40

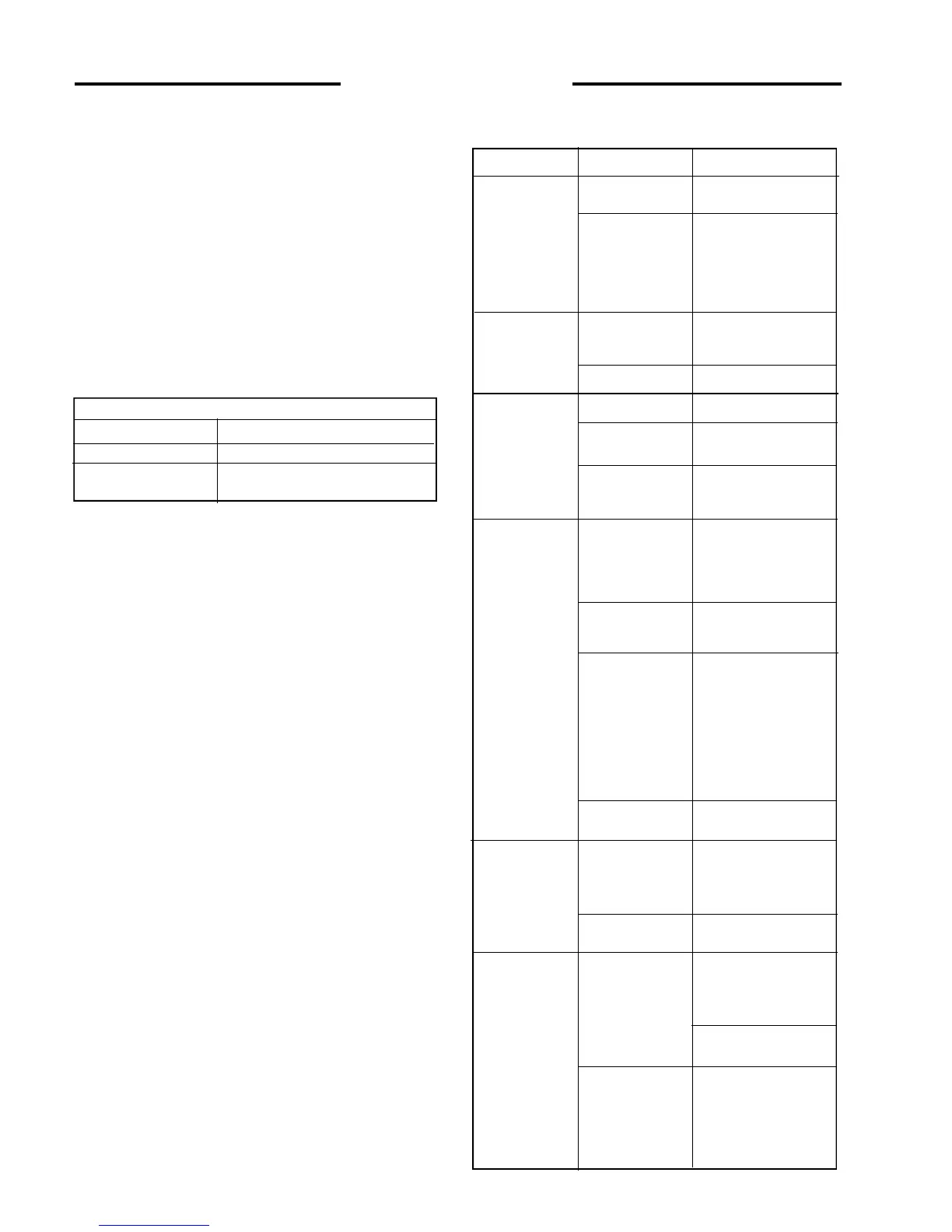

Problem Cause Remedy

• Do not weld, braze, otherwise repair, or use a damaged

rim.

• Never attempt tire repairs on a public road or highway.

• Use jack stands or other suitable blocking to support the

loader while repairing tires.

• Insure jack has adequate capacity to lift your loader.

• Insure jack is placed on a firm level surface.

Do not put any part of your body under the loader or

start the engine while the loader is on the jack.

• Torque lug nuts to specification after reinstalling wheel.

Check lug not torque daily until torque stabilizes.

