Overhaul Manual

O-360 and IO-360 Series Engines

CLEANING

General

Cleanliness of the aircraft engine is crucial to its

optimum performance. This section provides

information on materials, tools, and guidelines

for cleaning.

After the initial visual inspection of internal

engine parts, it is necessary to thoroughly clean

the engine components for detailed inspection.

Since this visual inspection is made during and

after disassembly, the components should be

cleaned afterwards and tagged to facilitate

further non-destructive inspection methods.

This identification procedure will also help

prevent these components from being

overlooked.

It is important to remember to visually inspect an

engine prior to cleaning. Residue from the

engine’s operation can provide information as to

hidden defects or other dangerous conditions.

Tools and Materials

For tools required during cleaning, refer to Table

72-00-07.1. For consumable materials required

during cleaning, refer to Table 72-00-07.2.

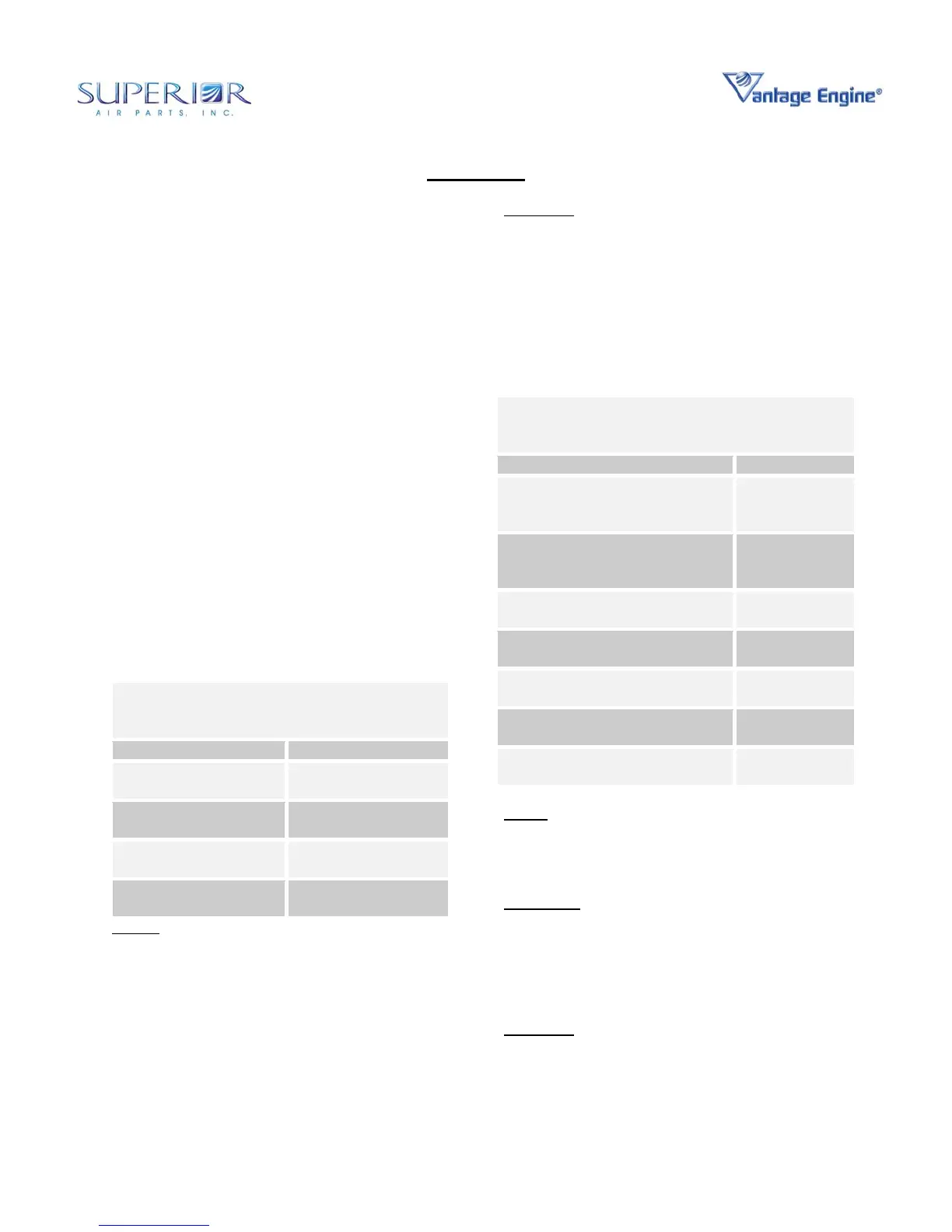

Table 72-00-07.1

Equipment Required for Cleaning

Item Vendor

Brush (soft and stiff

bristles)

Commercially

Available

Immersing tank

Commercially

Available

Scraper (wood)

Commercially

Available

Grit blaster

Commercially

Available

NOTE: Equivalent substitutes may be used.

Cleaning Instructions

Two (2) processes are used in cleaning engine

parts; degreasing to remove dirt and sludge (soft

carbon) and the removal of hard carbon by

decarbonizing, brushing or scraping and grit

blasting.

CAUTION

: DO NOT USE SAND OR METALLIC

ABRASIVES WITH THE GRIT BLASTING

EQUIPMENT.

