34

4. MAINTENANCE

4.3 DAILY SERVICE

4.3E Lubrication

There are six (6) lubrication points on

this machine that require regular service.

Use a high quality lithium based grease.

For grease fittings, apply two (2) shots per

fitting, for inner tubes, lubricate with

enough grease to ensure proper movement.

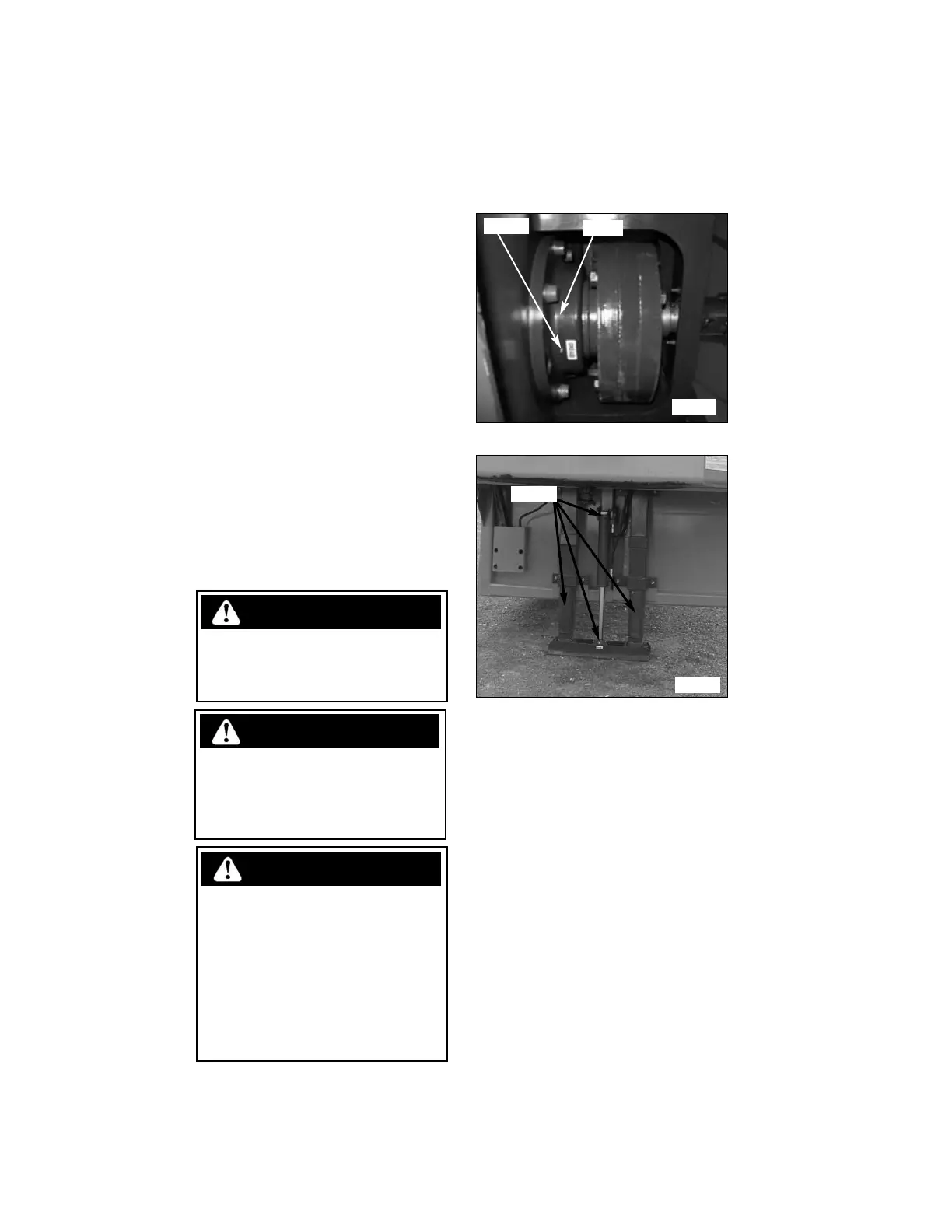

The two (2) shaker drive shaft bearings

require weekly lubrication, or every seven-

ty two (72) hours of operation, whichever

comes first (Refer to T90022). Apply 15

shots of Mobile SHC 220 (or equivalent)

per grease fitting.

