Overhaul Manual

O-360 and IO-360 Series Engines

ENGINE INSTALLATION

General

This section consists of installation procedures.

Equipment and Materials to accomplish

installation procedures are listed in Table

72-00-10.1.

•

• Model specific illustrations and data may be

found in the Model Specification Data

attached to the Installation and Operation

Manual (SVIOM01) for the appropriate

engine model.

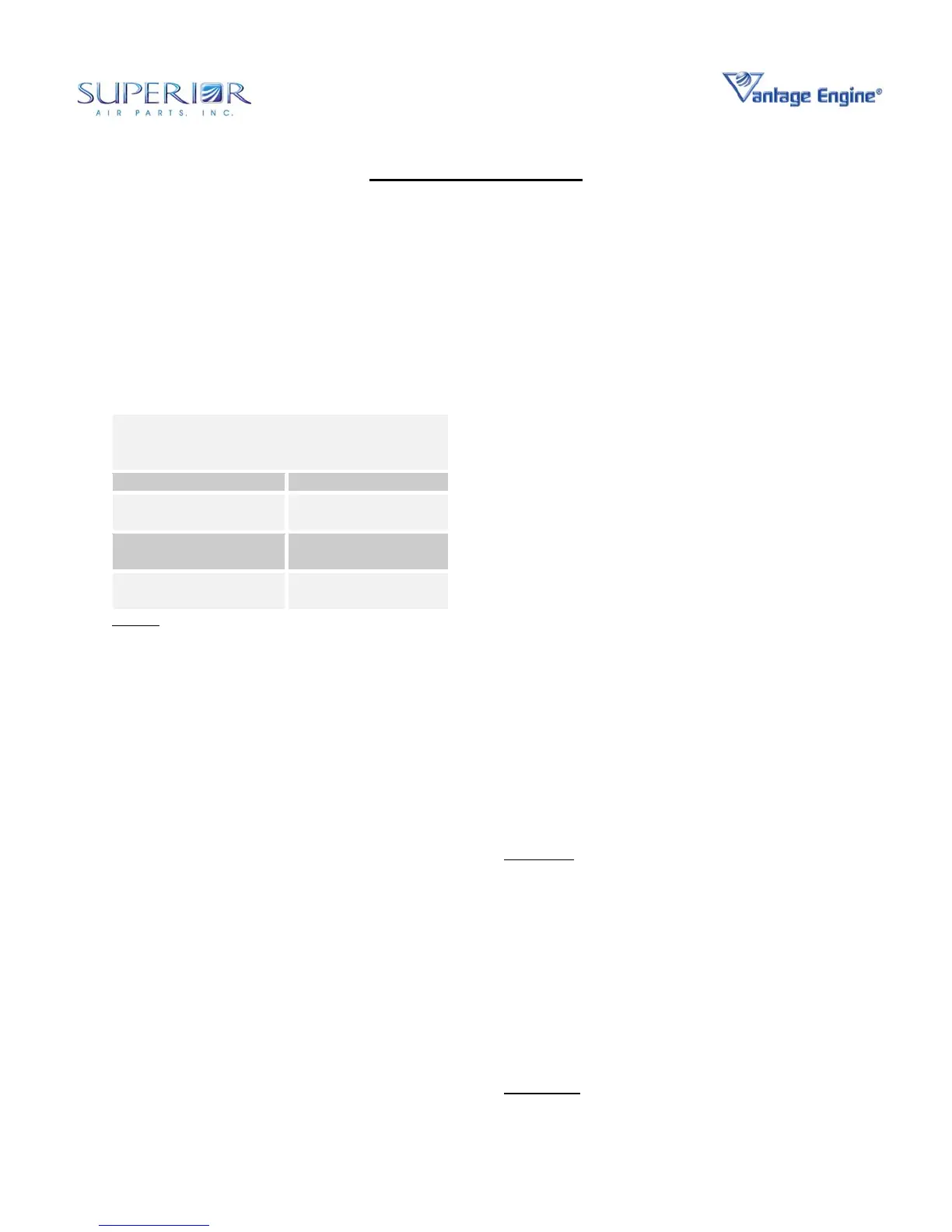

Table 72-00-10.1 • Equipment and

Materials List

Item Vendor

Engine Hoist

Commercially

Available

Aircraft engine oil

Commercially

Available

Accessory drive pad

gaskets as required

Commercially

Available

NOTE: Standard aviation shop tools are

required.

Preparing Engine for Service

•

•

•

•

•

•

•

•

•

•

If the engine has been preserved, perform

the following steps:

1. Remove the shipping plugs installed in

the upper spark plug holes and inspect

the cylinder bores for rust or

contamination.

2. Remove the shipping plugs installed in

the lower spark plug holes and turn the

crankshaft through at least twice in

order to remove the cylinder

preservation oil from the cylinders.

3. Drain preservation oil from engine.

Engines that have been subjected to a cold

environment for long periods of time should

be placed into at least a 70°F atmosphere

for 24 hours or more before attempting to

drain the preservative oil. If this cannot be

done, heat the engine with heating lamps

before attempting to drain the engine.

Remove exhaust port protective plugs.

Service the lubrication system with mineral

(non-detergent) oil.

Remove the shipping plate from the

propeller governor pad as required for

governor installation. Lubricate the governor

shaft splines with engine oil, install a new

gasket and then install the propeller

governor control.

Align the spline of the governor drive gear

and be sure that the governor is fully seated

to the adapter prior to installing the attaching

hardware. This eliminates the possibility of

misalignment.

Attach with plain washers and new lock

washer. Torque the nuts to 200 in-lb.

Optional accessories such as vacuum

pumps, hydraulic pumps, etc., may be

installed on the accessory drive pads

located on the rear of the accessory

housing. Remove the accessory drive

covers and install new gaskets. Install

accessories in accordance with the

manufacturer's instructions.

Install any airframe manufacturers' required

cooling baffles, hoses, fittings, brackets and

ground straps in accordance with airframe

manufacturer's instructions.

Installation of Engine

Install engine per airframe manufacturer's

instructions. Use only the lifting eye bracket

installed on the backbone of the crankcase

to hoist the engine.

Consult airframe manufacturer's instructions

for engine to airframe connections. Remove

all protective covers, plugs, caps and

identification tags as each item is connected

or installed.

CAUTION

: FAILURE TO PURGE THE

AIRCRAFT FUEL TANKS AND LINES CAN

CAUSE ERRATIC FUEL SYSTEM OPERATION

AND DAMAGE TO ITS COMPONENTS.

The aircraft fuel tanks and lines must be

purged to remove all contamination prior to

installation in the main fuel inlet line to the

fuel pump or engine.

•

• Install the approved propeller in accordance

with the manufacturer's instructions.

WARNING

: DO NOT INSTALL THE IGNITION

HARNESS "B" NUTS ON THE SPARK PLUGS

1

© March 2005 Superior Air Parts Inc.

72-00-10

Engine Installation

Loading...

Loading...