SYNRAD® 32-1 Operator’s Manual Version 2.2

32

Technical Reference

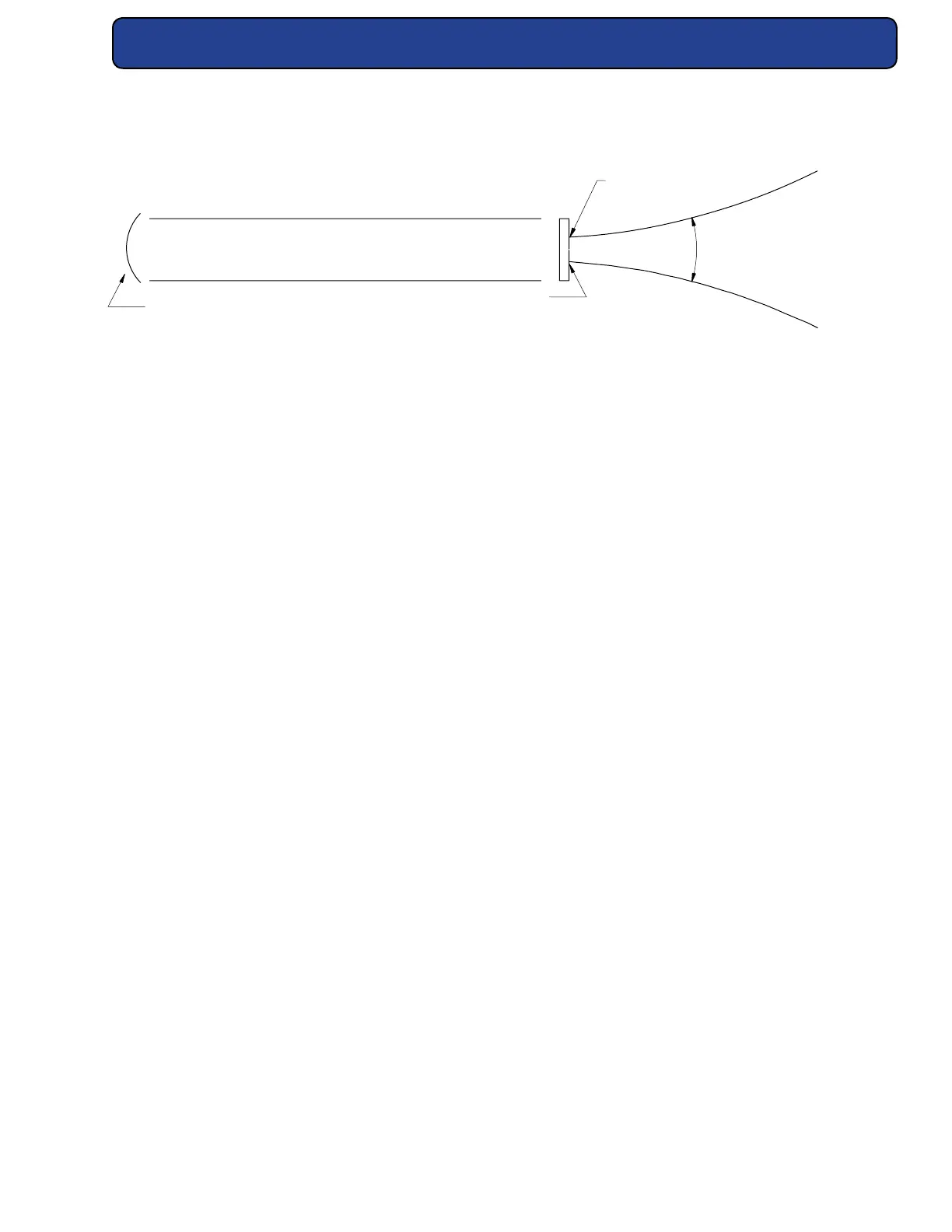

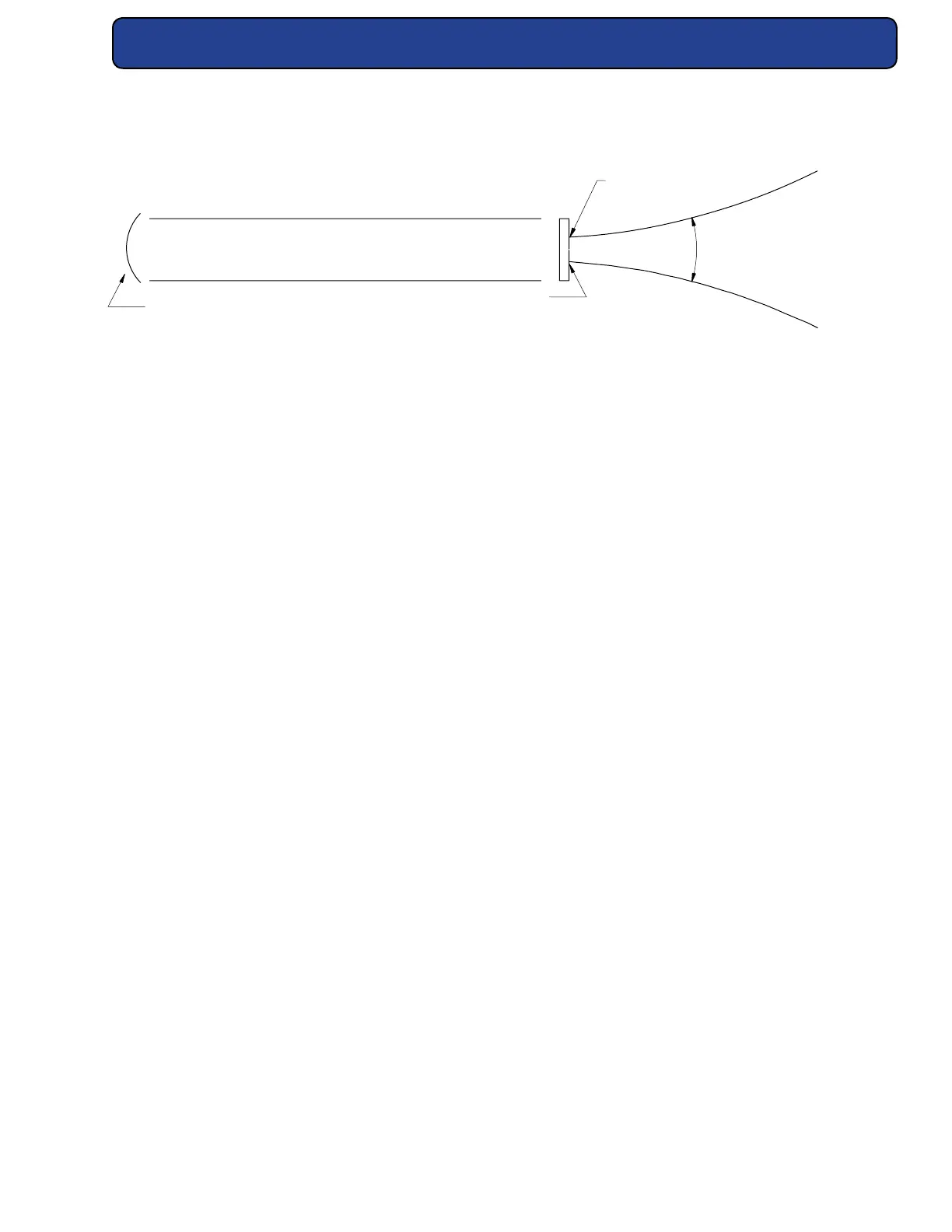

Ø

RF DISCHARGE REGION

TOTAL REFLECTOR

OUTPUT COUPLER

FULL ANGLE

BEAM WAIST DIA. 2.3 ± 0.5 mm

Figure 4-1 Beam characteristics.

Controlling Circuitry

Electrical description

Control of laser operation and power output levels is essentially performed using a single PCB.

The Control PCB connects the modulated signal to the RF amplier. It also provides electron-

ics to monitor performance of RF control, output circuitry, input power, temperature, PWM

accuracy, provides outputs to an externally accessible connector, and incorporates reverse

polarity protection.

Model 32-1 lasers use a single RF electrode requiring a single modulated RF drive input from

the Control PCB.

The modulated input PWM signal is generated externally to the laser and connected to the

input connector. This signal is connected to an optoisolator, the output of which is applied

to the PWM switch control circuit. The PWM switch control circuit gates the PWM switch o

and on at the frequency and duty cycle controlled by the modulation source. When the PWM

switch closes, a potential of +30 VDC is applied to the RF Driver. The PWM control circuit pro-

vides on/o gating of the PWM switch unless disabled by the ve-second delay, or the fault

shutdown circuits.

The ve-second delay disables PWM output to the RF amplier for a period of approximately

ve seconds after the Remote Keyswitch link is closed (power ON). Note that the supplied

DB-9 jumper plug can be removed to allow the user to insert a remotely located relay or

switch in series with the Remote Keyswitch.

Over temperature fault shutdown occurs when laser tube temperature reaches 60 °C ±2 °C.

Control board operation begins when the supply voltage rises above +18 VDC and remains

below +36 VDC. After start-up, the control board will shut the laser down if supply voltage

falls below +15 VDC or rises above +36 VDC.

Loading...

Loading...