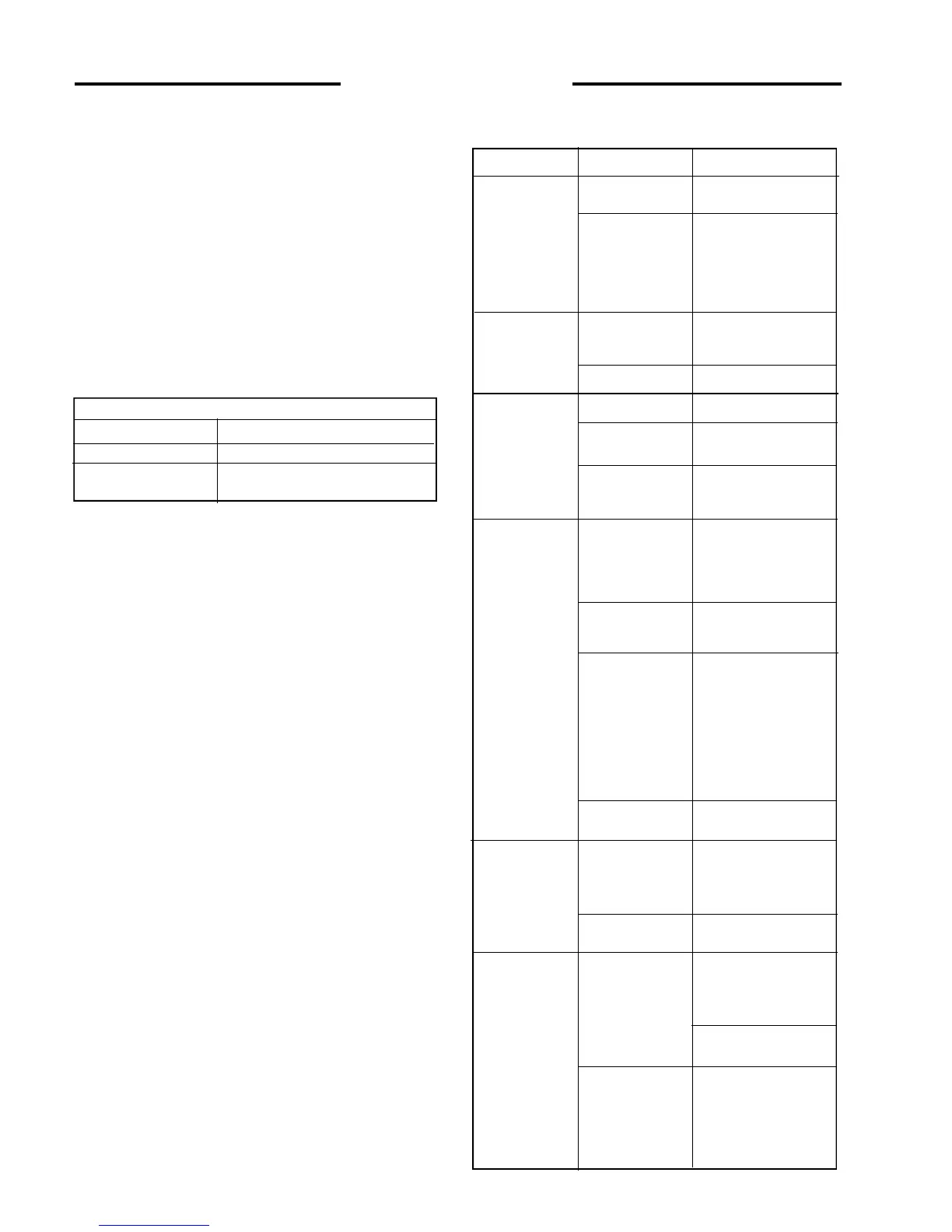

Tire Inflation Table:

Tire Inflation Pressure

7.00 x 15 50 PSI (345 kPa)

10.00 x 16.5 40 - 45 PSI (276 - 310 kPa)

4. 10B Tire Rotation

The front and rear tires will wear at different rates. For

even wear move the front tires to the rear and the rear tires

to the front when wear is first noticed.

If two tires become worn more than the other two put the

two worn tires on the same side.

When new tires are installed, always keep tires the same

size on the same side of the loader. Two different size tires

on the same side of the loader will cause drive chain wear,

tire wear and a loss of power.

4.11 TROUBLE SHOOTING

4. 11A Electrical System

This machine is equipped with a 12 Volt negative ground

electrical system. The charging system is equipped with

an alternator and built in regulator. The starting circuit is

equipped with a starter motor, glow plugs, and solenoid for

starting the engine.

The seat belt and seat switch are wired in series. In order

to operate the loader, the operator must be sitting in the

seat with the seat belt securely fastened around the waist.

Check battery, charge

or replace

Check for loose or

corroded connectors.

Tighten and clean as

required. Use di-

electric grease to

prevent corrosion.

Check continuity of

cables and replace if

defective

Repair or replace

Check and replace

Check relay continuity

if defective, replace

Check continuity,

repair or replace

Engine will smoke, but

not run unassisted by

starter Disengage

auxiliary hydraulics

See Sect. 2.8 - 2.10.

Check continuity and if

defective replace

Disconnect the ROPS

harness from the

engine harness Fig.

4.10A. Open the dash

panel and check

continuity of the circuit

not functioning

properly in both engine

and ROPS harness

Check fuel level

Defective solenoid or

binding solenoid lock.

Loosen screws and

readjust

Check continuity of

connectors and wire

Defective solenoid or

binding solenoid lock.

Loosen screws and

readjust

Check continuity of

connectors and wire

Check and replace if if

necessary

Battery failure

Battery cable failure

Starter failure

Fuse burnt

Defective relay

Ignition switch

failure

Auxiliary hydraulics

engaged

Defective glow plug

relay

Broken connection

or defective wire

No fuel

Electro solenoids not

releasing valve

spools

Broken or poor

contact from relay to

solenoid on valve

Poor connection in

harness

Engine will not

crank over

Engine cranks

over, will not start

Loader starts, but

foot controls will

not release

Engine will not

stop when the key

is turned OFF

4 MAINTENANCE

Contact Thomas Equipment for all major fixes under the

remedy column except for regular service (i.e. Replenish

fluids, tightening etc.).

Loading...

Loading...