Theory of operation

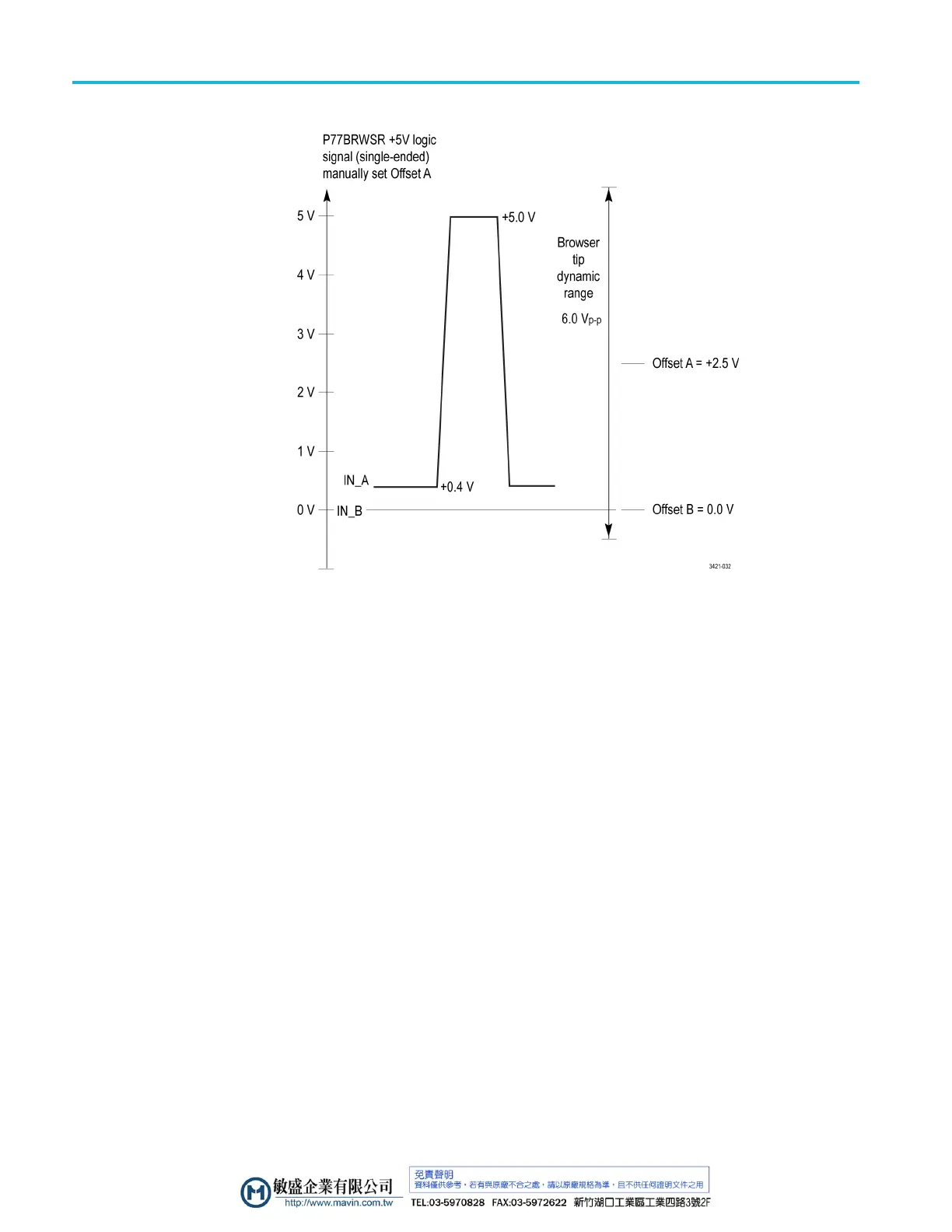

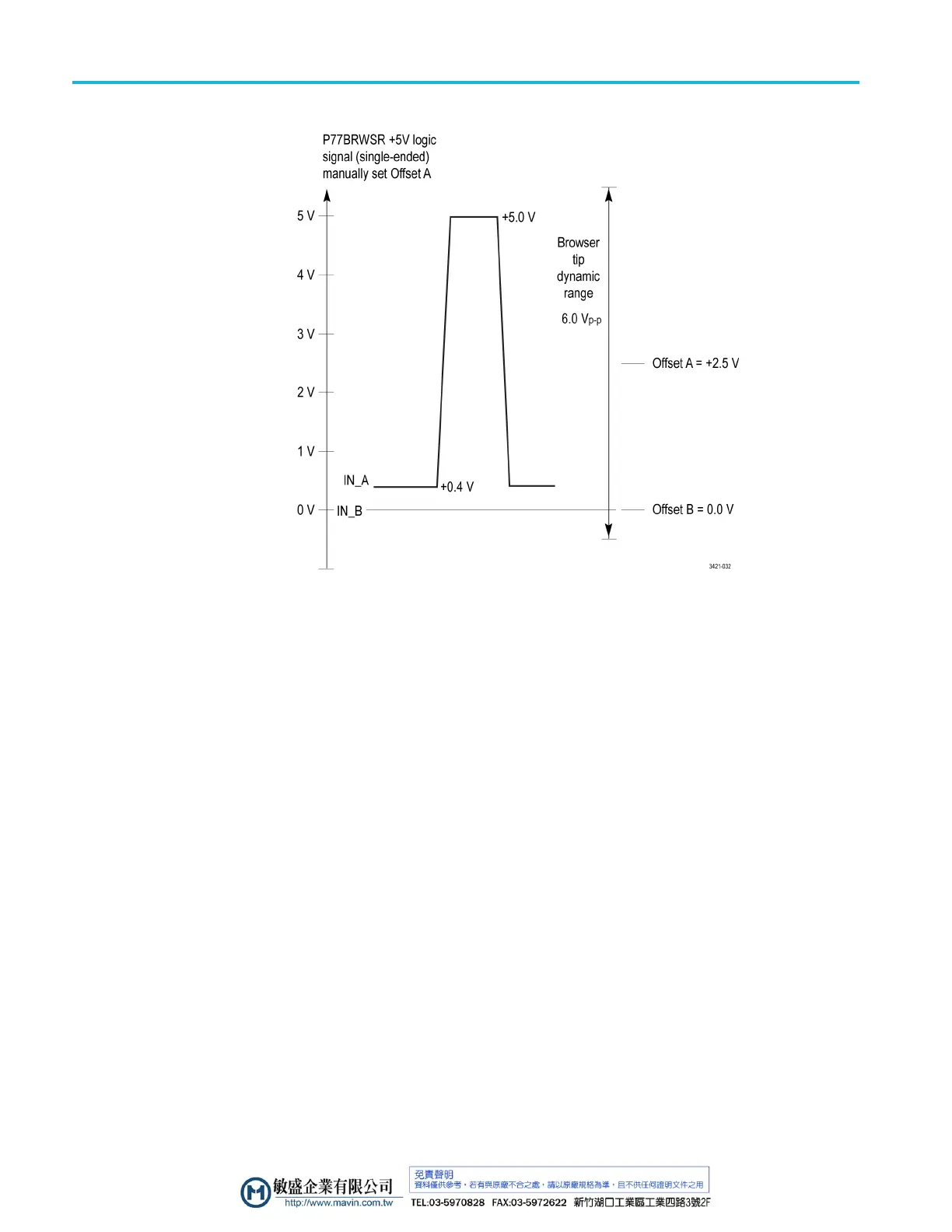

Figure 19: Differential input mode signal voltage and offset voltage

The configuration process described in this section maximizes the a vailable

dynamic range of the P77BRWSR tip when making single-ended measurements.

Temperature

compensation

The P7700 Series probes employ temperature compensation to optimize

measurement accuracy. Whenever a probe setting is changed, such as Input

Mode, offset voltage, or vertical scale factor, a temperature compensation update

occurs. Continuous temperature compensation is not done to avoid introducing

noise into the probe amplifiers.

To maximize measurement accuracy when the probe is first powered on from a

cold start condition, you must allow a 20 minute warm-up period for the probe

and oscilloscope. After the warm-up period, you should adjust or toggle a probe

setting, such as the vertical scale factor, to trigger the temperature compensation

update.

Otherwise, a cold tempe rature compensation value might be used, which

would result in a small gain error.

Solder tip measurement

configuration

In many of the high-frequency signaling standards that the P7700 Series probes

are designed for, a 50 Ω termination at the transmitter is in parallel with another

50 Ω termination at the end of the transmission line path, effectively making

a25Ω signal source impedance. In this application, the solder tip adapter

measurement configuration is designed to pick off the transmitted signal at a

location in the signal transmission path.

28 P7700 Series TriMode Probes Technical Reference

Loading...

Loading...