Page 23 of 29 Revision 3.3 Feb 2021

ProReact EN Analogue Installation Manual

Document Ref. PACC-MAN

Alarm Conditions

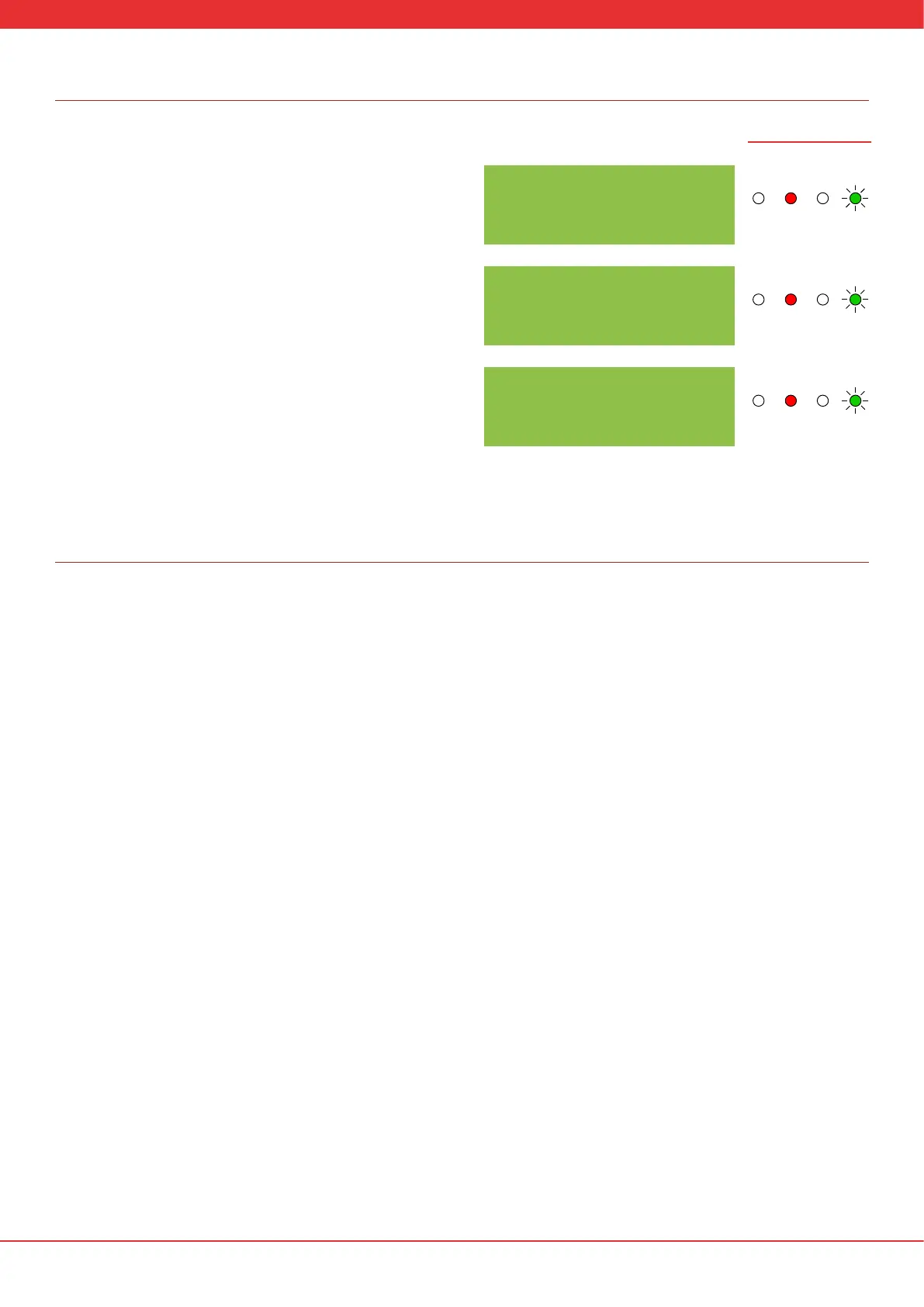

24. If the current measured resistance of the sensor cable (“Curr”) drops

below the alarm threshold (as shown on the display right), the control

unit will trigger an alarm. (Note: the pre-alarm threshold is not shown on

the built-in display. The laptop/PC software must be used to determine

this value). The alarm output will be set and the alarm LED will illuminate

25. If the rate-of-change of the resistance of the cable exceeds a preset

value (equal to when approximately 2% of the cable is heated at greater

than 15°C/min for at least 3 minutes), a rate alarm may be triggered. The

alarm output will be set, the alarm LED will illuminate and the display will

show “Rate Alarm”.

26. If the measured average ambient temperature of whole sensor cable

exceeds the alarm temperature for the chosen alarm setting, the control

unit will trigger an alarm. For example, in this case the measured ambient

temperature is 63.4°C which is above the alarm temperature for the

whole cable on alarm setting Class A1I/A2I. The alarm output will be set

and the alarm LED will illuminate.

CU R R: 2 5M Ω

1 3.4

O

C A: 45MΩ

CURR: 100MΩ

6 3.4

O

C A: 45MΩ

CU R R: 4 5 MΩ

1 3.4

O

C RATE ALARM

LED Illustrations

Alarm Fault Power

Pre

Alarm

Alarm Fault Power

Pre

Alarm

Alarm Fault Power

Alarm Fault Power

Pre

Alarm

Alarm Fault Power

Pre

Alarm

Alarm Fault Power

Alarm Fault Power

Pre

Alarm

Alarm Fault Power

Pre

Alarm

Alarm Fault Power

Resetting the control unit after an alarm condition

Following an alarm condition the alarm (or pre-alarm) output will

latch (remain set) until the control unit is reset. Providing none of the

conditions listed in steps 24-26 remain, there are several methods to reset

the alarm condition:

1. Press the SET button on the control unit for >3s to clear the alarm

condition.

2. Provide 5-28Vdc to the Remote Reset input for >3s (see “Control

Module Wiring”).

3. Send a “Write Single Coil (0x05)” command to coil address 0 via the

Modbus RS-485 connection.

4. Interrupt power to the control unit for at least 3s.

Loading...

Loading...