January 8, 2009 3 Manual 0-2880 Rev AB

Spare Parts Label

The parts kit provided with the torch includes an adhe-

sive label. Select the small perforated section showing the

appropriate pressure setting for the amperage output and

leads length to be used with this torch. Refer to the charts.

Apply this section in the 'Gas Supply' area of the label

under the 'Recommended Operating Pressure' text. Dis-

card any pressure setting sections of the label that will not

be used. Apply the large label to the power supply, where

the operator can see it for easy reference.

Torch Parts Selection

Refer to the Consumables Selection Chart for the various torch

parts for the application and operation.

WARNINGS

Disconnect primary power to the system before dis-

assembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

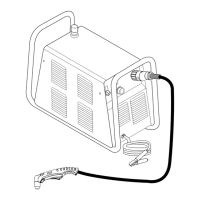

The shield cup (or shield cup body and shield cap or deflector)

holds the tip and starter cartridge in place. Position the torch

with the shield cup facing upward to keep these parts from

falling out when the cup is removed.

Change the torch parts as follows:

1. Unscrew and remove the shield cup from the torch

head.

Art # A-03417

Electrode

Start Cartridge

Tip

Shield Cup

Assembly

Torch Head

2. Tilt the torch head to remove the tip and starter car-

tridge.

3. Fit the desired starter cartridge and tip onto the electrode.

NOTE

Refer to the consumables selection chart for the proper

combination of torch parts, including shield cups

and caps.

4. Hand tighten the shield cup until it is seated on the torch

head. Do not use tools to tighten the cup. If resistance is

felt when installing the cup, check the threads before pro-

ceeding.

NOTE

When operating the torch in a normal condition,

a small amount of gas vents through the gap be-

tween the shield cup and the torch handle. Do not

attempt to overtighten the shield cup as irrepa-

rable damage to internal components may result.

Gouging Parts Selection

Select gouging tips according to the desired gouge profile.

Gouging parameters shown are based on a 35° approach angle.

Output Range Depth Width

Tip A 40 Amps Max. Shallow Narrow

Tip B 40-100 Amps Deep Narrow

Tip C 40-100 Amps Moderate Moderate

Tip D 40-100 Amps Shallow Wide

Gouging Profiles

Operating Gas Pressure

Set gas pressure at the power supply regulator according to the

following charts. These charts are a guide only; adjust as nec-

essary for best performance.

Tip

20' / 6.1 m 50' / 15.2 m

30A, 40A,

50/55A, 60A

65 psi / 4.5 bar 75 psi / 5.2 bar

Leads Length

SL60 Gas Pressure Settings

Tip

Up to 25' / 7.6 m 50' / 15.2 m

30A, 40A,

50/55A, 60A,

70A, 80A

60 psi / 4.1 bar 65 psi / 4.5 bar

90/100A 65 psi / 4.5 bar 70 psi / 5.2 bar

SL100 Gas Pressure Settings

Leads Length

Loading...

Loading...