the larger the gain will be in the same condition. The controller can identify the driving and

brake state according to the signals of weight conductor, and then work out desirable torque

compensation values.

When the system uses analog weighing, these group parameters are used for adjusting

starting. Details of adjusting ways are as follows:

When motor is in driving state, If the lift rolls back wh

en starts, increase F8-03; if the lift rushes

to start, reduce F8-03.

When motor is in brake state, if the lift rolls back when starts, increase F8-04; if the lift rushes

to start, reduce F8-04.

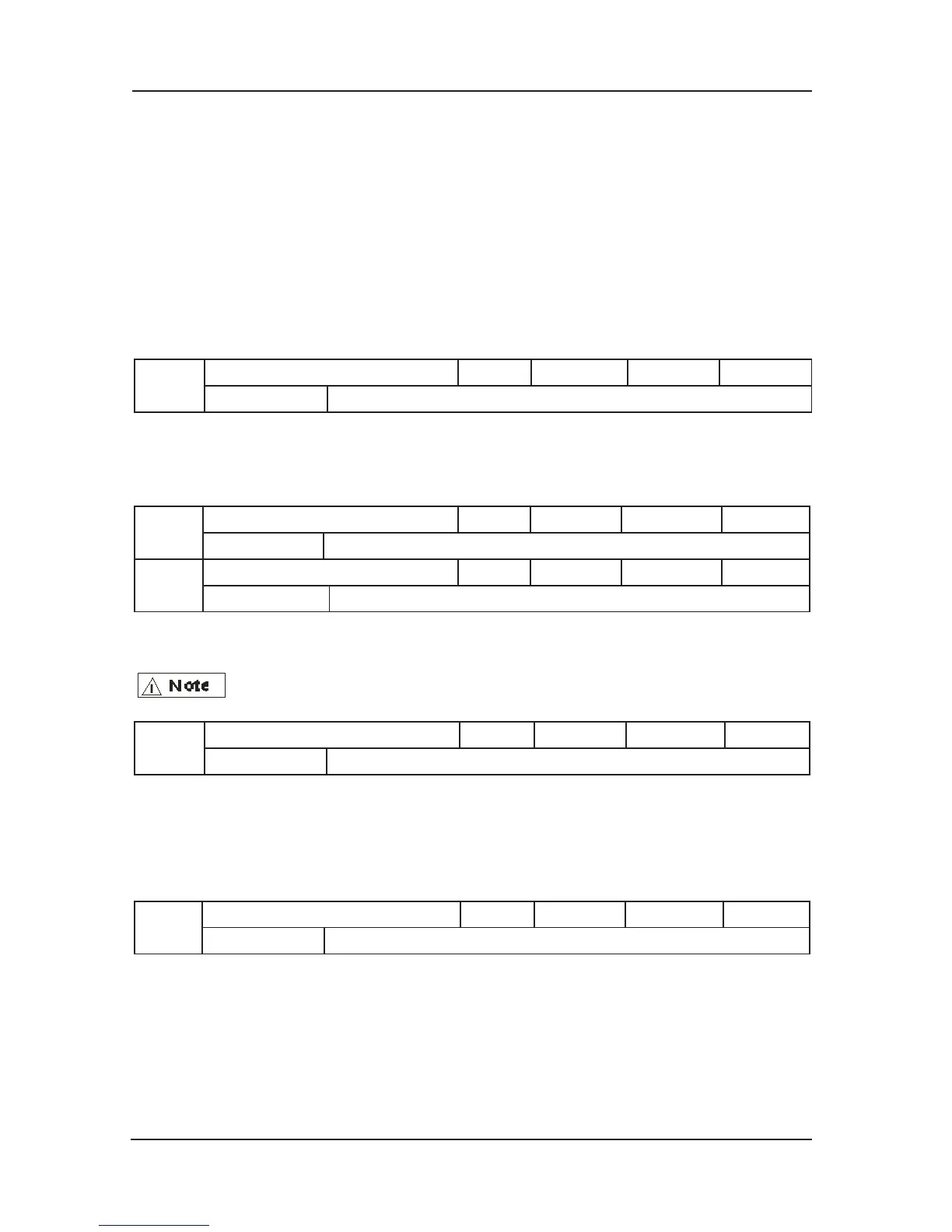

F8-05

Car load Default 0 Min. Unit 1

Setting Range 0~1023

F8-05 is the read only parameter, reflecting the load state in car. The parameter is the

NICE3000 sampling value of load. If F5-36 setting is less than 2, set F8-05=0.So F5-36 must

be set right when using preset torque compensation function.

