Introduction 2-1 Manual 0-4688

SECTION 2.0

INTRODUCTION

2.01 INTRODUCTION

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes elec-

trically conductive. The plasma arc cutting process uses

this plasma to transfer an electrical arc to the work-

piece. The metal to be cut is melted by the heat of the

arc and then blown away.

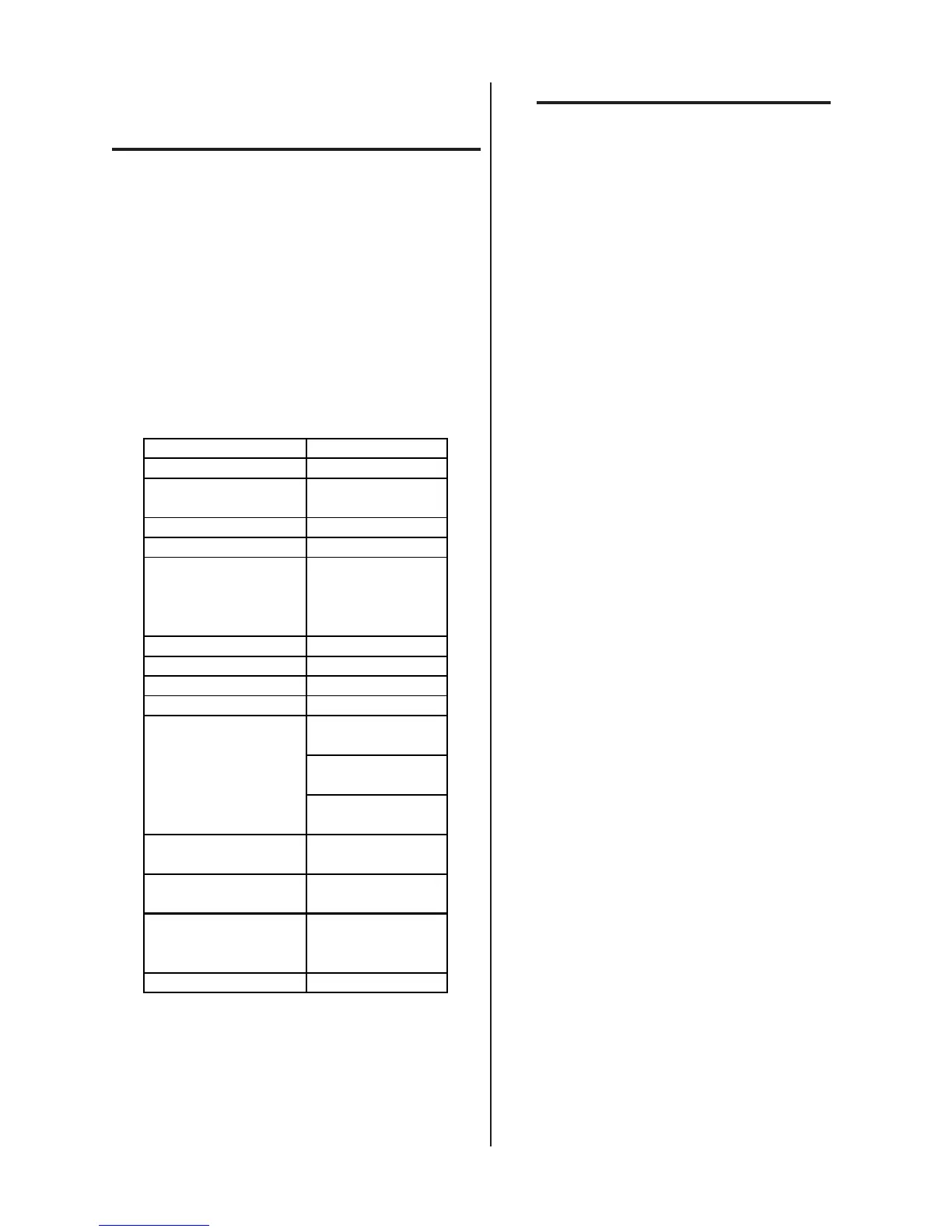

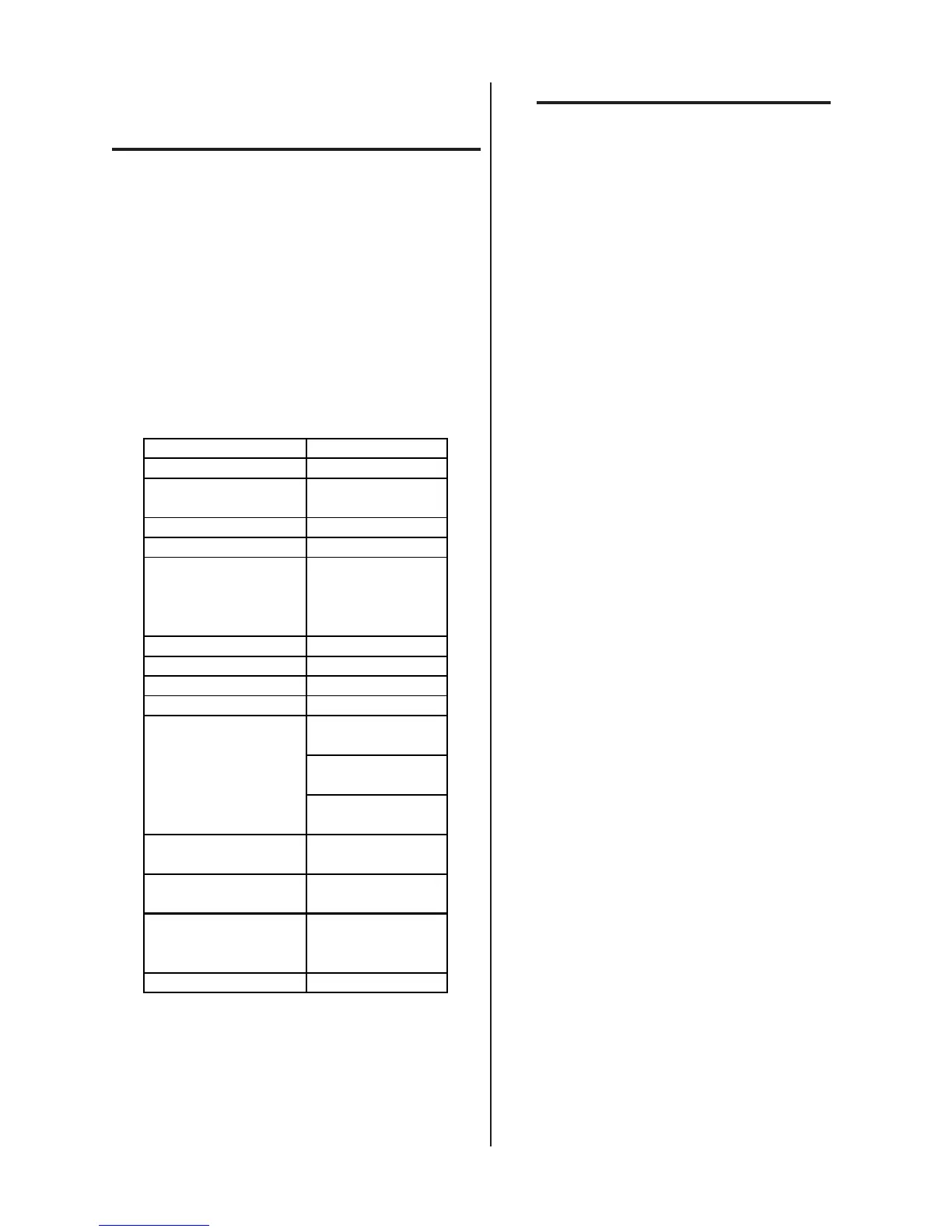

2.02 GENERAL SPECIFICATION

Input Voltage & Phase

Current Input fuse

U.S. / Canada 40

35% @ 35A @

60% @ 27A @

Genuine Cutting

3/8"

Maximum Cutting

5/8"

Dimension (W * D * H)

10.5"x15.5"x11"

(267 mm x 394 mm

x 279 mm )

Gross Weight 57 lbs. (26 kg

Duty cycle @ 104°F /

40° C Ambient

NOTE:

Refer to Local and National Codes or local au-

thority having jurisdiction for proper wiring re-

quirements.

2.03 Features

• COMPACT and LIGHT - Designed for easy trans-

portation.

• ENERGY EFFICIENCY - Advanced technology

reduces power consumption.

• HIGH SPEED GENUINE CUTTING - The con-

stricted plasma arc provides high speed cutting

as well as a good quality genuine, narrow cut.

• LOW COST WITH COMPRESSED AIR - The 35C

operates on compressed air.

• ALL KINDS OF METALS - Useful for most met-

als such as stainless steel, aluminum, mild steel,

copper and their alloys.

• PILOT ARC IGNITION FROM TORCH - The Pi-

lot Arc ignites the cutting arc.

• POWERFUL CUTTING PERFORMANCE -

Genuine cutting capacity is 3/8” (10 mm) and

5/8” (15 mm) for maximum cut.

• ABLE TO CUT PAINTED MATERIALS - Pilot Arc

ignition allows the 35C to cut painted materials.

• EXTENDED PARTS LIFE - Consumable parts life

is longer.

Loading...

Loading...