33

4. MAINTENANCE

4.3 DAILY SERVICE

4.3C Hydraulic System

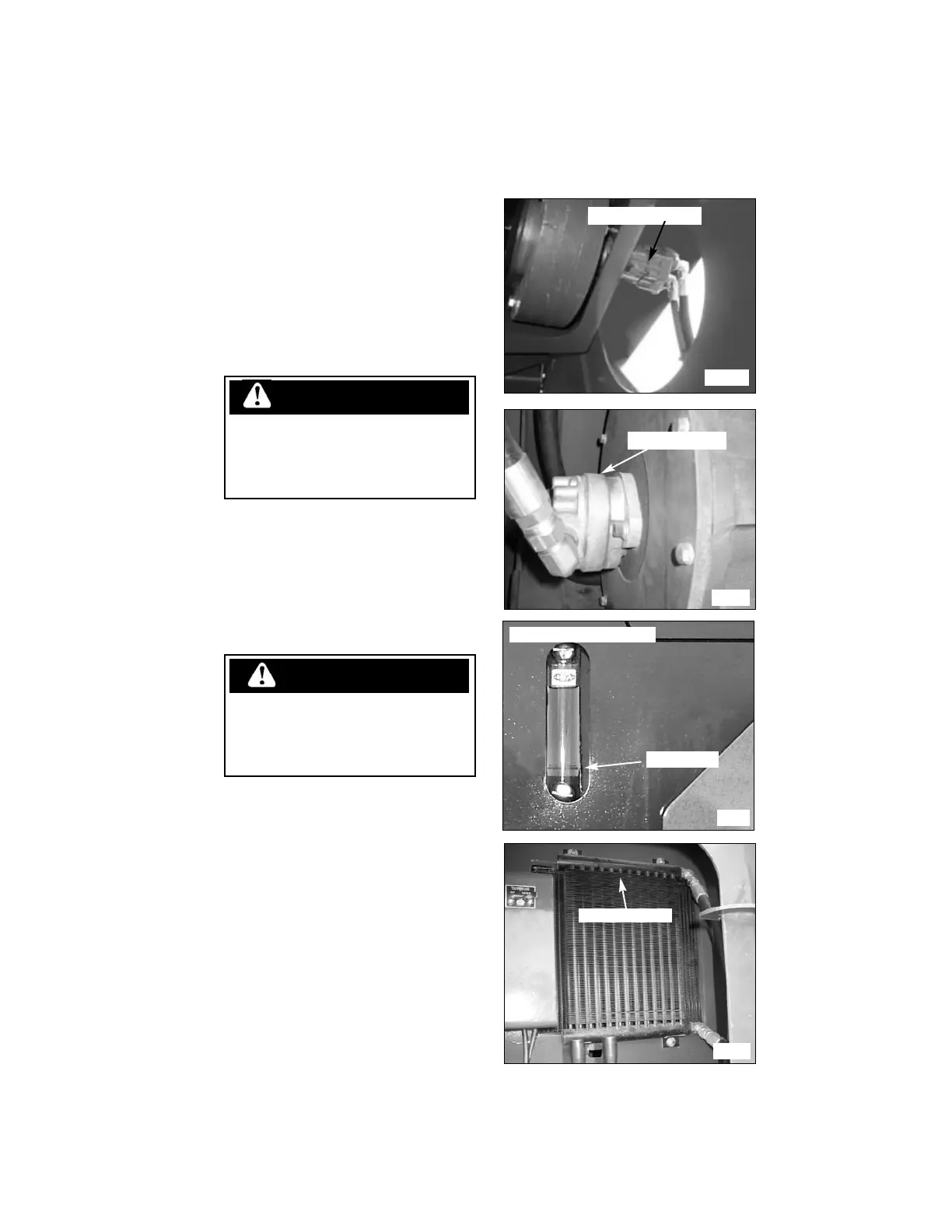

Check hydraulic hoses, pumps and

motors for leaks (T90012, T90102). Check

each hydraulic hose for chafing or bulging.

Replace immediately as required.

