6-8

OPERATING PROCEDURES

Models 60 and 62

Operating Procedures

6

3. Place the control switch in the AUTO position.

Figure 6-32

4. To initiate freeze down, rotate the draw valve to the

right so it is disengaged from the draw arm. Lift the

draw arm momentarily. This will start the freezing

cycle. Lower the draw arm and re-engage the draw

valve. When the machine cycles off, the product is

ready to serve.

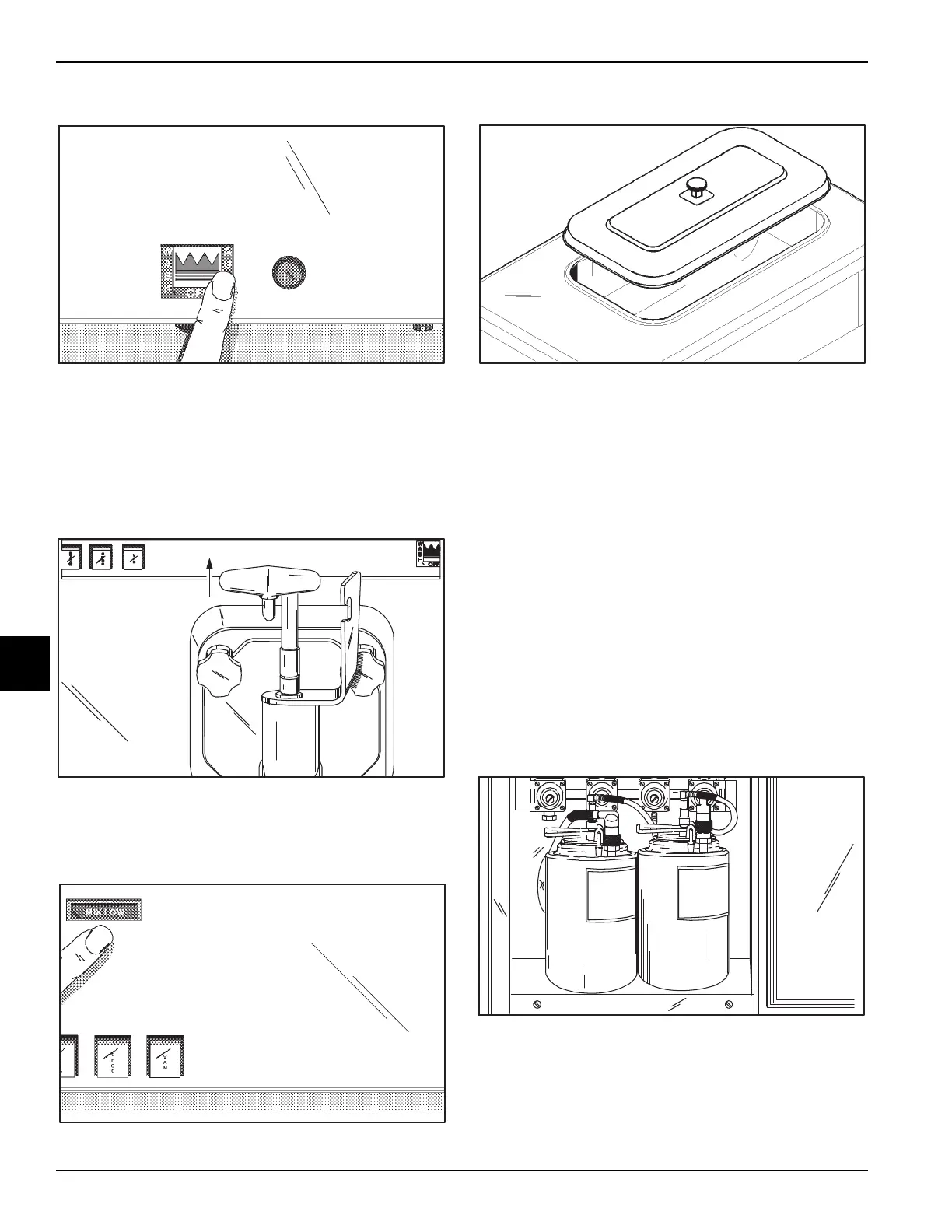

Figure 6-33

5. Fill the mix hopper with mix. As the mix level comes

in contact with the mix sensing probe on the rear wall

of the hopper, the MIX LOW light will stop flashing.

