Overhaul Manual

O-360 and IO-360 Series Engines

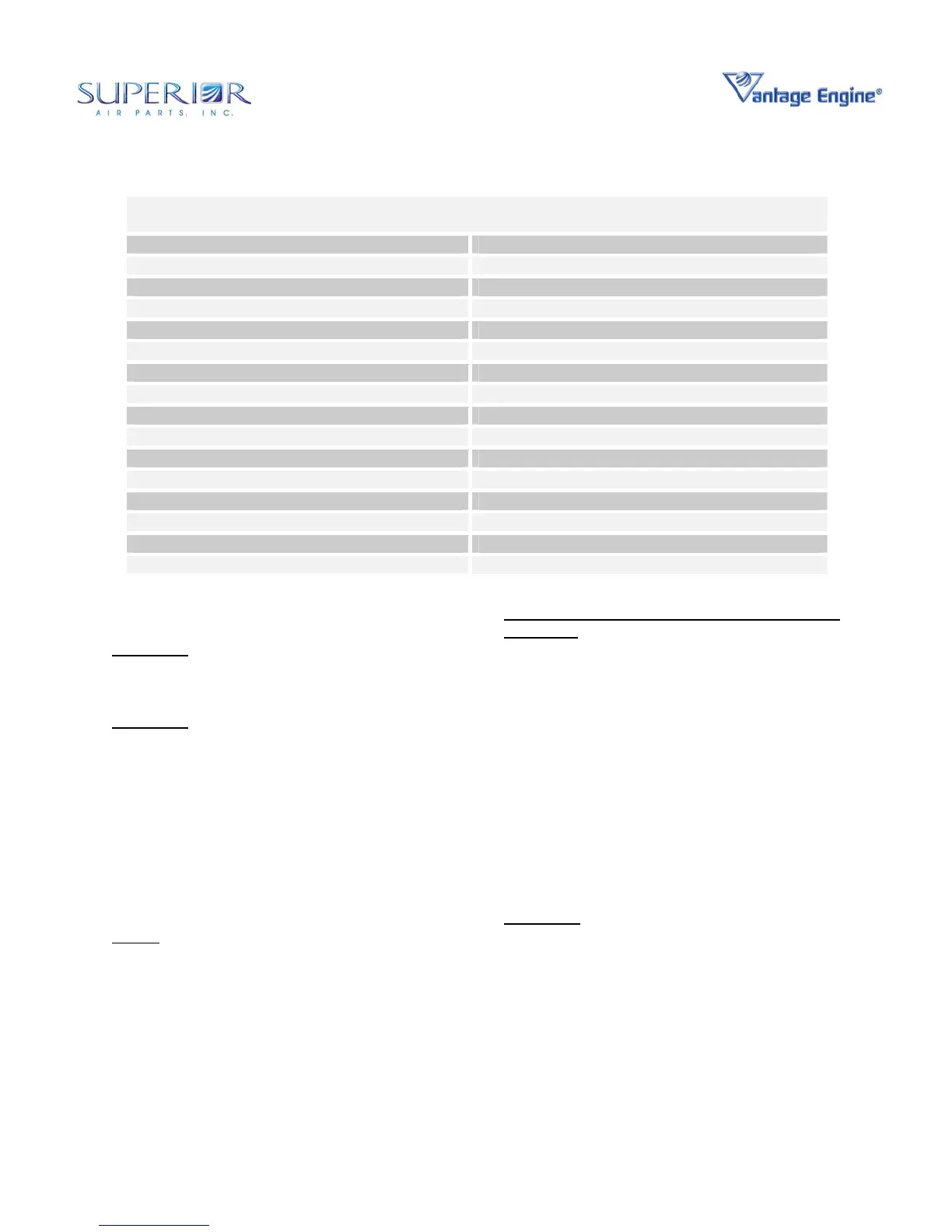

Table 72-00-09. 2 • Special Tools and Equipment

Description Source

Compressor, Valve Spring & Bar Commercially Available

Piston Ring Expander Commercially Available

Puller Set, Oil Seal Commercially Available

Puller, Slide Hammer – Medium Commercially Available

Puller, Valve Guide Commercially Available

Socket, Connecting Rod Nut Commercially Available

Stand, Engine Commercially Available

Tool, Crankcase Separating Commercially Available

Tool, Intercylinder Baffle Commercially Available

Cylinder Base Wrenches, 3/4” and 9/16” Commercially Available

Piston Ring Grinder Commercially Available

Piston Ring Compressor Commercially Available

Nose Seal Installation Tool Commercially Available

Snap Ring Pliers Commercially Available

Engine Assembly

WARNING

: PUT ON SAFETY GOGGLES

WHEN INSTALLING OR REMOVING SAFETY

WIRE.

WARNING

: LUBRICANTS ARE TOXIC AND

FLAMMABLE. DO NOT BREATHE VAPORS.

BEFORE YOU USE, READ THE MATERIAL

SAFETY DATA SHEET (MSDS) FROM THE

MANUFACTURER OR SUPPLIER. USE IN A

WELL-VENTILATED AREA FREE FROM

SPARKS. WEAR PROTECTIVE GEAR. IN

CASE OF EYE CONTACT, FLUSH WITH

WATER FOR 15 MINUTES AND SEEK

MEDICAL ATTENTION. IN CASE OF SKIN

CONTACT, WASH WITH SOAP AND WATER.

NOTE:

Unless otherwise specified, all torque

loads listed for nuts, bolts, and screws

are for use with pre-lube oil.

Crankcase Inspection and Preparation for

Assembly.

(1) Place crankcase halves on workbench.

Check for handling damage. Inspect for

slight nicks and burrs surface finish, split

lines, bearing and cam bores, mating

surfaces, and tappet bores.

(2) Inspect studs for thread damage, bent

condition.

(3) Inspect tang slots for deformation.

Install center and aft main bearings in

case halves.

(4) Check front main bearing retention

dowel installation for correct height of

0.070-0.090 in. Refer to Figure 72-00-

09.1.

WARNING

: WHEN YOU USE COMPRESSED

AIR TO CLEAN OR DRY PARTS, MAKE SURE

THAT THE PRESSURE IS NOT MORE THAN

30 PSI. DO NOT DIRECT THE AIRSTREAM

AT PERSONNEL OR LIGHT OBJECTS. PUT

ON GOGGLES OR A FACE SHIELD TO

PROTECT YOUR EYES. IF YOU GET AN EYE

INJURY, GET MEDICAL ATTENTION.

(5) Inspect oil galleys in each crankcase

half to ensure they are clean and that

2

© March 2005 Superior Air Parts Inc.

72-00-09

Engine Assembly

Loading...

Loading...