Page 7 of 29 Revision 3.3 Feb 2021

ProReact EN Analogue Installation Manual

Document Ref. PACC-MAN

Theory of Operation

The ProReact EN Analogue LHD system uses a heat sensitive cable to

monitor an area, critical equipment or the like, for an overheat or re

condition.

The ProReact EN Analogue Composite Control Unit continuously

monitors the resistance of temperature sensitive polymers within the

ProReact EN Analogue LHD cable. The resistance of the ProReact EN

Analogue LHD cable decreases as the temperature around the cable

increases. An abnormal change in resistance, due to an overheat

condition, along the cable triggers either a Pre-Alarm or Alarm on

the ProReact EN Analogue Composite Control Unit. The ProReact EN

Analogue Composite Control Unit can be interfaced to a conventional or

addressable re alarm system.

For the alarm temperature to be stable across a range of ambient

temperatures, the ProReact EN Analogue Composite Control Unit

measures the average ambient temperature across the entire cable and

dynamically adjusts the alarm threshold accordingly.

It is important therefore to ensure that the ProReact EN Analogue

Composite Control Unit is set up correctly and the cable resistance and

the average ambient temperature as shown on the ProReact EN Analogue

Composite Control Unit are as expected. See the Commissioning section

for more information about setting up a ProReact EN Analogue LHD

system.

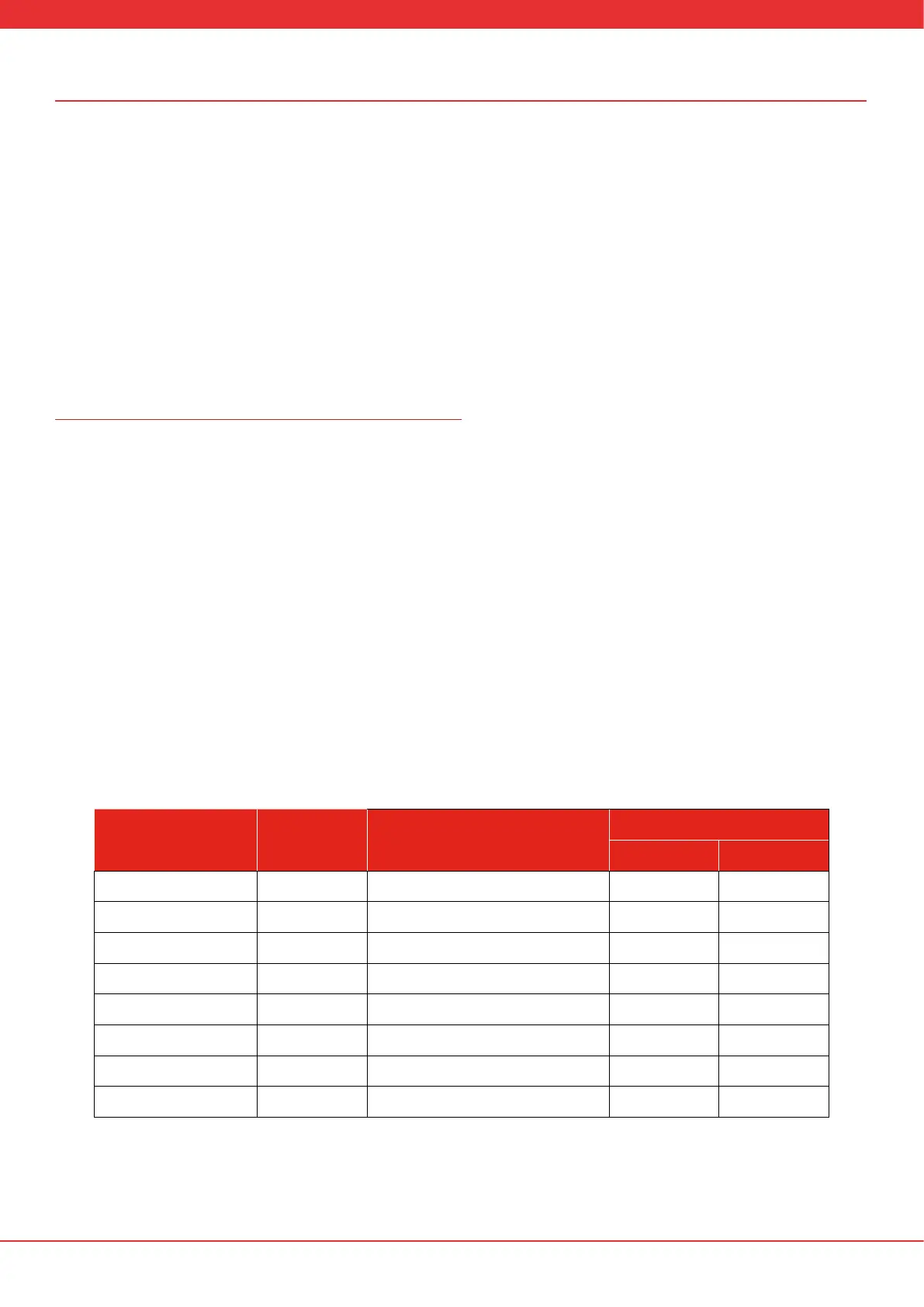

Alarm Temperatures

The ProReact EN Analogue LHD system is designed so that an alarm will

be triggered when the temperature around a section of ProReact EN

Analogue LHD cable (equal to 3% of its total length) reaches a nominal

alarm temperature predetermined by the chosen setting on the ProReact

Composite Control Unit (as shown in Table 1).

The actual exposure temperature required to trigger an alarm will

be lower than the nominal alarm temperature (as shown in Table 1)

if a larger section of ProReact EN Analogue LHD cable is exposed

to an abnormal rise in temperature. Likewise, the actual exposure

temperature will be higher that the nominal alarm temperature

if a shorter section of ProReact EN Analogue LHD cable is exposed

to an abnormal rise in temperature.

When the sensor cable is installed and operated in hotter environments,

the sensor cable may need to be exposed to a higher temperature than

that required in a cooler environment in order to trigger an alarm for a

given setting on the ProReact EN Analogue Composite Control Unit. In

such circumstances, the ProReact EN Analogue Composite Control Unit

dynamically adjusts the alarm threshold to reduce the likelihood of false

alarms.

Refer to the “Application Temperatures” section for more information on the

typical and maximum application temperature for each controller setting.

Please refer to the charts on the following page for illustrative examples

of the expected temperature a given portion of Analogue LHD cable

must be exposed to in order to trigger an alarm by ProReact Composite

Control Unit setting.

Rate-of-rise activation

Note: for the Class A1I/A2I, 54°C and 64°C Alarm settings the control

unit will also trigger an alarm if approximately 2% of the sensor cable is

heated at more than 15°C per minute for longer than 3 minutes. This will

show as a rate alarm (see step 25 in the commissioning procedure).

VdS EN54-22:2015

+A1:2020 Approved

UL listed

(UQGS)

Available Controller Setting

Nominal Alarm Temperature

°C °F

3 ✗

Class A1I/A2I 66 151

3 ✗

Class BI 80 176

✗ 3

54 54 129

✗ 3

64 64 147

✗ 3

72 72 162

✗ 3

79 79 174

✗ 3

86 86 187

✗ 3

100 100 212

Table 1 - ProReact EN Analogue Composite Control Unit settings & nominal alarm temperatures in typical

application temperatures (based on 3% of total cable length)

Loading...

Loading...