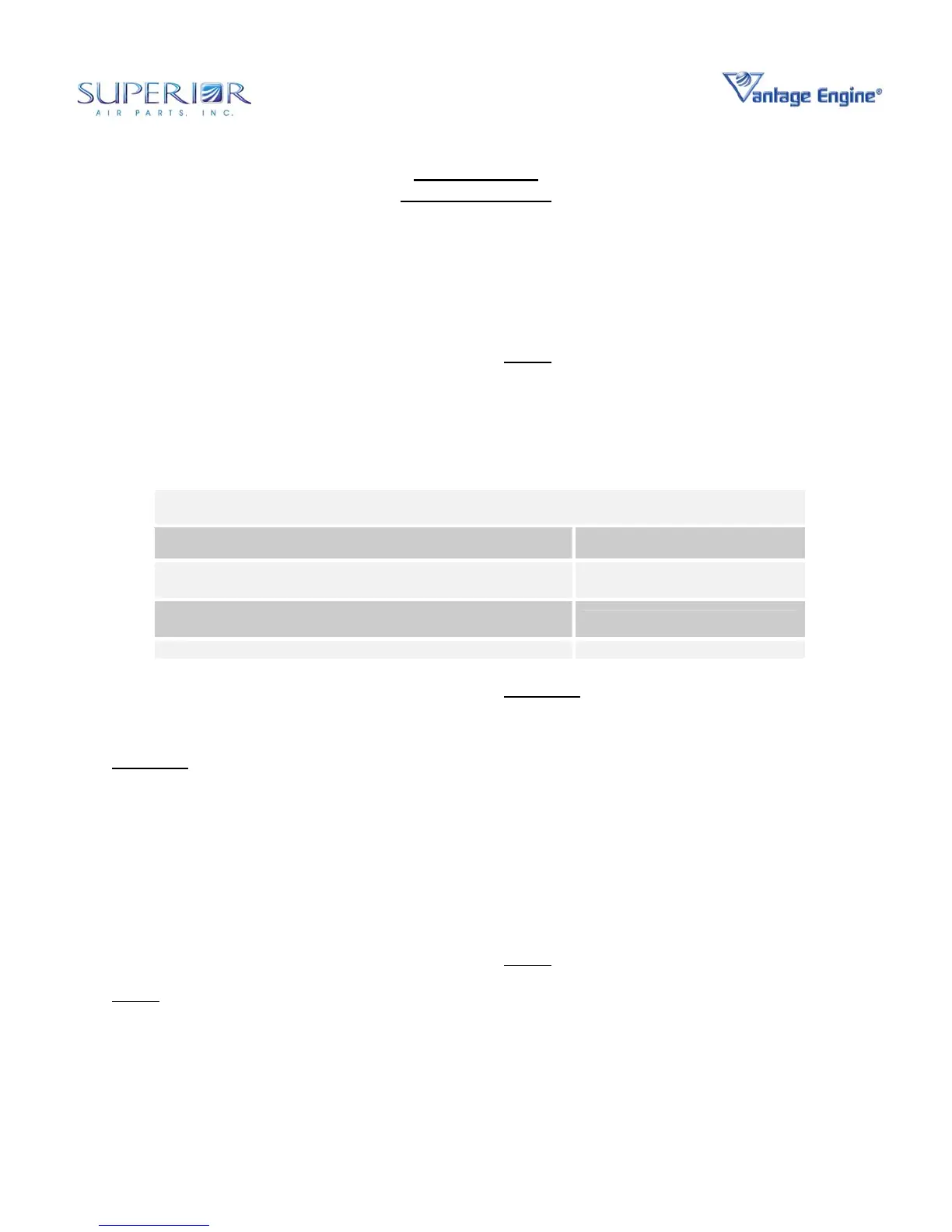

Table 72-00-15.6 • Consumable Materials for Paint Procedures

Material Source

Resin-type enamel, AMS 3125C or equivalent MIL-E-7729

(such as Randolph Black #303)

Commercially Available

Toluene or equivalent AMS3180 (or equivalent Federal

Spec. TT-T-548)

Commercially Available

Zinc chromate primer Commercially Available

A. Aluminum and steel parts

(1) Clean and degrease all parts prior to

paint procedures.

WARNING

: SOLVENT IS TOXIC. USE IN

WELL-VENTILATED AREA. PREVENT EYE

AND SKIN CONTACT AND DO NOT

BREATHE VAPORS. IN CASE OF EYE

CONTACT, FLUSH WITH WATER FOR 15

MINUTES AND SEEK MEDICAL ATTENTION.

IN CASE OF SKIN CONTACT, WASH WITH

SOAP AND WATER.

(2) Apply one coat zinc chromate primer,

thinned with approximately 2 parts

toluene, and allow to air dry.

NOTE:

Parts from which the paint has not

been removed may be repainted

without the primer coat.

(3) Apply one coat of enamel and bake at

250°F for ½ hour. If allowed to air dry,

an inferior finish will result.

WARNING

: USE THE CORRECT PERSONAL

PROTECTION. HEATED PARTS WILL

CAUSE BURNS.

B. Cylinder Barrels

(1) Thoroughly clean all old paint from the

cylinder. A vapor degreaser is well

suited for this purpose.

(2) Superior Air Parts does not recommend

painting of cylinder heads for optimum

cooling. Only alodine is required for

cylinder head surface protection.

(3) Mask off the cylinder head, plug flange

bolt holes and cover cylinder bore.

NOTE:

Masking materials may include tape,

corks, plugs, foil, metal covers, etc.

(4) Spray a very light coat of zinc chromate

primer (0.0005 in. maximum thickness)

on the cylinder flange. A correct

thickness of paint will appear green with

a yellow tint and allow the metal to show

Loading...

Loading...