Manual 0-2844 3-7 INSTALLATION PROCEDURES

C. Remote Pendant Control (Optional)

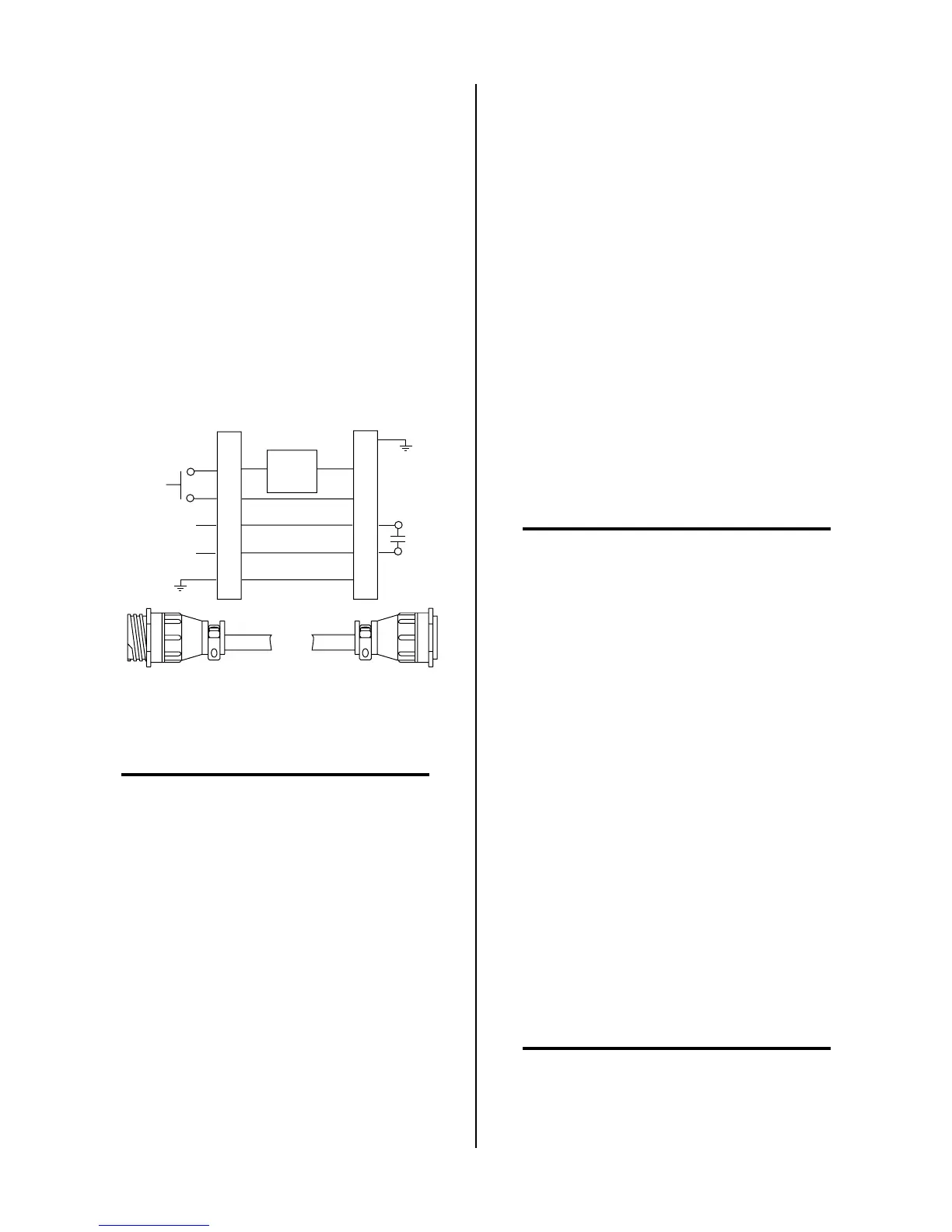

In machine type operations the Power Supply has an

Adapter that has a cable connector supplied at each

end of the Adapter. One end is connected at the fac-

tory to the mating connector on the Power Supply

Bulkhead area. The other end allows connection of a

Remote Pendant. The remote pendant lead connector

allows connection to a remote pendant or CNC cable

while using Control (PIP) Circuit connections in the

Torch Assembly.

Connect the remote pendant control cable to the con-

nector provided on the Adapter from the Power Sup-

ply.

2

3

4

12

14

13

Torch Control

Cable Connector

Remote Pendant/CNC

Cable Connector

PIP

Circuit

Control

OK-To-Move

3

4

12

14

13

A-01366

Remote Pendant Connector Diagram

NOTE

Refer to Appendix 3, Torch Control Cable Wiring

Diagram For Mechanized Systems, for detailed

schematic of the Adapter.

3.08 Ground Connections For

Mechanized Applications

A. Electromagnetic Interference (EMI)

Pilot arc initiation generates a certain amount of electro-

magnetic interference (EMI), commonly called RF noise.

This RF noise may interfere with other electronic equip-

ment such as CNC controllers, remote controls, height con-

trollers, etc. To minimize RF interference, follow these

grounding procedures when installing mechanized sys-

tems:

B. Grounding

1. The preferred grounding arrangement is a single point

or “Star” ground. The single point, usually on the

cutting table, is connected with 1/0 AWG (European

50 mm

2

) or larger wire to a good earth ground (refer to

paragraph ‘C’, Creating An Earth Ground). The

ground rod must be placed as close as possible to the

cutting table, ideally less than 10 ft (3.0 m), but no more

than 20 ft (6.1 m).

NOTE

All ground wires should be as short as possible.

Long wires will have increased resistance to RF fre-

quencies. Smaller diameter wire has increased re-

sistance to RF frequencies, so using a larger diam-

eter wire is better.

2. Grounding for components mounted on the cutting

table (CNC controllers, height controllers, plasma re-

mote controls, etc.) should follow the manufacturer’s

recommendations for wire size, type, and connection

point locations.

For Thermal Dynamics components it is recommended

to use a minimum of 10 AWG (European 6 mm

2

) wire

or flat copper braid with cross section equal to or greater

than 10 AWG connected to the cutting table frame. The

connection point must be clean bare metal; rust and

paint make poor connections. For all components,

wires larger than the recommended minimum can be

used and may improve noise protection.

3. The cutting machine frame is then connected to the

“Star” point using 1/0 AWG (European 50 mm

2

) or

larger wire.

4. The plasma power supply work cable (see NOTE) is

connected to the cutting table at the single point “Star”

ground.

NOTE

Do Not connect the work cable directly to the ground

rod.

Loading...

Loading...