Operation 4-2 Manual 0-4688

4.02 Preparations For Operating

At the start of each operating session:

WARNING

Disconnect primary power at the source before

assembling or disassembling power supply, torch

parts, or torch and leads assemblies.

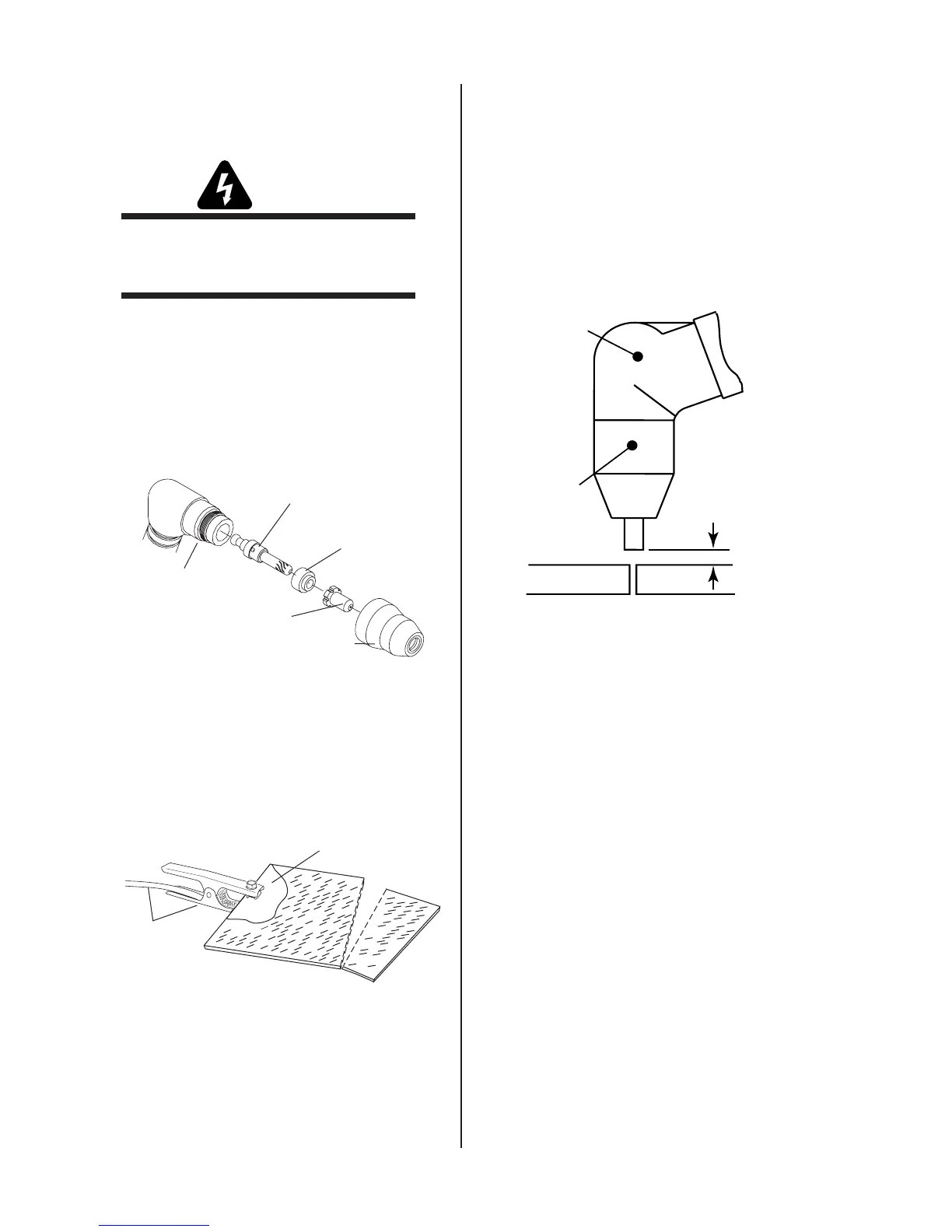

A. Torch Parts Selection

Check the torch for proper assembly and appro-

priate torch parts. The torch parts must correspond

with the type of operation, and with the amperage

output of this Power Supply (35 amps maximum).

Use only genuine manufacturer’s parts with this

torch.

Torch Head Assembly

Shield Cup, No. 9-6003

Gas Distributor,

No. 9-6507

Tip, No. 9-6501

Electrode, No. 9-6542

rt # A-04655

B. Torch Connection

Check that the torch is properly connected.