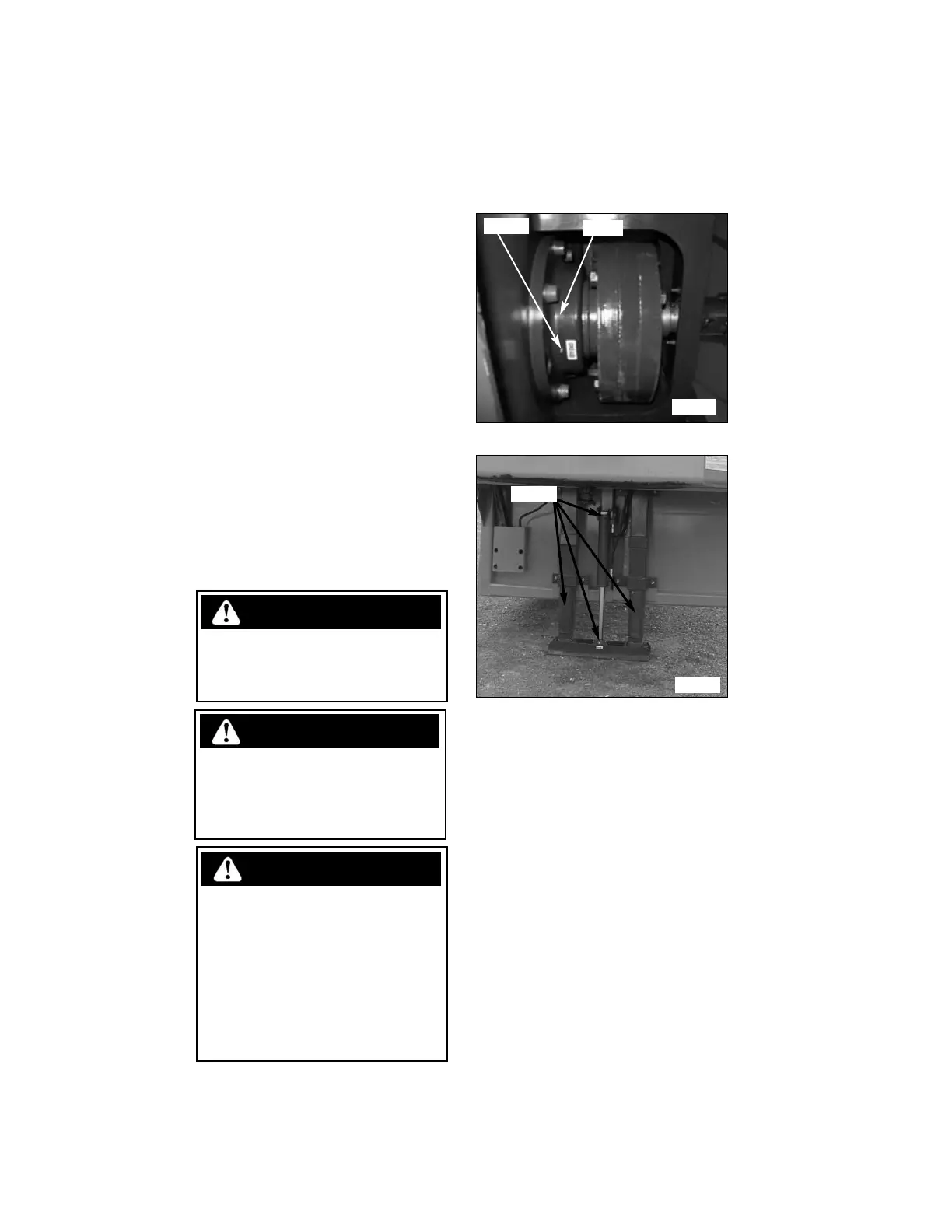

The front hydraulic lift cylinder has two

(2) grease fittings and two (2) inner tubes

that require lubrication. Grease each one

before transporting the machine to a new

location (Refer to T90115).

When performing maintenance, ensure the

engine is off and the ignition key is

removed to prevent accidental start up.

WARNING

To prevent personal injury DO NOT

charge a frozen battery because it can

explode. Let the battery warm to 60°F

(15.5°C) before putting on a charger.

WARNING

T90022

T90115

Lubricate

Bearing

Lead-acid batteries contain sulfuric acid

which will damage the eyes or skin on

contact. Always wear goggles to avoid

acid in the eyes. If acid contacts the eyes,

wash immediately with LARGE

QUANTITIES of clean water and get

medical attention. Wear rubber gloves and

protective clothing to keep acid off the

skin. If acid contacts the skin, wash off

immediately with clean water.

WARNING

Lubricate

Loading...

Loading...