DRAG-GUN Plasma Cutter 16 Operating Manual 0-2682

3. Start the pierce off the cutting line on the scrap piece

or template and then continue the cut onto the cut-

ting line. Hold the torch perpendicular to the

workpiece after the pierce is complete.

4. Clean spatter and scale from the shield cup and the tip

as soon as possible.

5.2 Cut Quality5.2 Cut Quality

5.2 Cut Quality5.2 Cut Quality

5.2 Cut Quality

Cut quality depends heavily on setup and parameters

such as torch alignment with the workpiece, cutting

speed, condition of torch parts, input line voltage, and

operator ability. Cut quality will also vary on different

types of material and thicknesses.

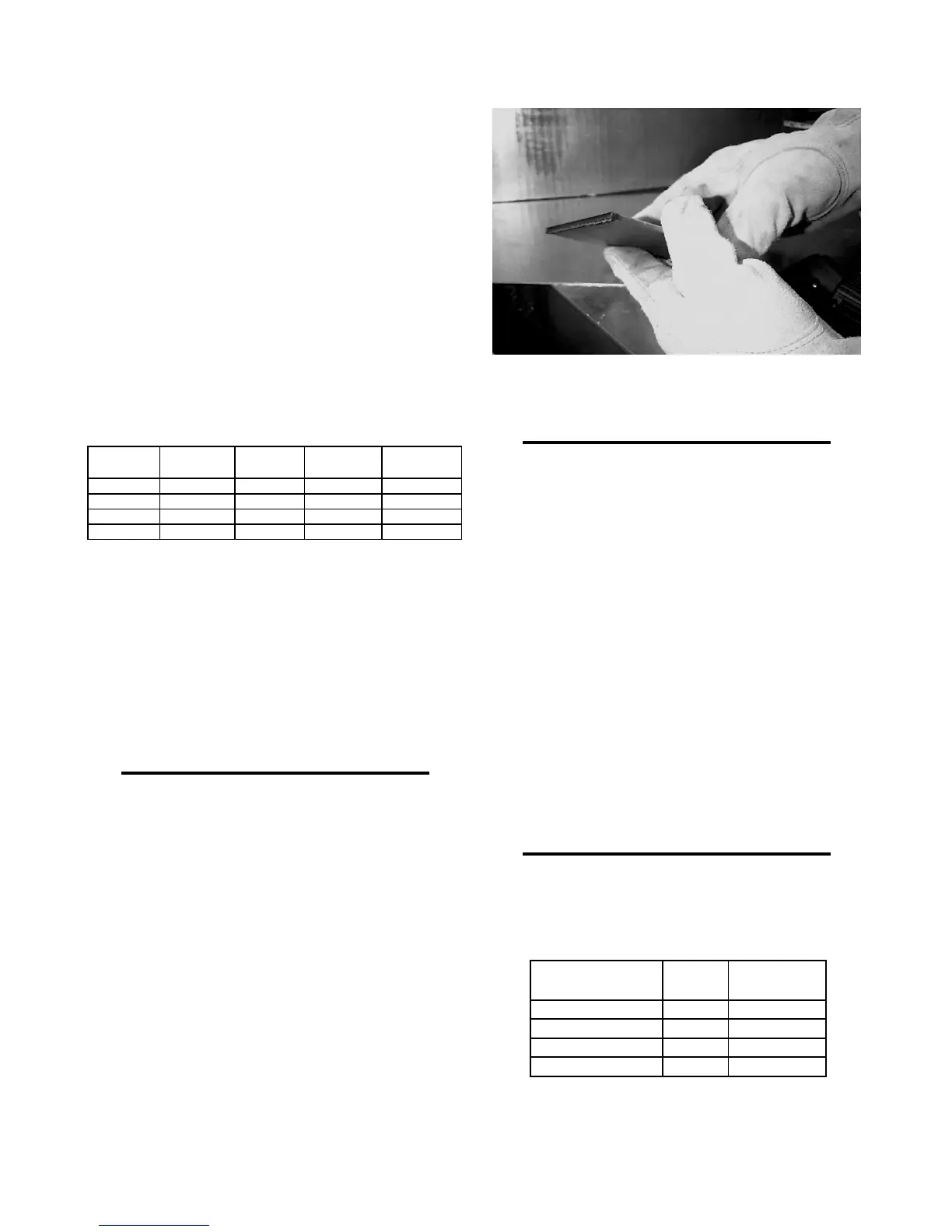

The following table shows the cut quality one can expect

from this equipment for materials with a thickness of

7 gauge or less:

Material

Thickness

Mild Steel Stainless

Steel

Aluminum Galvanized

Steel

20 Gauge Excellent Excellent Very Good Excellent

16 Gauge Very Good Excellent Good Excellent

10 Gauge Very Good Good NR Good

7 Gauge Severance Severance NR Severance

Figure 5-5 Cut Characteristics

Excellent - No bevel or dross*

Very Good -

Negligible bevel; slight dross* (easy to remove)

Good - Slight bevel with some dross* (easy to remove)

Severance - Substantial reduction in cut quality and speed

NR - Not Recommended

NOTES

Pierce Capacity is 1/16" (1.59 mm)

* Dross is molten material which is not blown out

of the cut area and resolidifies on the plate. Top

spatter is dross which accumulates on the top sur-

face of the workpiece. Top spatter is normally

caused by a slow torch travel speed or too high of a

torch standoff distance. Dross normally breaks off

quite easily by simply scraping it off with a piece

of metal.

