(s) either remove the blades or wrap the crossbeater(s)

in old carpet or hessian sacking.

It is not necessary to remove the crossbeater(s) to

replace the bearings.

Before the crossbeater(s) can be removed, remove the

large top cover and the left hand hinged drive chain

guard.

Release the chain tension on the side drive chains and

remove them. The sprocket and bearing can now be

removed from the input shaft of the beater to be

removed. Loosen the grub screws retaining the

bearings on the shafts before removal.

SINGLE BEATER

To replace the crossbeater, it will be necessary to

remove the bale restraint assembly. To do this, release

the bolts at each end of the bale restraint beam.

Suspend the assembly with a suitable lifting device and

remove.

Loosen the grub screws retaining the bearings on the

shafts at the other end of the beaters. Now remove the

right hand mid body panel. With the mid body panel

removed, the crossbeater can now be withdrawn from

the machine.

Refitting is a reverse of the above.

TWIN BEATER

To replace either crossbeater, it will be necessary to

remove the bale restraint. To do this, release the

retaining washers at the ends of the pivot shaft and

remove the bale restraint mount from the right hand end,

making sure the bale restraint is well supported. Slide

the bale restraint out of the mount at the left-hand end.

With the upper crossbeater supported by a suitable

lifting device and the lower crossbeater supported on

blocks. Loosen the grub screws retaining the bearings

on the shafts at the other end of the beaters. Now

remove the right hand mid body panel.

With the mid body panel removed, the upper cross

beater can now be withdrawn from the machine. The

lower crossbeater can now be removed.

Refitting is a reverse of the above.

ROTOR REMOVAL

First, remove the front drive guard, valve guard, housing

top and hose support. Release the hoses to the chute-

operating ram. Wedge the rotor to prevent rotation and

unscrew the bolt in the centre of the rotor. Support the

bottom of the gearbox and secure it with a rope so that

when it is released it does not fall. Remove the 11 bolts

retaining the rotor gearbox.

Suspend the rotor from a lifting device so that it can be

removed safely. The rotor is located on a taper and will

usually require a special tool to remove the rotor from

the gearbox. This tool is available from the

manufacturer.

Lift the rotor clear of the housing

Refitting is a reverse of the above.

CROSSBEATER SHEAR BOLTS

To replace the shear bolt, open the hinged left hand

drive guard to gain access to the shear sprocket.

Grease the sprocket hub before replacing the shear bolt.

One Grade 10.9 M8 x 50 bolt should be fitted.

GEAR BOX

After 50 hours of use the gear box oil should be drained

and replaced with new oil. To drain the oil, remove the

valve guard, remove the drain and filler plugs and allow

it to empty. Waste oil should be collected and disposed

of at an oil recycling facility

Refill the gearbox with SAE90.EP gearbox oil. The oil

capacity of the gearbox is 4.7ltrs (1.25 Gallon).

DRIVE CHAINS

Apply chain lubricant or oil weekly to these chains.