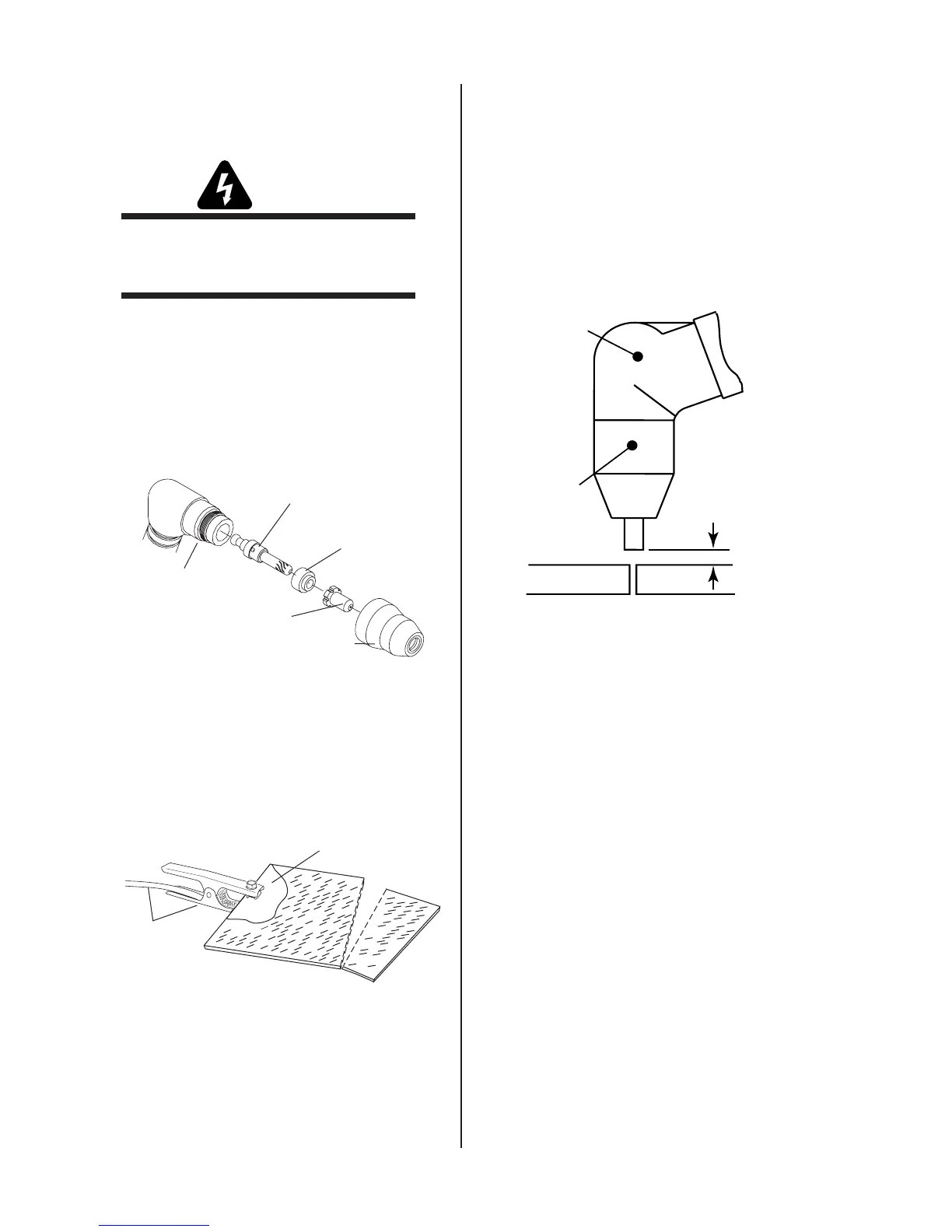

C. Connect Work Cable

connection to the work-

piece or cutting table

ork Cable

nd Clamp

D. Torch Operation

• Wear gloves and protective goggles.

• Do not place bare hand on work piece.

1. For drag cutting, keep the torch in contact with

the workpiece.

2. For standoff cutting, hold the torch 1/8 - 3/8

in (3-9 mm) from the workpiece as shown be-

low.

A-00024

hield Cup

Torch

Standoff

Distance 1/8" - 3/

3. With the torch in starting position, press and

hold the Torch Trigger. After an initial two sec-

ond pre-flow, the pilot arc will come on and

remain on until the cutting arc starts.

4. Once on, the cutting arc remains on as long as

the Torch Trigger is held down, unless the torch

is withdrawn from the work or torch motion is

too slow.

5. To shut off the torch simply release the Torch

Trigger. When the trigger is released a gas post-

flow will occur. If the Torch Trigger is pushed

during the post-flow, the cutting arc will restart

immediately when the torch is brought within

range of the workpiece.

Loading...

Loading...