2-10 PERIODIC MAINTENANCE

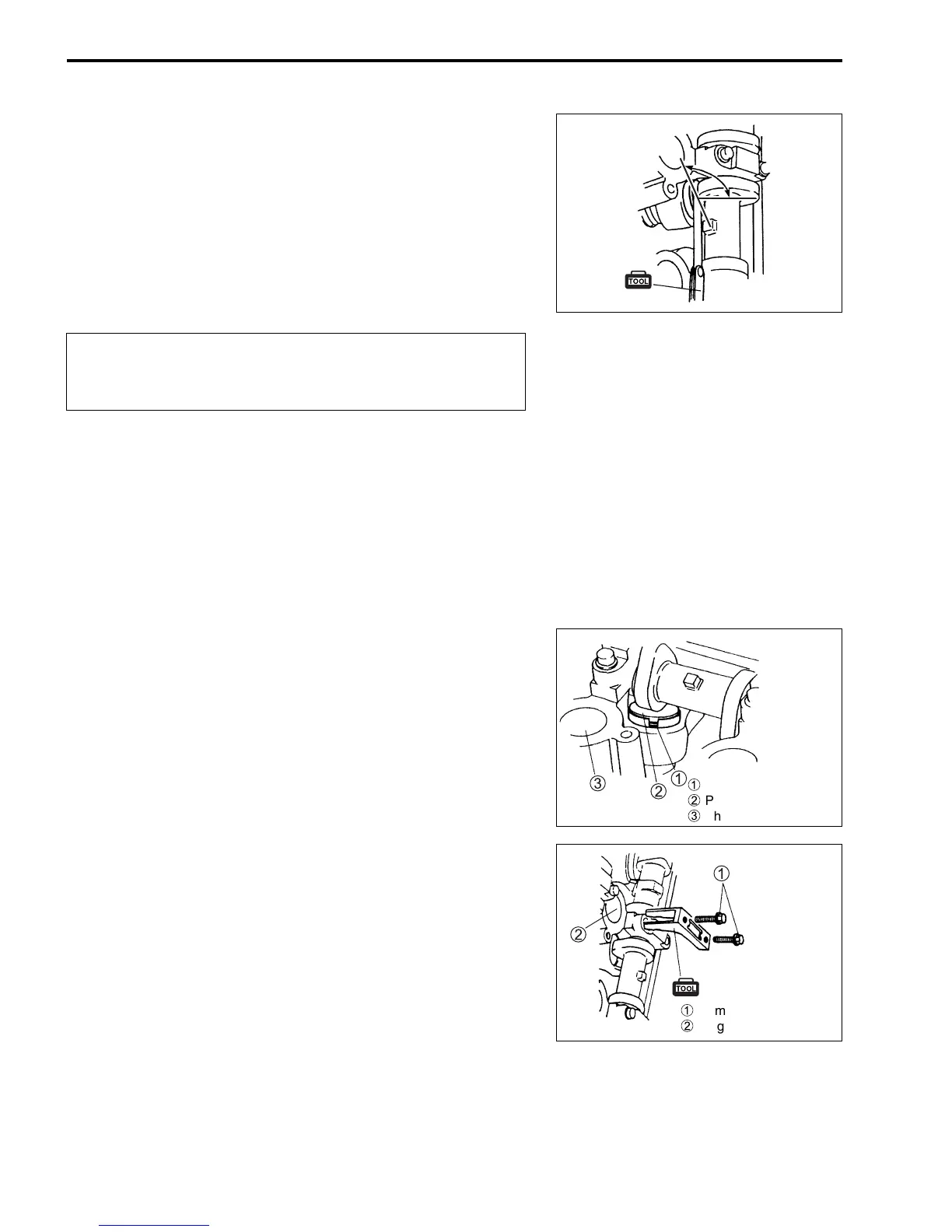

3. Rotate crankshaft counterclockwise to bring cam nose verti-

cal to shim surface.

4. Measure tappet clearances by inserting thickness gauge

between cam and shim surface.

Tappet clearance (cold engine condition):

IN.: 0.23 – 0.27 mm (0.009 – 0.011 in)

EX.: 0.30 – 0.34 mm (0.012 – 0.013 in)

! 09900-20803: Thickness gauge

#

NOTE:

• Rotate crankshaft and measure clearance for each tappet

respectively by bringing cam nose vertical to shim surface.

• All tappet clearances can be measured during two crankshaft

rotations.

5. If out of specification, adjust tappet clearance by changing

shim.