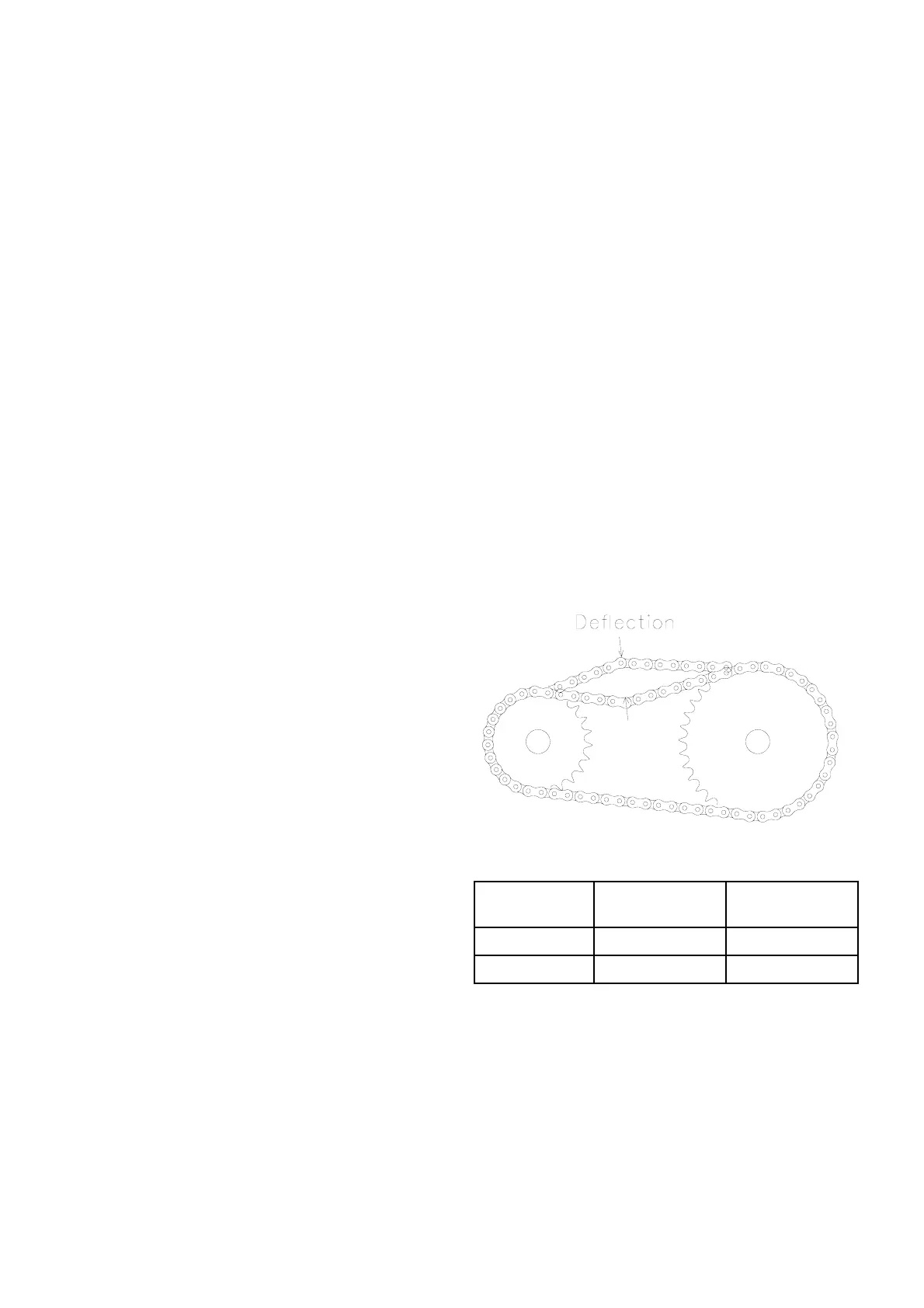

To tension the bed chain drive on the 8080 models,

remove the guard covering the chain, release the 4

clamp bolts on the motor mounting plate. Using the

tensioning bolt provided jack the motor mounting plate

until the chain has 12mm movement midway between

the sprockets (see figure 4).

To tension the crossbeater chain drive, remove the

shear sprocket cover from the left hand chain guard.

Release the clamp bolt and reposition the relevant

tensioner so that there is the correct movement

midway between the sprockets on the opposite side to

the tensioner (see figure 4 and table 2).

Figure 4 Chain tension.