Figure 6-34

Place the mix hopper cover in position.

Figure 6-35

Syrup System

Two main objectives in the opening procedures are:

1. Fill the syrup tanks.

2. Calibrate the syrup flow.

The syrup system must be checked daily to ensure a

high-quality shake.

Important! Use only single-strength syrup that is free of

pulp and seeds.

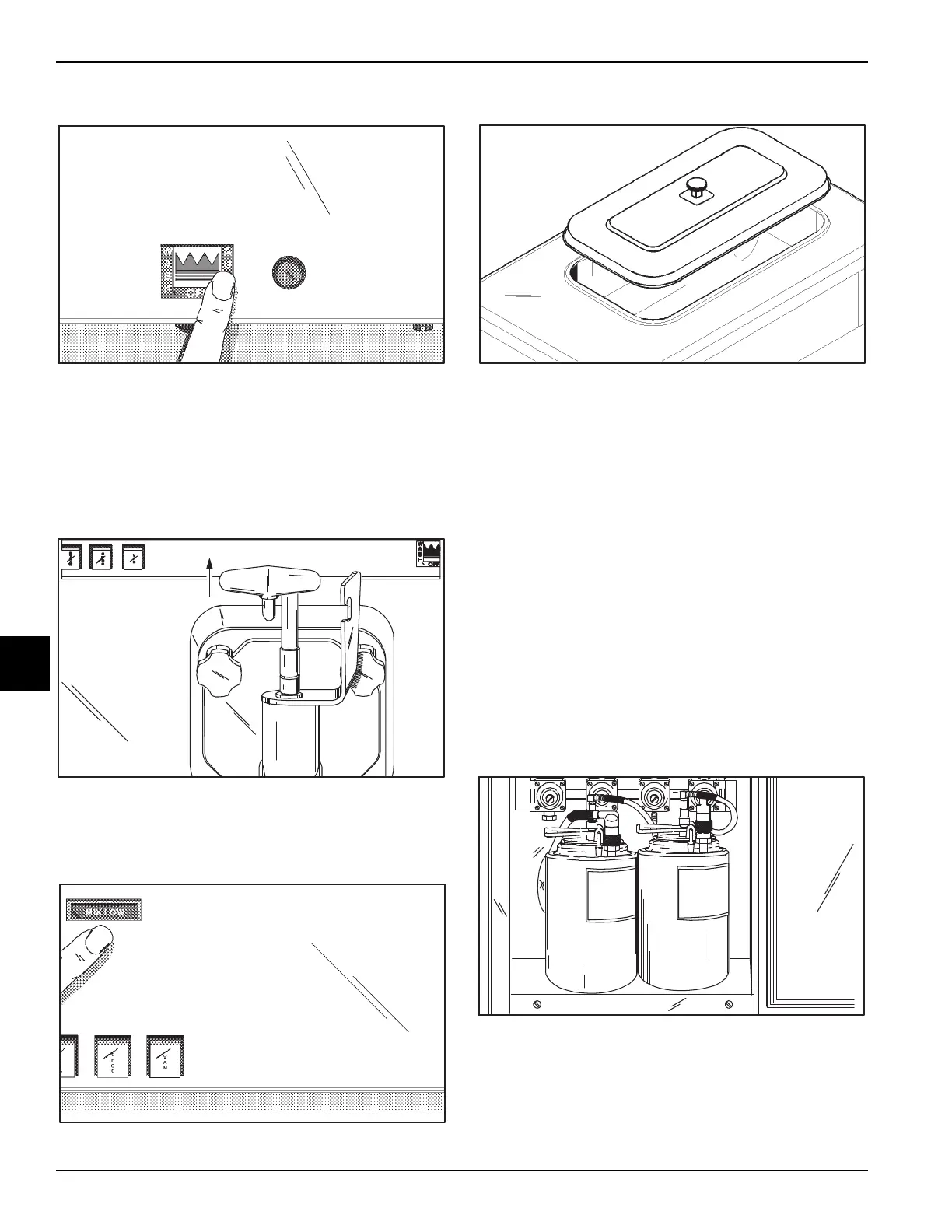

Model 60

The syrup tanks are in the lower front syrup cabinet. The

air lines and syrup lines are color spiral wrapped. Make

sure to match the color-wrapped air and syrup line to the

correct flavor syrup tank.

Figure 6-36

Loading...

Loading...