ADJUSTMENT

Tappet clearances are adjusted by replacing tappet shim.

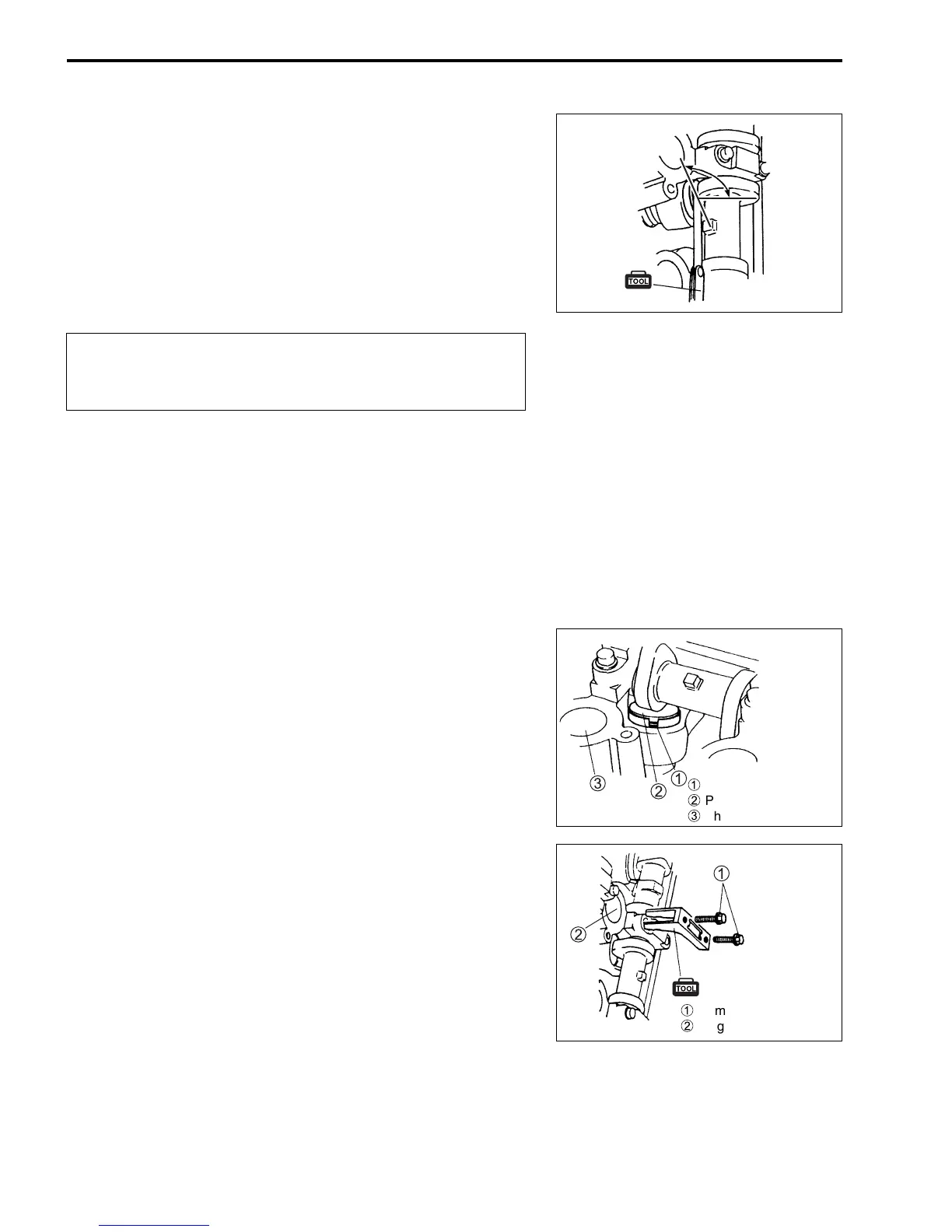

1. With cam nose vertical to valve, turn tappet cut-away

towards center of cylinder head as shown in figure.

2. Rotate crankshaft to open (lift up) valve and then remove

camshaft housing bolts where shim is to be replaced.

3. Install special tool with camshaft housing bolts as shown in

figure.

! 09916-69310: Tappet holder

This is left hand (LH) rotation powerhead.

Rotate crankshaft counterclockwise to prevent water

pump impeller damage.

90˚90˚

Cut section of the tappet

Plug hole

!

Shim

Camshaft housing bolt

Plug hole

Loading...

Loading...