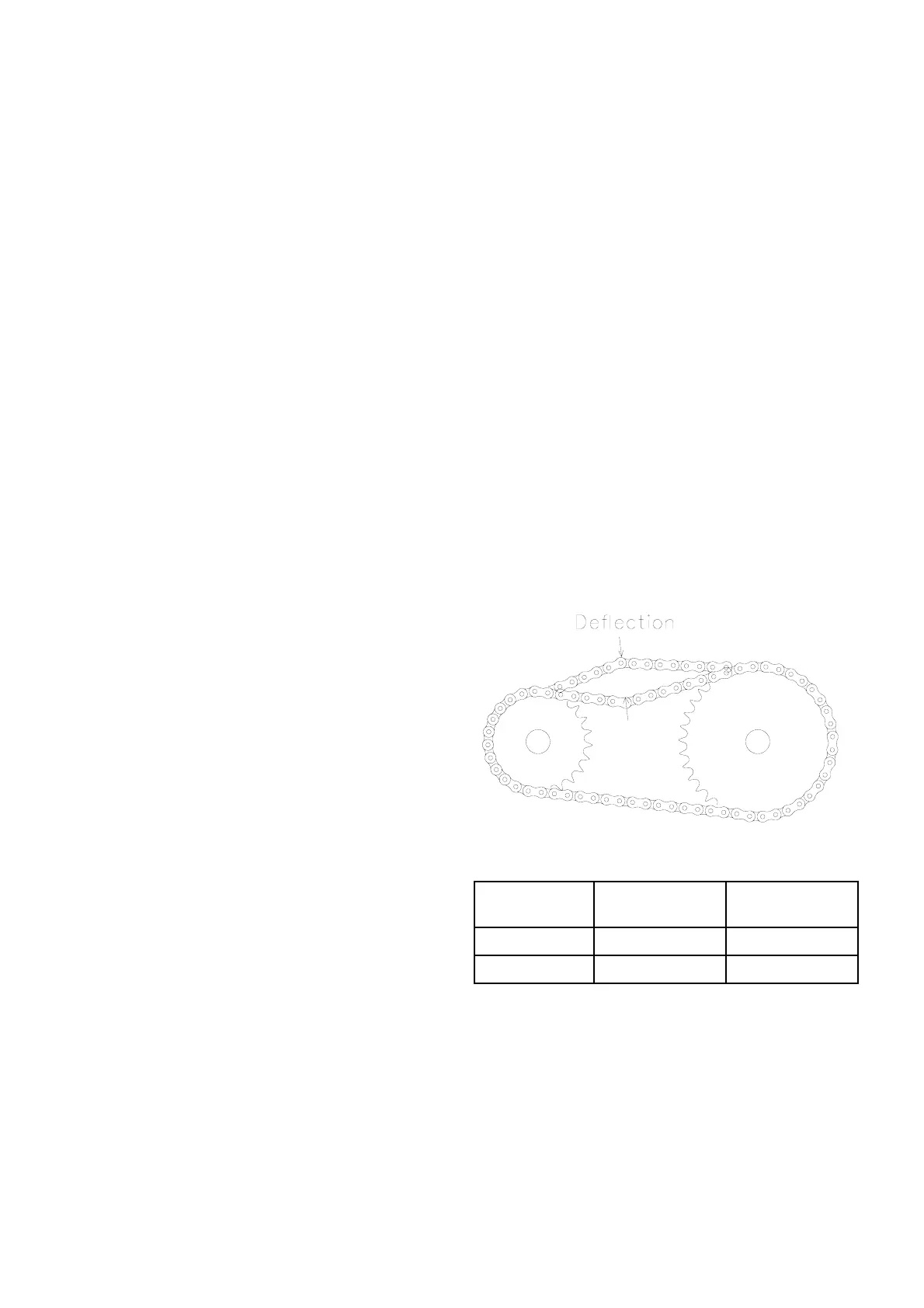

Table 2 Chain deflection

SWIVEL CHUTE

The chute is rotated by means of a gear and ring gear.

It is important that this is well greased. To apply

grease to the ring gears there are 4 nipples on the

clamp plates.

The deflector ram has 2 grease nipples, one on each

pivot bush.

Drive Chain Single Beater

Deflection mm

Twin Beater

Deflection mm

Outer drive 15 15

Cross beater - - - 12

8

Loading...

Loading...