Degreasing

Degreasing is accomplished by immersing or

spraying the part in solution of white furnace oil

(38-40 specific gravity) or another suitable

solvent such as Varsol or Perm-A-Chlor.

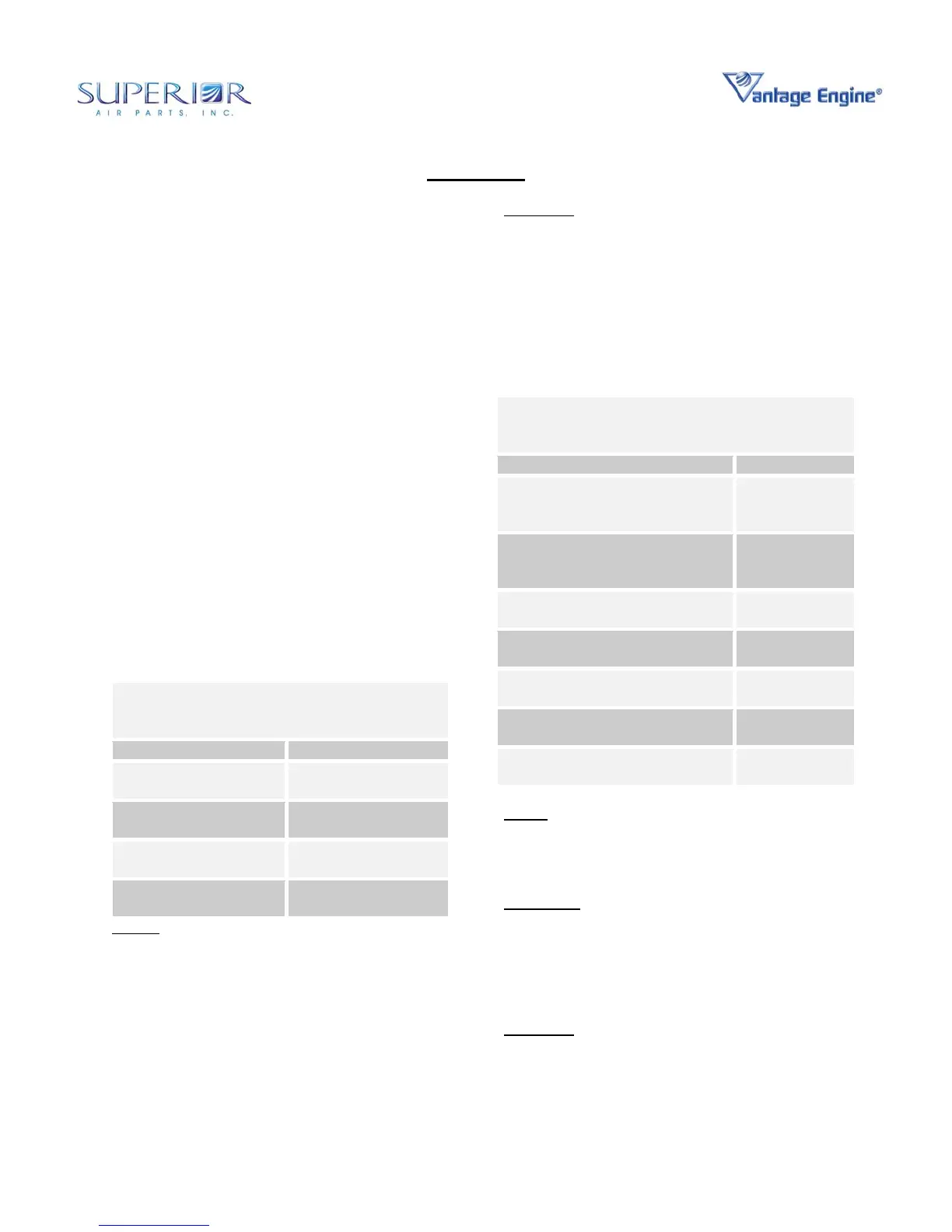

Table 72-00-07.2

Materials Required for Cleaning

Item Vendor

Cleaning solvent or degreaser

such as white furnace oil,

Varsol, or Perm-A-Chlor

Commercially

Available

Decarbonizing solutions such

as Gunk, Penetrol, Carbrax,

Super-Chemco, or Gerlach #70

Commercially

Available

Isopropyl Alcohol

Commercially

Available

Aerosol electrical contact

cleaner

Commercially

Available

Lubricating Oil (SAE 20)

Commercially

Available

Corrosion preservative oil

Commercially

Available

Abrasive cloth (crocus cloth)

Commercially

Available

NOTE

: Residue from the solvent washing must

be captured and contained to prevent

contamination of the surrounding

environment.

WARNING

: USE THE CORRECT PERSONAL

PROTECTION. SOME CHEMICAL

SOLUTIONS CAN CAUSE SKIN, EYE AND

LUNG DAMAGE. FOLLOW THE

MANUFACTURER'S INSTRUCTIONS FOR

EACH CLEANING SOLUTION.

CAUTION

: IF ANY WATER-MIXED

DEGREASING SOLUTIONS CONTAINING

CAUSTIC COMPOUNDS OR SOAP ARE

USED, EXTREME CARE MUST BE

EXERCISED. THESE COMPOUNDS IN

1

© March 2005 Superior Air Parts Inc.

72-00-07

Cleaning

Loading...

Loading...