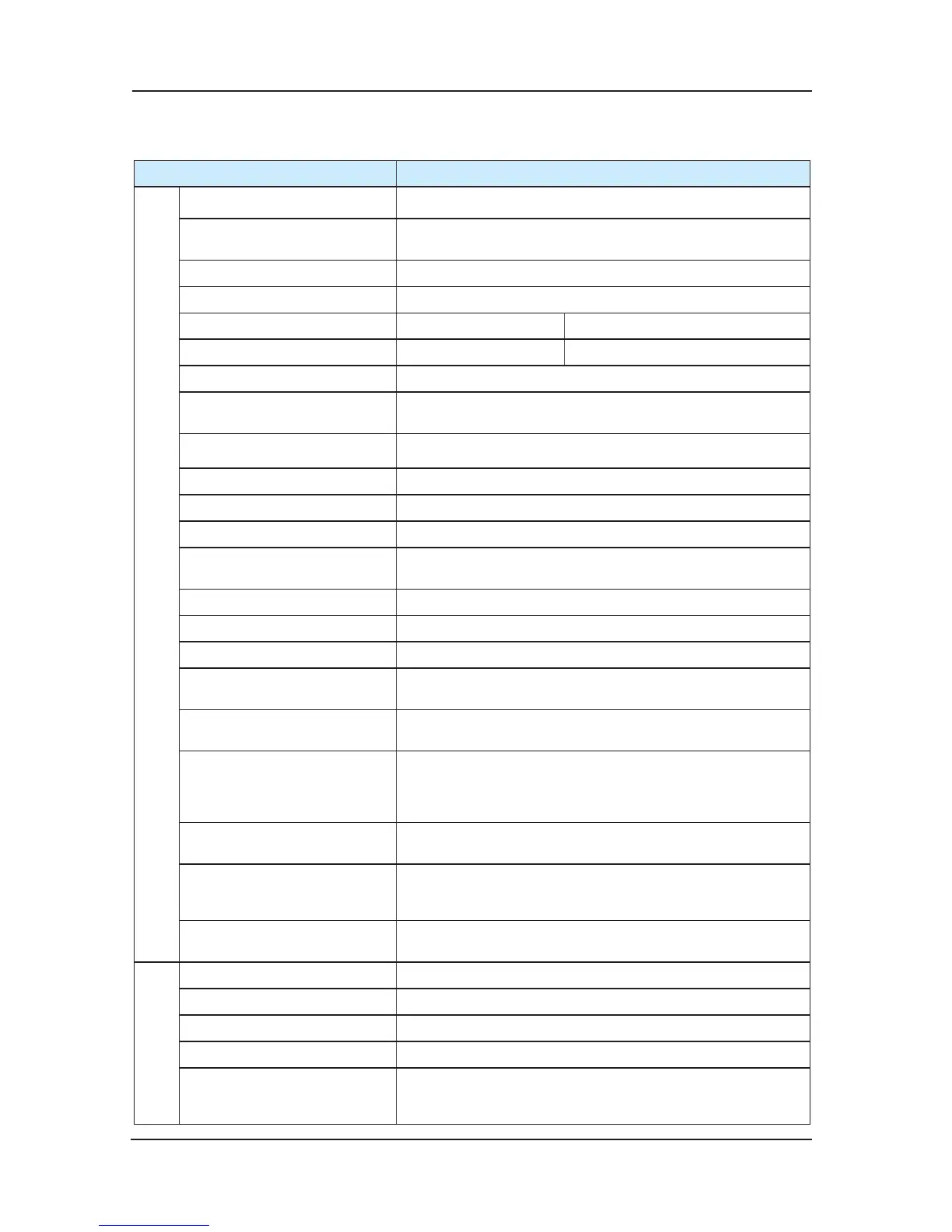

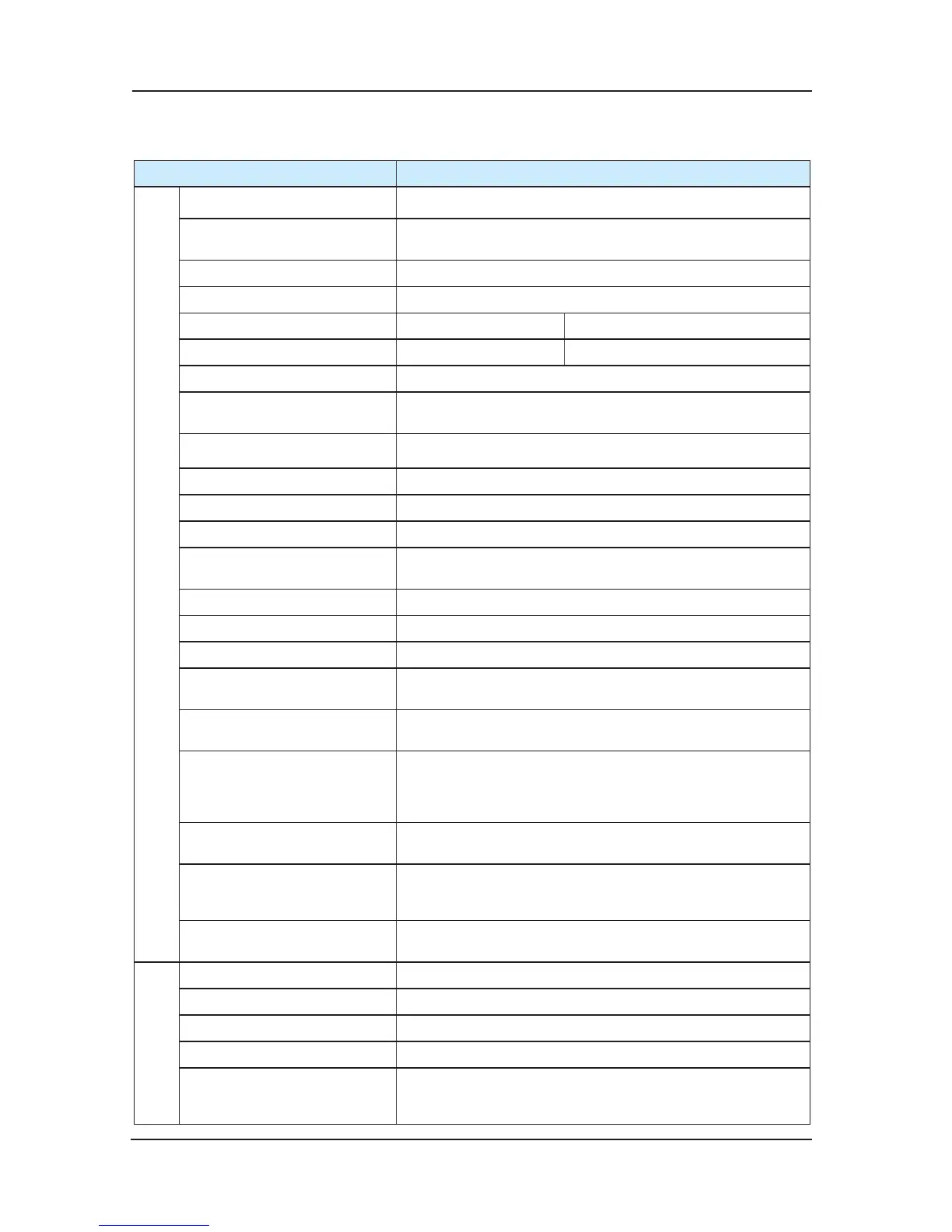

2.3 Technical Specification

Item Specification

Specification

Maximum frequency 90Hz

Carrier frequency

0.5k~16k (Hz); Carrier frequency can be adjusted

automatically according to the load characteristic.

Control mode

Split-ring vector control (SVC)/ Closed loop vector control (VC)

Start torque Type G: 0.5Hz / 180% (SVC), 0Hz/200% (VC)

Speed control range 1 : 100 (SVC) 1 : 1000 (VC)

Speed accuracy ±0.5%(SVC) ±0.05%(SVC)

Torque control accuracy ±5%(VC)

Overload capability

150% rated current for 60 seconds; 200% rated current for 1

second.

Motor tuning No-load tuning, load tuning

Distance control Immediacy stop

Acceleration/deceleration curve

N curves can generate automatically.

Re-leveling Level re-adjusts after the car load changes

Forced deceleration

New and reliable compulsive deceleration function helps to

identify the

deceleration shelf automatically.

Shaft auto-tuning 32-bit data, record the shaft position accurately.

Leveling adjustment Flexible and easy leveling adjustment function

Starting torque compensation Humanized weighing aito-tuning

Real time clock

Based on accurate real time clock, it can accomplish time-

sharing service, pinnacle service, automatic password, etc.

Testing function

Convenient ways to realize many functions for elevator

adjusting.

Failure protect

Provide 53 kinds of protection such as electrify short circuit

survey、in-out lack phase protect、over current protect、

prevent encoder and so on. A complete elevator fault-

dealing system

Intellectualized management

Fulfill the function of distance monitoring, user management,

and group adjustment.

Apply power then peripheral

equipment safety auto-

exami

nation

Apply power and do peripheral equipment detection like

grounding、short circuit etc.

State monitoring

According each feedback signal to judge elevator work

state, ensure the elevator work effectively.

Input/output

characteristic

Digital input 24 Digital input terminal,specification:24V,5mA

Analog data input A1 input terminal voltage range:-10V~10V

Communication terminal Canbus (car top) \ Modbus (hal

l call)

Output terminal 6 relay output terminal, adjustable function

Encoder interface

Standard adoptable to incremental push-pull output and

open-loop collector output. coder .

Applicable to different encoder via PG card.

Loading...

Loading...