DRAG-GUN PLUS 35C

Manual 0-4750 1-1 Introduction

SECTION 2:

INTRODUCTION

2.01 INTRODUCTION

Plasma is a gas which has been heated to an extremely high

temperature and ionized so that it becomes electrically con-

ductive. The plasma arc cutting process uses this plasma to

transfer an electrical arc to the workpiece. The metal to be cut

is melted by the heat of the arc and then blown away.

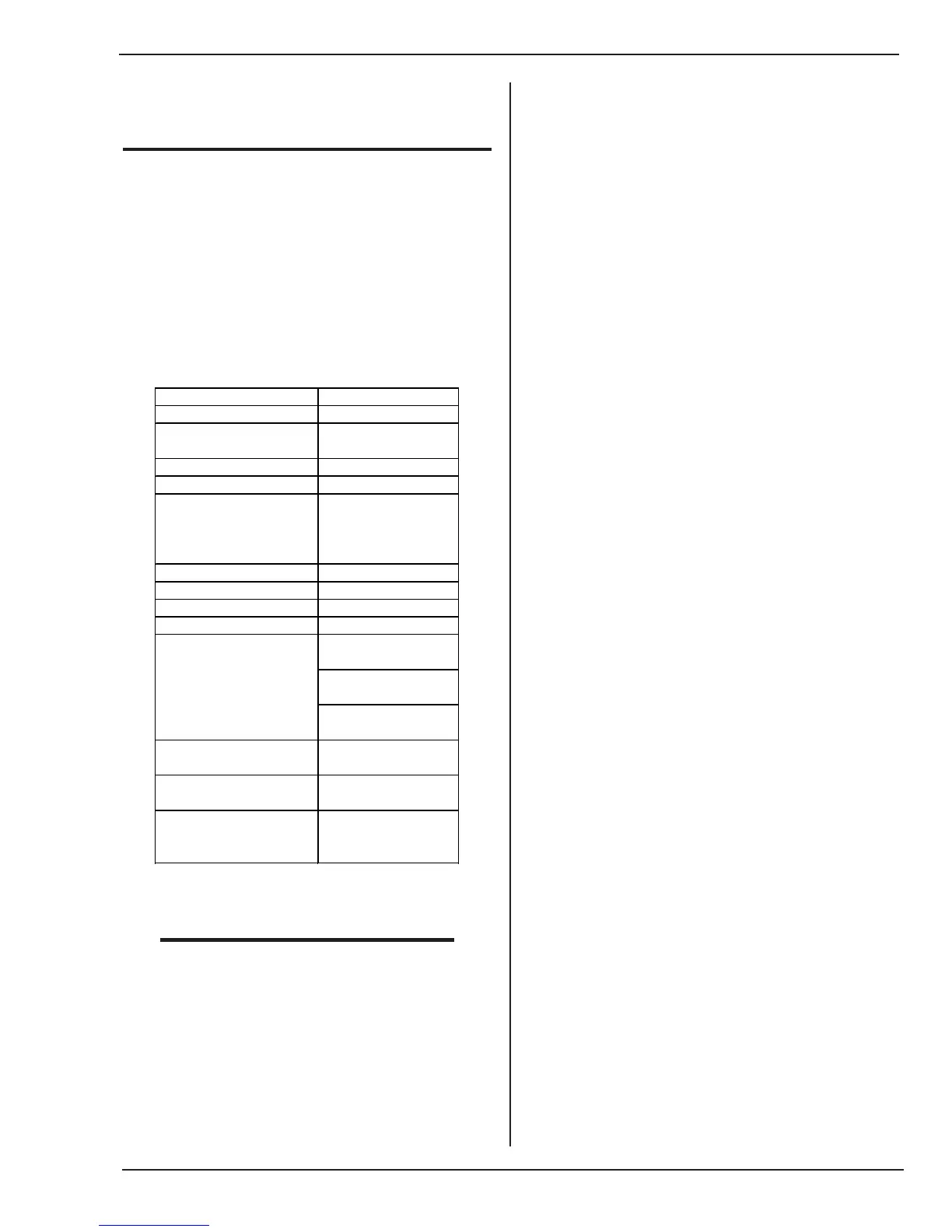

2.02 GENERAL SPECIFICATION

Model Description Drag-Gun Plus

Maximum output 35 Amps

Input Voltage & Phase

230V,

Single Phase

Frequency 50/60Hz

Input power 8.3 kVA

Current Input fuse

U.S. / Canada

40 Amps

All others 20A Slow

Blow Fuse

No Load Voltage 330V

Load Voltage 94V

Output Current 10 - 35 Amps

Post flow time 15 Seconds

35% @ 35A @

94vdc

60% @ 27A @

91vdc

100% @ 20A @

88 vdc

Genuine Cutting

Capacity

3/8"

(9 mm)

Maximum Cutting

Capacity

1/2"

(12mm)

Dimension (W * D * H)

10.5"x15.5"x11"

(267 mm x 394 mm

x 279 mm )

Duty cycle @ 104°F /

40° C Ambient

NOTE:

Refer to Local and National Codes or local au-

thority having jurisdiction for proper wiring re-

quirements.

2.03 Features

• COMPACT and LIGHT - Designed for easy transporta-

tion.

• ENERGY EFFICIENCY - Advanced technology reduces

power consumption.

• HIGH SPEED GENUINE CUTTING - The constricted

plasma arc provides high speed cutting as well as a

good quality genuine, narrow cut.

• LOW COST WITH COMPRESSED AIR - The Drag-Gun

Plus operates on compressed air.

• ALL KINDS OF METALS - Useful for most metals such

as stainless steel, aluminum, mild steel, copper and their

alloys.

• PILOT ARC IGNITION FROM TORCH - The Pilot Arc ig-

nites the cutting arc.

• POWERFUL CUTTING PERFORMANCE - Genuine cut-

ting capacity is 3/8” (9 mm).

• ABLE TO CUT PAINTED MATERIALS - Pilot Arc ignition

allows the Drag-Gun Plus to cut painted materials.

• EXTENDED PARTS LIFE - Consumable parts life is

longer.

Loading...

Loading...