PERIODIC MAINTENANCE 2-11

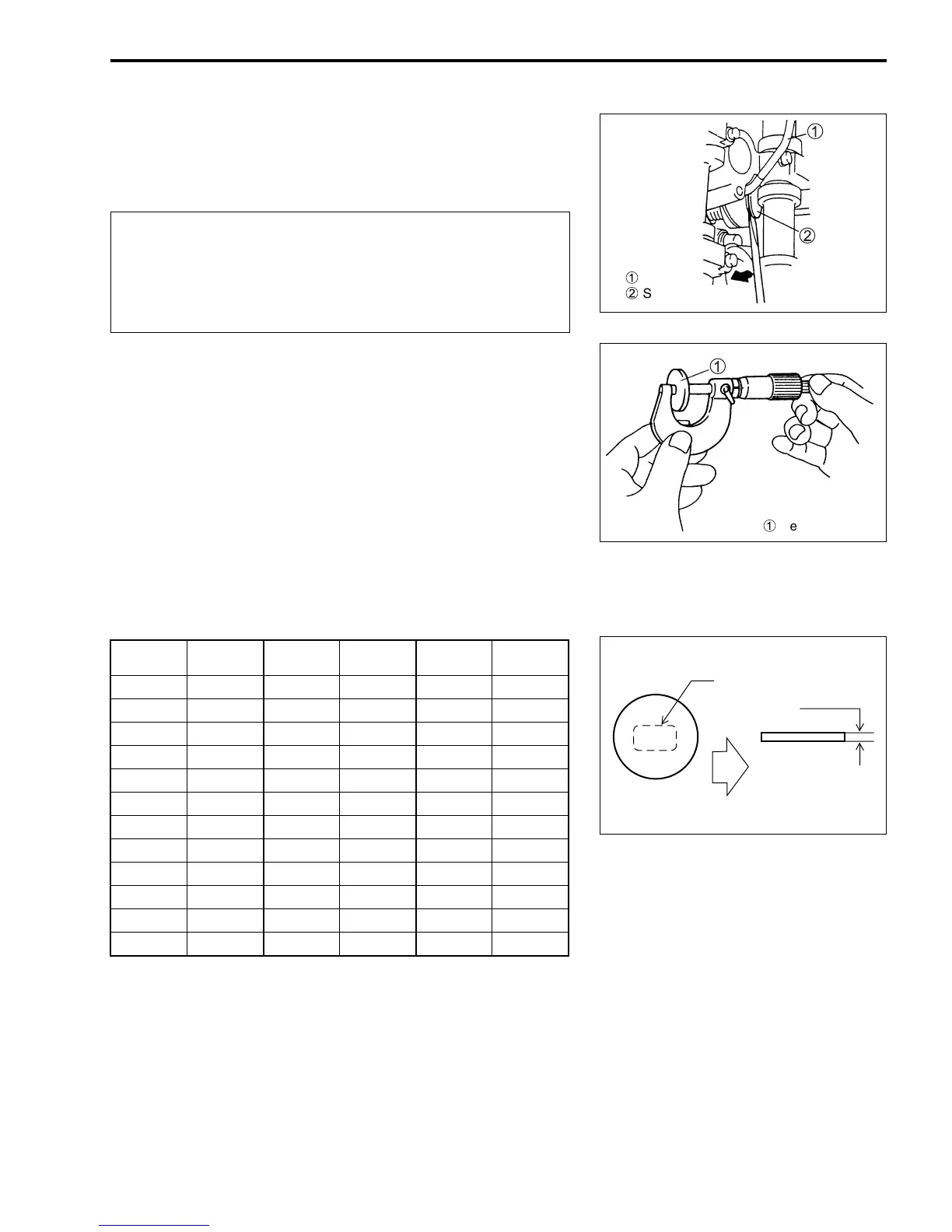

4. Rotate top of cam 90 degree counterclockwise and remove

shim from cut-away at tappet.

(Two tappets can be adjusted at the same time.)

