4 systemair

1.3 General description

KA air handling units are modular devices that may be manufactured for a number of combinations of different cross

section dimensions, functional unit assemblies, material combinations, sizes and types of control. Depending on

the particular version, KA air handling units are designed for comfort ventilation, clean room ventilation, indoor pool

ventilation, ventilation of industrial premises, and areas with an explosive atmosphere.

The variety of available dimensions, shapes and constructions of KA air handling units allows them to be installed

indoorsontheoor,onaplatform,orbelowtheceiling;theymayalsobeinstalledoutdoors.

The casing of an air handling unit of the normal or hygienic type consists of a thermally insulated and sound-insulated

aluminium frame, thermally insulated and sound-insulated sheet covers at the bottom, top and sides, a door on the

serviceside,andasteelbaseframetowhichlegscanbettedifsorequired.Thethicknessoftheairhandlingunit

casing wall is 50 mm.

Comfort units

With a normal type of air handling unit, all the interior and exterior casing walls are made of ZM-coated galvanised

steel sheet as the standard. The whole bottom of the unit is sealed on the inside between the frame and panels. The

fastening material is of galvanized steel quality.

Hygienic units

Asastandard,thefrontandbackwallsandtheceilingaremadeofpaintedsteelsheet,whilethebottom,guiderails

and all partition walls are made of 1.4301 stainless steel sheet. All the joints between the frame and panels are sealed

in the inside with clean-room-grade putty. The fastening material is of A2 or Ruspert quality.

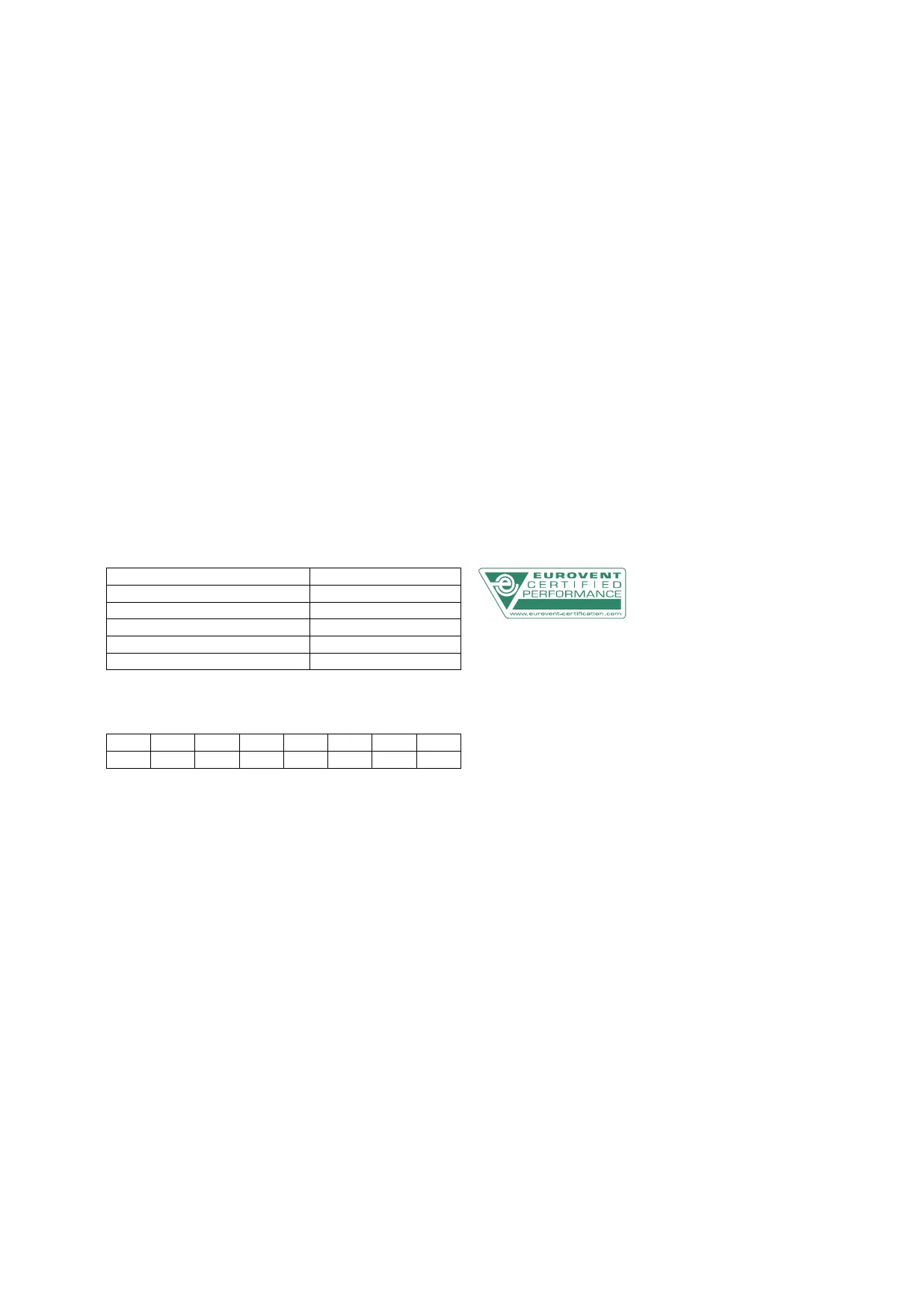

Casing technical properties according to EN 1886

Mechanical stability D1

Thermal transmittance factor T2

Thermal bridge factor TB2 or TB3

Casing air leakage class (+700 Pa) L2

Casing air leakage class (-400 Pa) L2

Filter bypass leakage class F9

Casing sound attenuation

Casing with fully glued panels:

Hz 125 250 500 1000 2000 4000 8000

De dB 15 12 16 13 27 32 41

Loading...

Loading...