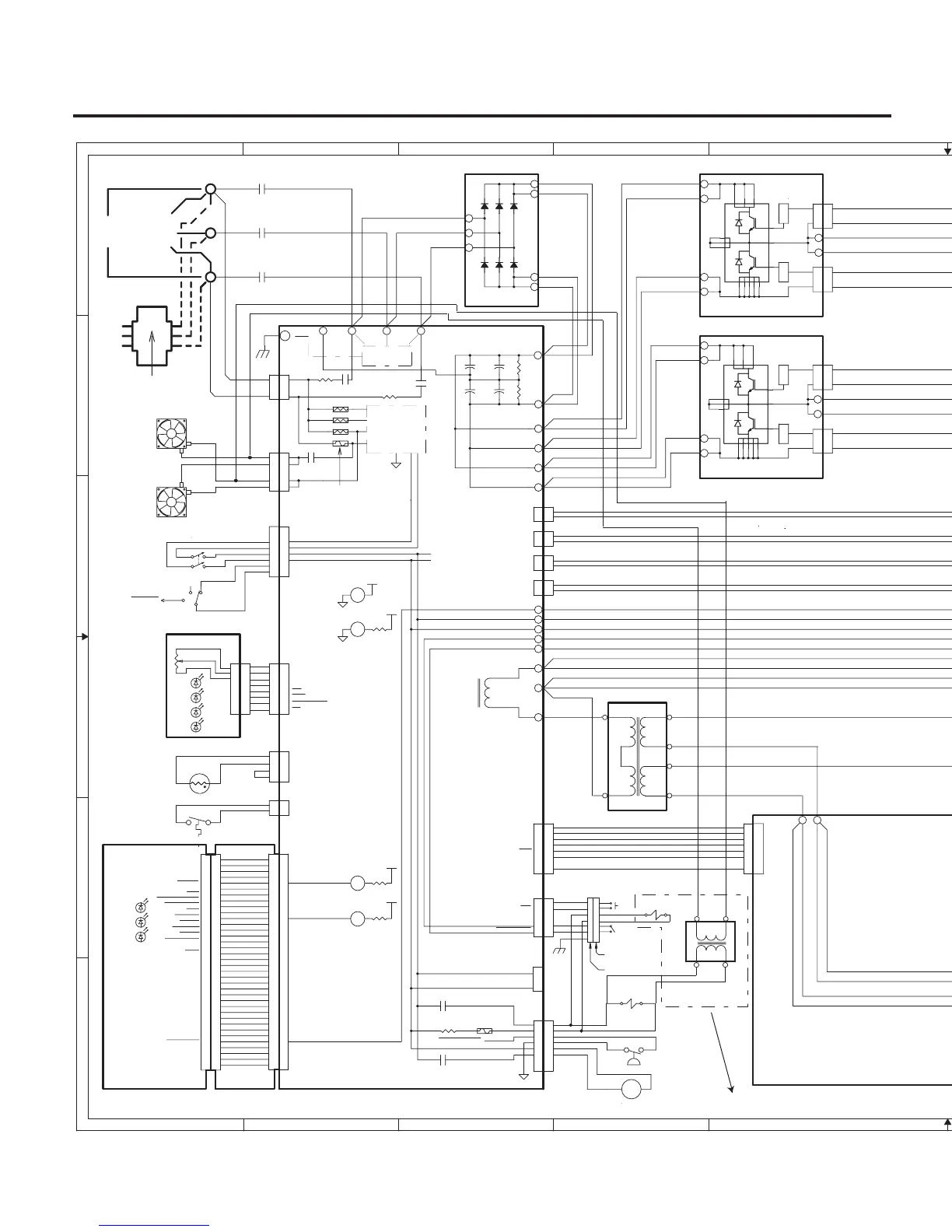

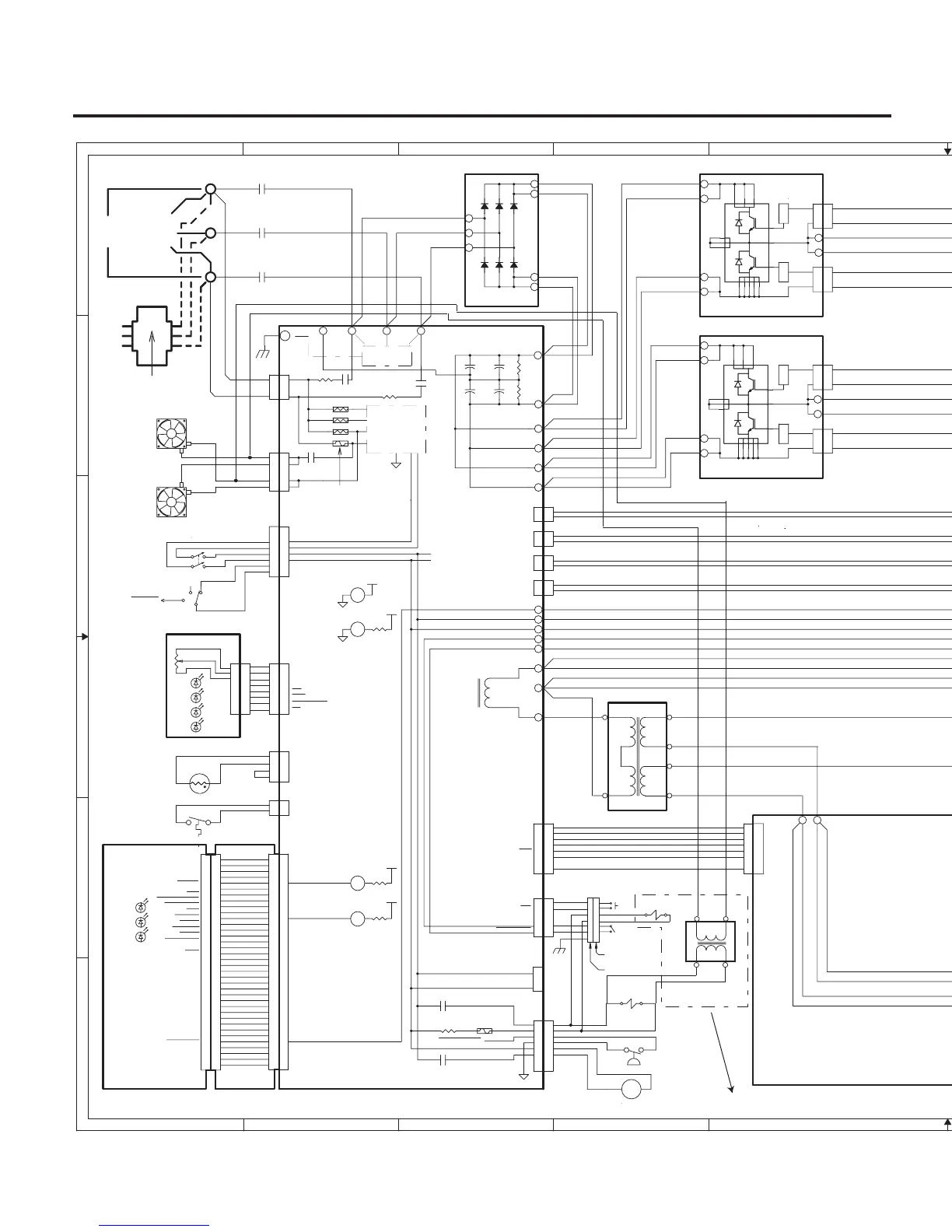

APPENDIX A-8 Manual 0-2956

APPENDIX 7: SYSTEM SCHEMATIC, 400 / 460- VOLT UNITS

1

1

2

2

3

3

4

4

5

5

A

B

C

D

E

F

+12VDC

+18V

+18V

+18V

415/400V

AC

(5)

(3)

2

SEC

2

GAS

2

DC

ASSY 19X1929 (460V)

GATE

DRIVE

2

ON/OFF SW

CHASSIS GND

1

CURRENT

CONTROL/

LED PCB

19X1604

W1

1

TEMP

W1

1

(1)

1

W1

(4)

PRI

(2)

CURRENT ADJUST:

20 - 80 FOR CM101

20 - 60 FOR CM81

IGBT

HEATSINK

TEMP

INDUCTOR

TEMP

J29

TS1

J14

P18

J18

FAN1

FAN2

M1

M2

J15P15

1

3

4

2

P11 J11

B

A

INPUT DIODE

ASSY 19X2073

IGBT BOARD

ASSY 19X1756

MAIN TRANSFORMER

J7B

J3B

J7A

J3A

P3B

P7B

P3A

P7A

E22

TEST

CONN

P24

W1

PS1

SOL1

GAS

SOLENOID

PRESSURE

SWITCH

MAIN

CONTACTOR

T5

PRI

SEC

P14 J27P27

J33 P33

P39

J39

ATC CONNECTION

CONFIGURATION

(STANDARD)

