-28-

Main Rotor Blade Assembly /

主旋翼組裝

Bag KP1

HMC3-20B

SOCKET SCREW M3×20

內六角螺絲

M3×20

HMM3Z

M3 NYLON NUT

M3

防鬆螺帽

No.

1

2

3

Qty

2

2

2

Material No.

BK1442

HMC3-20B

HMM3Z

Description

BLADE SPACER

SOCKET SCREW M3×20

M3 NYLON NUT

名稱

主旋翼墊片

內六角螺絲

M3×20

M3

防鬆螺帽

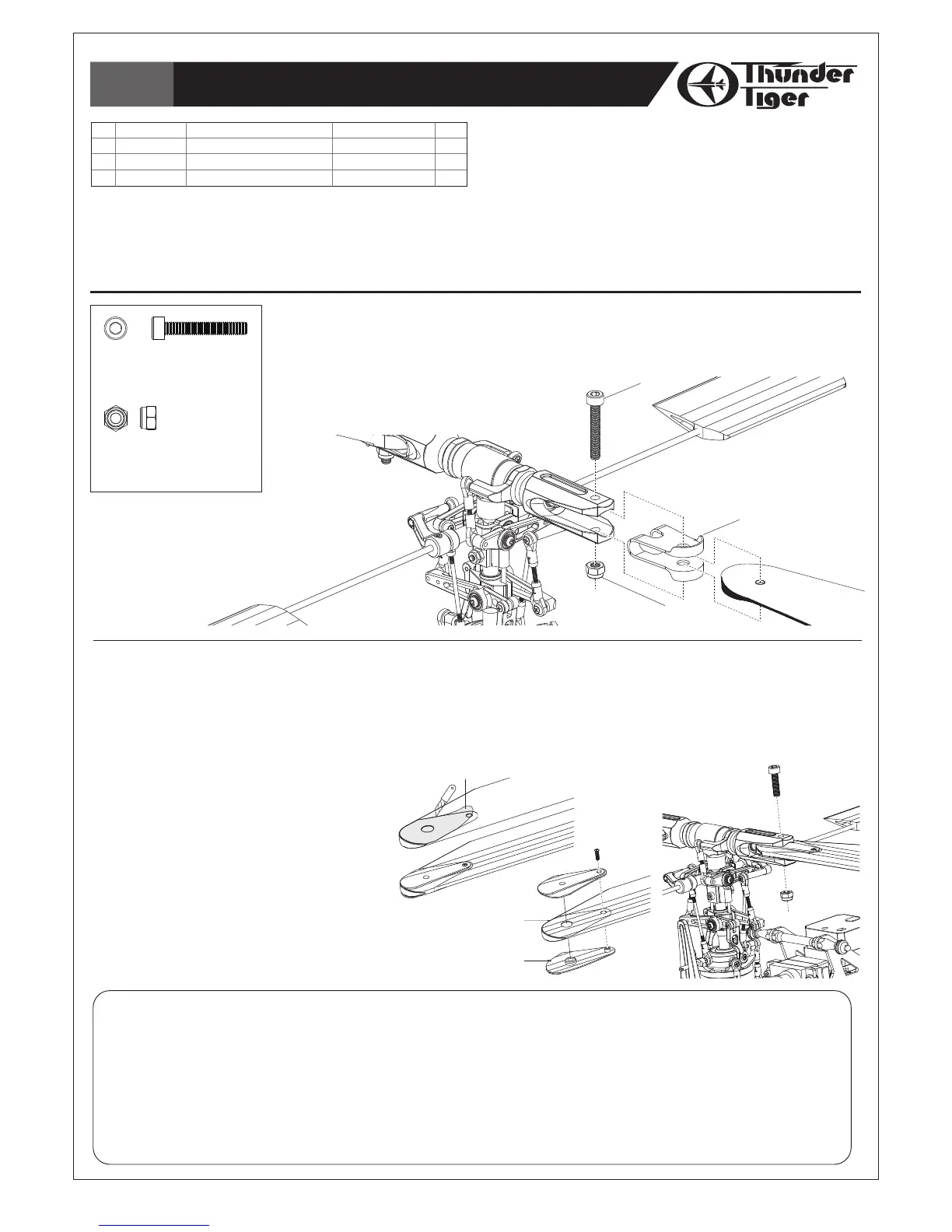

For Wood Blades:

For safety concern, ensure the wood blades are assembled as per the following:

1. Mark around the blade grips with a felt tip marker.

2.

Remove the blade grips and cut the covering gently around 1mm inside of the mark. Be careful not to damage the blades.

3. Sand the inside of the grips lightly for better adhesion. Apply CA or Epoxy to blades in area as shown.

4. Attach blade grips and tighten the screws.

5. Wipe off the excess CA or Epoxy.

6. Calibrate and balance the weight before using.

For Fiber-glass(FRP) or Carbon Blades:

1. Remember to attach the Blade Spacer on the grips as drawing.

2. Install the main blades with the Socket Screw (HMC3-20B, #3). Do not over tighten and

ensure the blades run effortlessly.

使用玻纖或碳纖維主旋翼時:

1. 請記得加上主旋翼墊片。

2. 以內六角螺絲安裝上主旋翼。請勿過度鎖緊。

(2)

(1)

(3)

木槳主旋翼組裝:

安全起見,請確實依下列程序組裝主旋翼木槳:

1. 將主旋翼連接座與旋翼進行假安裝,並於旋翼包

膜上描繪連接座形狀。

2. 移開連接座,以刀片依連接座形狀小心地切除包

膜,請注意勿切割到旋翼本體。

3. 可將連接座內側稍以砂紙打磨,以增加黏著力。

將去除包膜的旋翼部份平均塗上快乾膠,如下圖

所示。

4. 將旋翼連接座合入旋翼本體,並確實鎖好螺絲。

5. 去除多餘滲出的膠水,即完成。

6. 進行配重及平衡。

CA Glue or Epoxy

快乾或環氧樹脂

CA Glue or Epoxy

快乾或環氧樹脂

Note / 注意

1. You may need to adjust the linkage to ensure the blade tracking. Please refer page 39 “Blade Traking

Adjustment”.

2. For safety, we strongly suggest using wood or FRP blades for level flight only, rpm should not exceed 1500.

Upgrading to carbon blades for F3C or 3D flying is strongly recommended.

3. For safety the rpm of using carbon blades should not exceed 3200.

1. 您可能必需調整相關的連桿來確保旋翼旋轉軌跡正常。請參閱第39頁“主旋翼軌跡調整”說明。

2. 安全起見,在飛行F3C科目或3D動作時,我們強烈建議您將主旋翼換裝碳纖維槳;木槳或玻纖槳僅適合旋翼轉速不超過

1500rpm的一般飛行使用。

3. 安全起見,碳纖維主旋翼轉速請勿超過3200rpm。

Remove the membrane along the grips.

移除該部份包膜

Loading...

Loading...