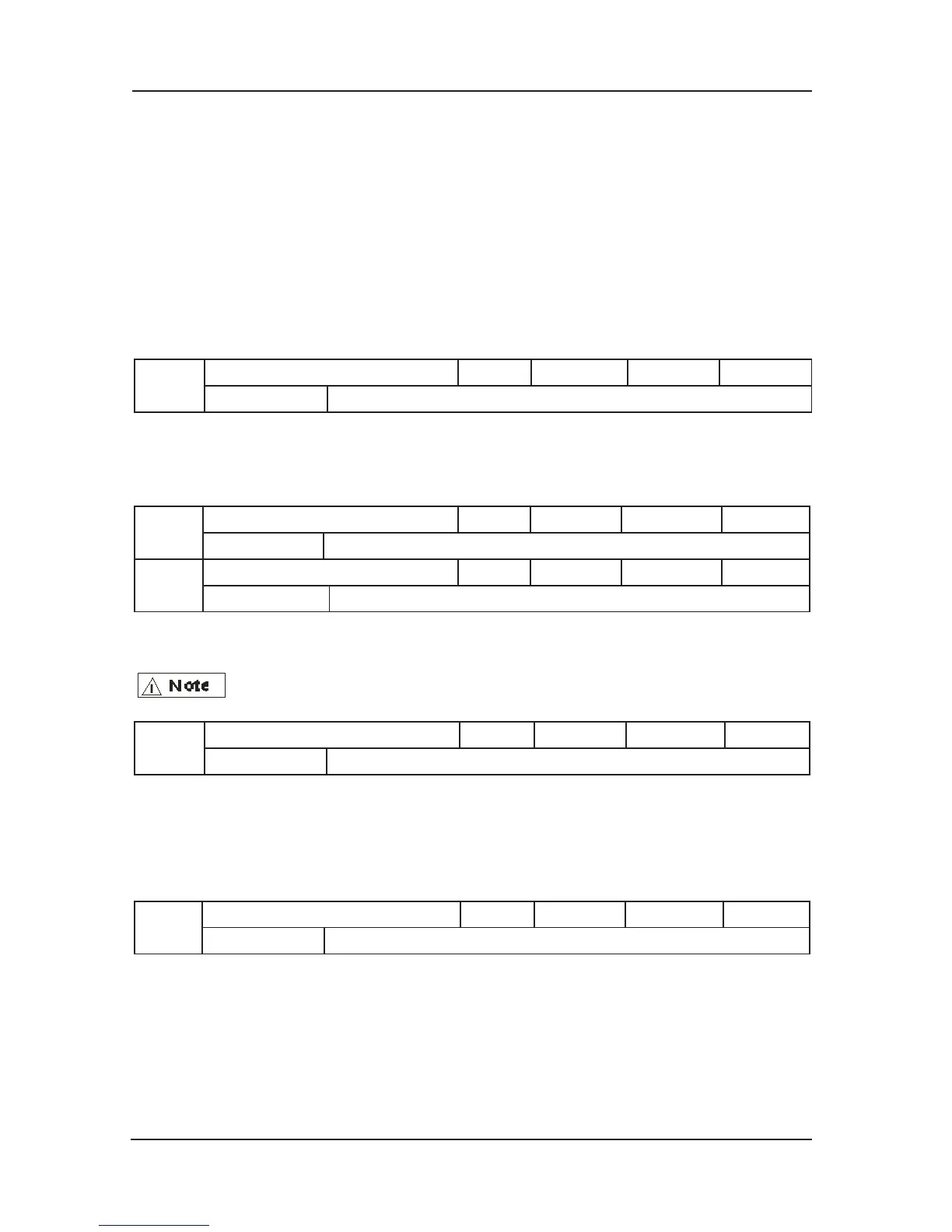

F8-06

Car no load setting Default 0 Min. Unit 1

Setting Range 0~1023

F8-07

Car full load setting Default 100 Min. Unit 1

Setting Range 0~1023

This group function codes can set the AD sampling value of analog when the car is in no load

and full load condition.

: If F8-06=F8-07, full load and over load is invalidation.

F8-08

Anti-nuisance function Default 0 Min. Unit 1

Setting Range 0、1

0:This function forbidden;

1:Allowable. This function must work with weighing sensor or weighing switch. If the car

order number is over the person number in car plus 3, the system clear up all orders, and each

person according to 70 Kg.

F8-09

Power failure rescue speed Default 0.050m/s Min. Unit 0.001m/s

Setting Range 0.000~0.100m/s

When the lift is in the emergency state, it will run to leveling position in the speed. Please note

that the speed shouldn’t be too high in the rescue course, or it may affect the normal work of

UPS. The speed is determined by the power of UPS.

Loading...

Loading...