400V

3 PHASE

INPUT

GATE

DRIVE

GATE

DRIVE

GATE

DRIVE

11

22

11

22

21

22

23

POT LOW

GATE DRIVE B RTN

GATE DRIVE B

GATE DRIVE A RTN

GATE DRIVE A

- OUT SENSE

CURRENT SENSE

CURRENT SENSE RTN

TIP VOLTS

+12V

TORCH SW

PRESS GOOD

POT WIPER

RUN/SET

TIP SENSE

CSR

24

25

26

27

28

29

30

31

ISENSE

32

33

CURRENT SENSE RTN

34

35

36

CURRENT SENSE

OVERTEMP

OVTEMP

+12VDC

DC OK

4

5

3

6

7

12

9

15

10

14

16

13

19

20

17

18

11

8

1

2

POT HIGH

+12VDC

AC OK

DC COM

TORCH SW RTN

4

EXTENDER

5

3

6

7

12

9

15

10

14

16

13

19

20

17

18

11

8

1

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

4

5

3

6

12

9

15

10

14

16

13

19

20

17

18

11

8

1

2

4

5

3

6

7

12

9

15

10

14

16

D13

13

19

20

17

18

11

8

1

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

7

D33

ASSY 19X1913 - CM101

DC COM

W1 ON

D25

GAS ON

DC COM

DC COM

P13

J12 J43

P1

INV ON

DRAG ON

SW ON

ASSY 19X1775

LOGIC

ASSY 19X2284 - CM81

8

3

5

2

7

1

4

6

8

6

7

4

1

5

2

3

DC COM

TIP VOLTS

+12VDC

I SENSE

-OUT SENSE

CSR

TIP SENSE

(71)

(70)

(77)

(75)

(74)

(73)

(72)

8

3

5

2

7

1

4

6

8

6

7

1

4

5

2

3

PIP

3

5

2

1

4

66

1

4

5

2

3

8

TORCH SW

TORCH SW RTN

PIP

PIP RTN

2

TORCH

SW

(78)

(79)

(80)

(81)

J34

P34

1

4

3

J23

3

2

1

8

3

5

2

7

1

4

6

J24

8

6

7

1

4

5

2

3

(12)

(13)

(11)

(10)

(8)

(9)

J25

J30

J31

J26

1

2

1

2

1

2

1

22

P25

P30

P31

2

1

2

1

2

1

1

TS2

P32 J32

1

2

1

2

P29

NTC

1

2

3

4

1

4

2

3

(25)

(24)

28VAC B

SET

(21)

(22)

28VAC A

(23)

SW1

SW2

(26)

8

3

5

2

7

1

4

6

28VAC B

28VAC A

8

6

7

1

4

5

2

3

230V

(6)

(6)

(7)

230V

(7)

3

5

2

1

4

6

6

1

4

5

2

3

1

3

4

2

400V 'CE' VERSION

INCLUDES IN-LINE

EMC FILTER

IGBT BOARD

ASSY 19X1756

E12A

E17A

E19A

E21A

E9A

E11A

E12B

E17B

E19B

E21B

E9B

E11B

E52

E47

E3

E2

E1

E5

E13

E18

E6

E8

E14

E16

E15

E7

E4

E23

E20

E30

P26

E10

E27

E32

8

6

7

4

1

5

2

3

(36)

(38)

(37)

8

6

5

2

3

1

4

7

8

3

5

2

7

1

4

6

(35)

(41)

(40)

(39)

(42)

8

6

7

1

4

5

2

3

+12V

POT LOW

OVERTEMP

POT WIPER

POT HIGH

DC

GAS

AC

E5

E6

(FILTERING)

R29 (415/460/600V)

R78 (400V)

R30 (208/230V)

F1

T1

K2

K1

K1

28VAC A28VAC B

28VAC A

28VAC B

GND

SEE TABLE 1 FOR

F1, R29,R30 & R78

CLOSED WHEN

PRESSURE OK

TO BIAS SUPPLY

FAN

INRUSH

K1

K2

CONTACTOR ON

K5

SOLENOID ON

K4

K5

K4

F2, 0.9A,

(RESETABLE)

PRESS GOOD

8

2

1

4

3

ATC RECEIVER

ATC MALE

CONNECTOR

SENSE

CURRENT

MODE SW

RAR OFF

RUN

(46)

L1

L2

L3

E33

(PILOT PCB)

(F9)

(TS1)

(TS2)

ARC HOLD

E34

E36

E35

28VAC A

28VAC B

ARC HOLD

INPUT

/460V

3 PHASE

INPUT

1 PHASE

208/230V

MAIN BOARD

ASSY 19X1930 (400V)

ASSY 19X2228 (415V)

SOL2

BA

FACTORY INSTALLED OPTIONAL

TORCH MOUNTED GAS SOLENOID

5

7

5

7

PRI

SEC

11 15

6

10

T6

WHEN OPTIONAL TORCH MOUNTED GAS SOLENOID IS USED,

SOL1 IS POWERED BY T6 ONLY ,SOL2 POWERED BY P24-1,-2

ASSY 19X2285 - CM101

ASSY 19X1932 - CM81

24

12

23

1314

25

27

24567

1

28

24

12

23

1314

25

27

24567

1

28

tt

Art # A-07152

Loading...

Loading...