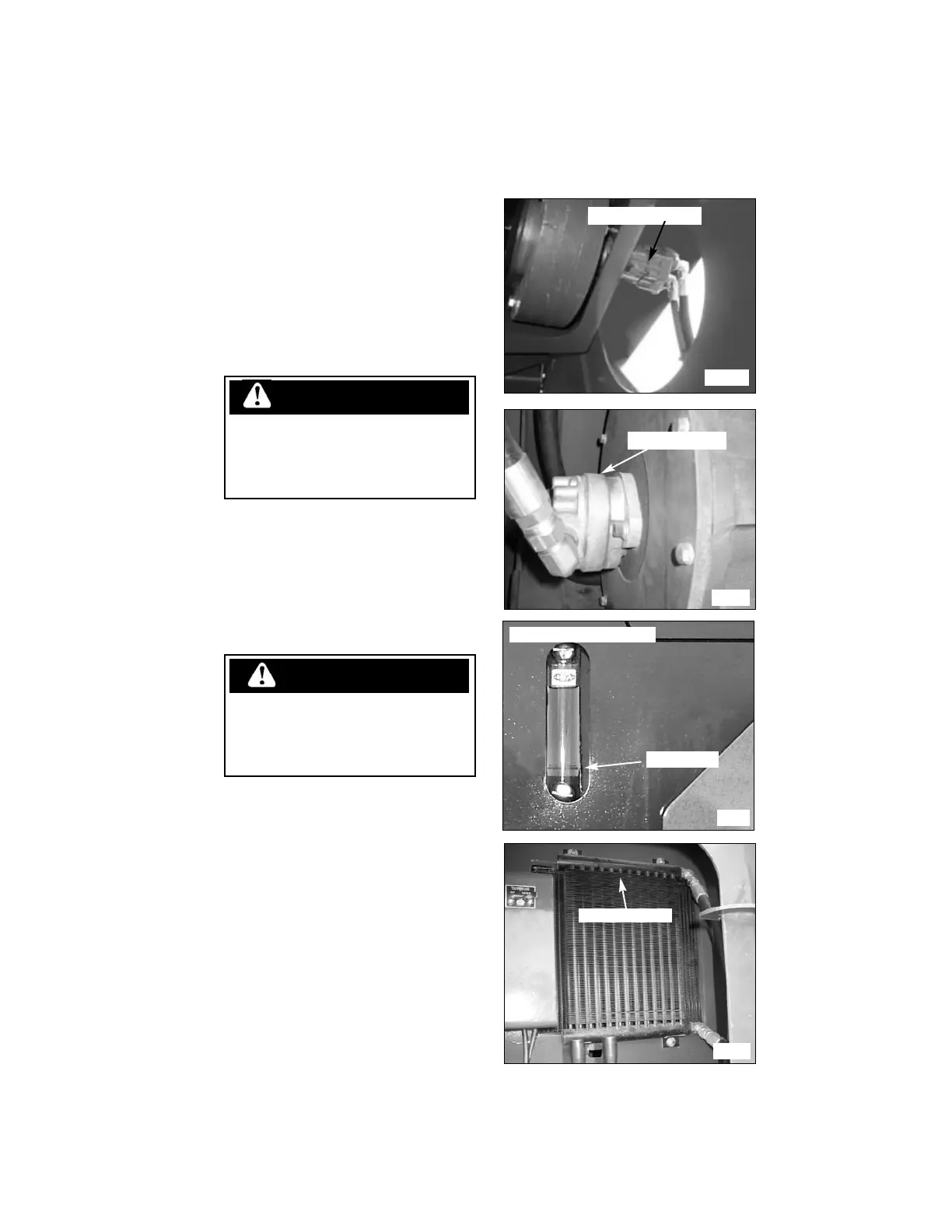

Check the hydraulic fluid level (S0055).

Fill to the upper level on site gauge with

10W30, minimum API classification CF

motor oil.

Check the hydraulic oil cooler fins for

obstructions (T90097). Clean with com-

pressed air and or flush with water.

4.3 DAILY SERVICE

4.3D Safety Equipment

Ensure all safety, warning and instruc-

tion decals are in place and legible. See

section 1.2 for decal placements.

Ensure all shields are in place.

Make sure all compartment doors are

closed and secured before operating.

Make sure all lighting is in working

order.

Do not exceed 40 PSI (276 kPa) when

servicing the radiator and oil cooler. Wear

safety glasses when using compressed air.

WARNING

Never repair or tighten hydraulic hoses or

fittings while the machine is running. Fluid

under pressure can penetrate the skin and

cause serious injury.

WARNING

S0055

Hydraulic oil level site gauge

Minimum level

T90097

Hydraulic oil cooler

T90102

Hydraulic gear pump

Hydraulic Shaker motor

T90012

Loading...

Loading...