#

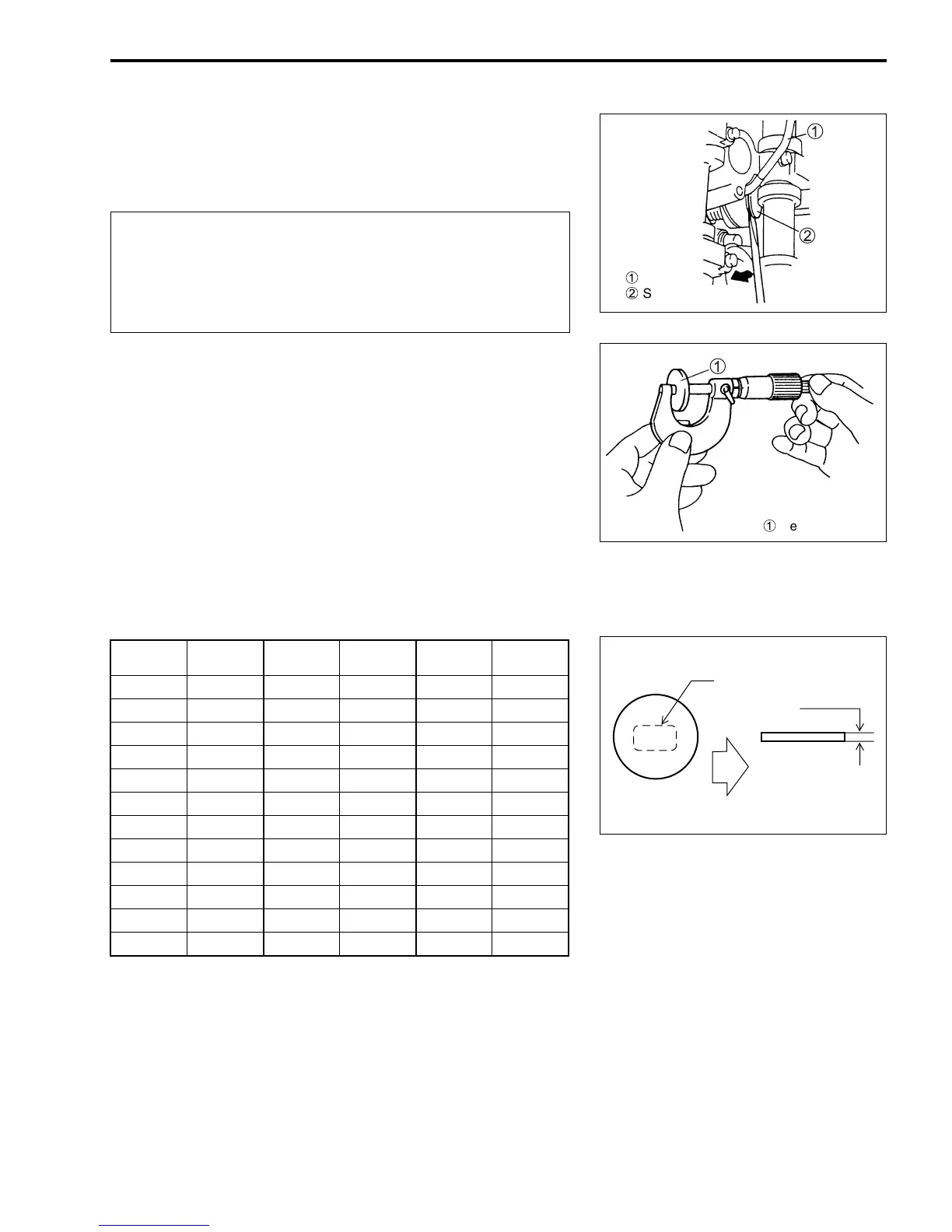

5. After removing shim, measure thickness of original shim and

determine correct thickness of shim for proper tappet clear-

ance as calculated by following formula.

! 09900-20205: Micrometer

IN. side:

A = B + (C – 0.25 mm)

EX. side:

A = B + (C – 0.32 mm)

A: Correct thickness of shim for proper tappet

clearance (mm)

B: Thickness of original shim (mm)

C: Original tappet clearance (mm)

• Do not put your finger between camshaft and tappet

while the tappet is being held with the tappet holder.

• Use a magnet to remove and install shim.

• When installing shim, identification mark on the

shim should face down (towards tappet).

Magnet

Shim

I.D No.

Thickness

(mm)

I.D No.

Thickness

(mm)

I.D No.

Thickness

(mm)

218 2.18 248 2.48 278 2.78

220 2.20 250 2.50 280 2.80

223 2.23 253 2.53 283 2.83

225 2.25 255 2.55 285 2.85

228 2.28 258 2.58 288 2.88

230 2.30 260 2.60 290 2.90

233 2.33 263 2.63 293 2.93

235 2.35 265 2.65 295 2.95

238 2.38 268 2.68 298 2.98

240 2.40 270 2.70 300 3.00

243 2.43 273 2.73

245 2.45 275 2.75

Removed shim

250

I.D No.

2.50 mm

Loading...

Loading...