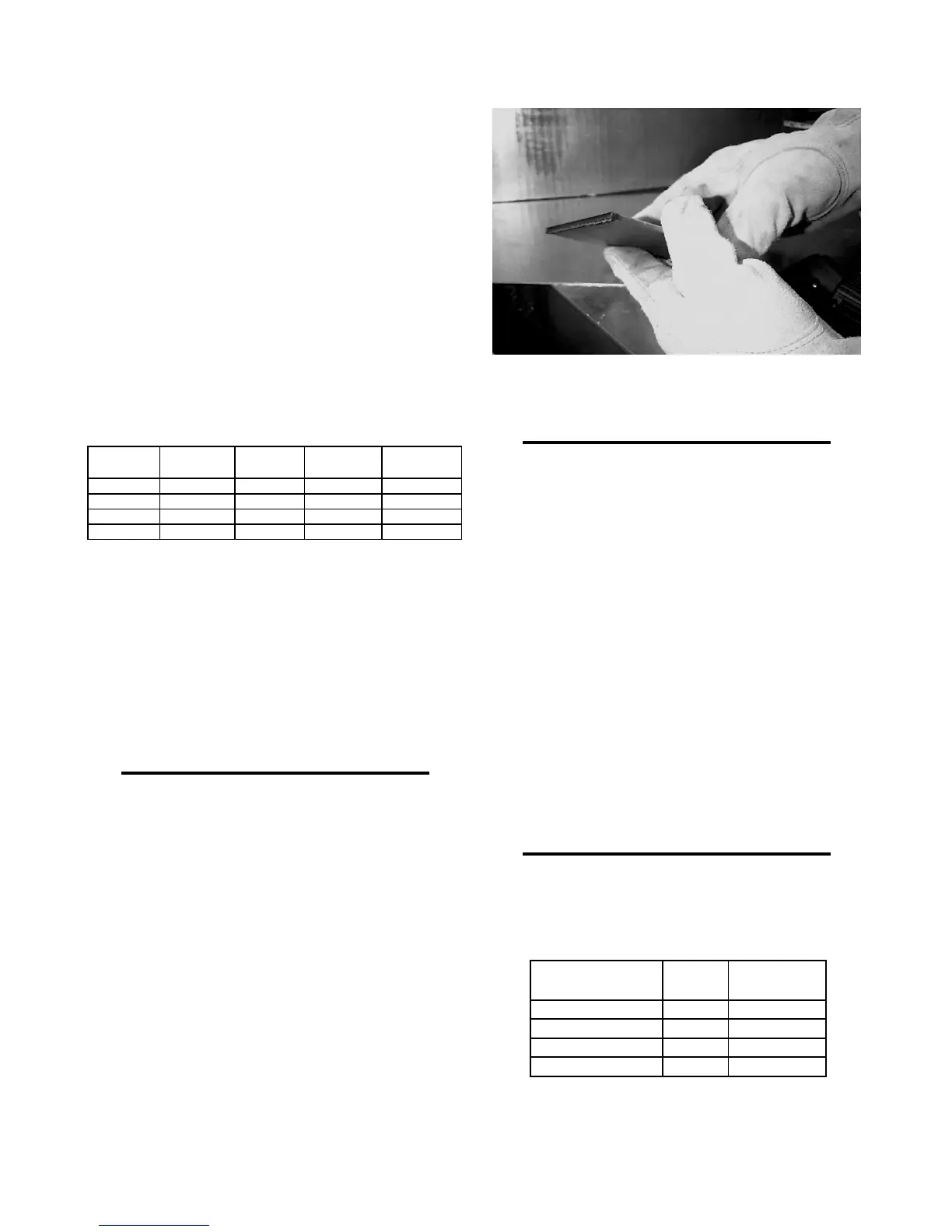

Figure 5-6 Cut Sample

NOTE

A worn tip can also affect the quality of a cut.

Consider replacing the tip if any of the following

indicators are present:

• reduced speed

• voltage drop

• crooked cut

5.3 Recommended Cutting5.3 Recommended Cutting

5.3 Recommended Cutting5.3 Recommended Cutting

5.3 Recommended Cutting

SpeedsSpeeds

SpeedsSpeeds

Speeds

Cutting speed depends on material type, material thick-

ness, and the operator’s ability to accurately follow the

desired cut line. The following factors may have an im-

pact on system performance:

• Torch parts wear

• Line voltage fluctuations

• Torch standoff height

NOTE

This information represents realistic expectations

using recommended practices and well-maintained

systems. Actual speeds may vary up to 50% from

those shown.

Material Gauge Inches per

Minute

Stainless Steel 20 60

Galvanized Steel 18 60

Aluminum 16 20

Carbon Steel 10 9

Figure 5-7 Cutting Speed Chart

Loading...

Loading...