Titan Implement, LLC 33 1200-1600 Series Rotary Cutters

(423) 334-0012 August 2016

Note: The rotary cutter will not operate on tractors

equipped with a 1000 RPM 21-spline or 1000

RPM 20-spline, 1-3/4” shaft.

Refer to the tractor owner’s manual for instructions to

change PTO speeds on models that operate at more

than one speed.

If operating an older model tractor where the tractor’s

transmission and PTO utilize one master clutch,

an over-running clutch must be used between the

PTO output shaft and the driveline of the mower. An

authorized tractor dealer can provide the over-running

clutch and its installation, if needed.

DO NOT use a PTO adapter to attach a non-matching

implement driveline to a tractor PTO. Use of an adapter

can double the operating speed of the implement,

resulting in excessive vibration, thrown objects, and

blade and implement failure. Adapter use will also

change the working length of the driveline exposing

unshielded driveline areas. Serious bodily injury and/or

equipment failure can result from using a PTO adapter.

Consult an authorized dealer for assistance if the

implement driveline does not match the Tractor PTO.

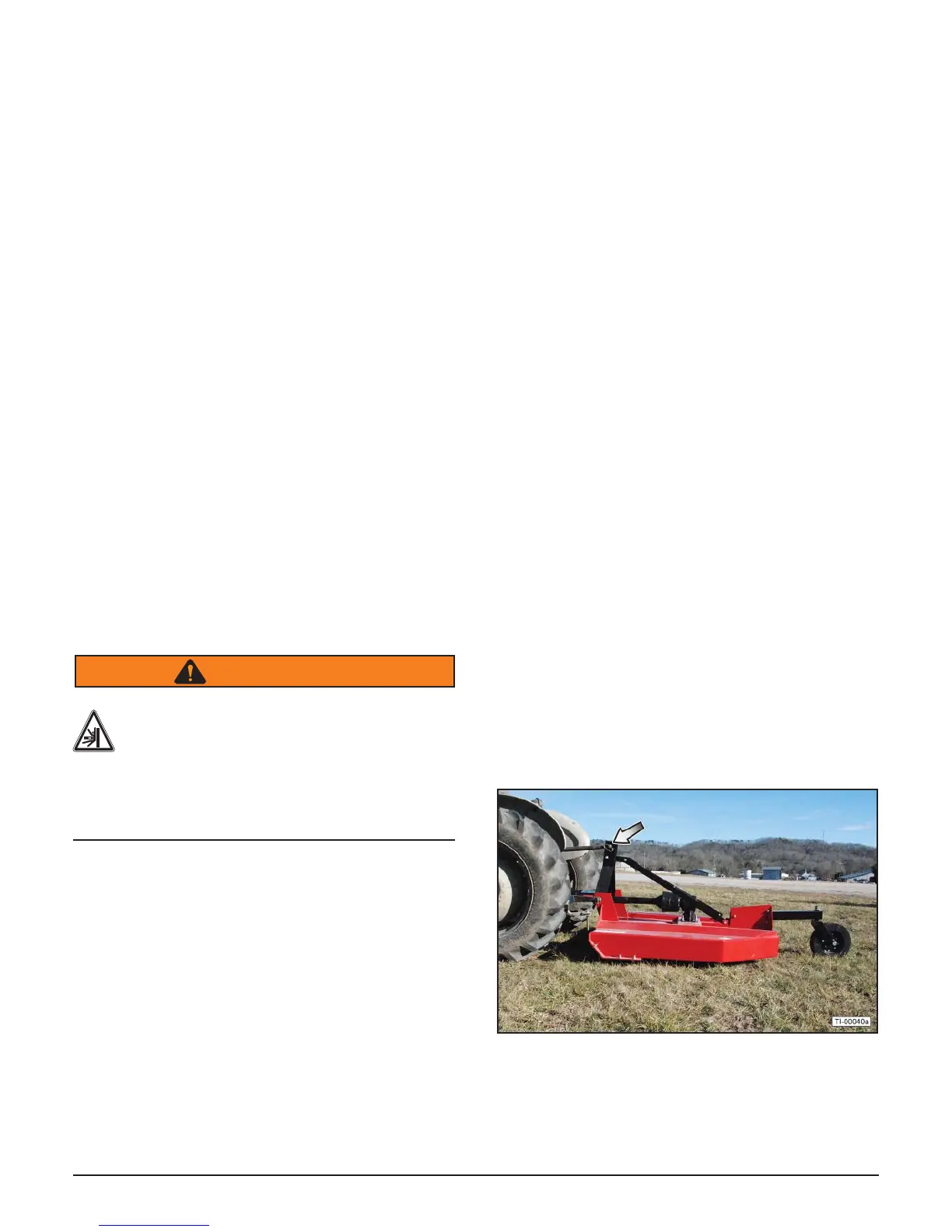

6.3 Attaching to Tractor

Use caution when connecting the rotary cutter to the

tractor. The rotary cutter should be securely resting at

ground level or setting on blocks. Keep hands and feet

from under the deck and clear of pinch points between

the tractor hitch arms and rotary cutter hitch pins.

WARNING

Crush Hazard

Crush hazard between hitch and implement.

Do not allow anyone to stand between the

hitch and implement during hook-up

operations. Never operate the hydraulic

3-point lift controls while someone is directly

behind the tractor.

1. Shorten or remove the tractor drawbar to avoid

interference when raising and lowering the rotary

cutter.

2. Board the tractor and start the engine. Position the

tractor with the 3-point lift arms positioned at the

same height and to the outside of the rotary cutter

hitch pins.

Note: Set the 3-point lift control to “Position Control”

so that the lift arms maintain a constant height

when attaching the rotary cutter. See the tractor

Operator’s Manual for correct settings when

attaching 3-point equipment.

3. Turn off the tractor engine and dismount.

4. One lift arm at a time, insert hitch pin through the lift

arm holes and install retaining pin.

5. Walk around to the opposite side and repeat the

procedure for remaining lift arm and hitch pin.

6. Extend or retract 3-point top link to align its end hole

with the holes of the rotary cutter’s top link. Insert

the top link hitch pin and insert the retaining pin into

the hitch pin.

7. Adjust any lower link check chains, guide blocks,

or sway blocks to prevent the rotary cutter from

swaying side-to-side and possible contact with the

tractor rear tires.

6.4 Detaching from Tractor

1. Move the rotary cutter to a level storage location

and lower it to the ground or onto blocks. Park the

tractor, place the transmission in park or neutral,

and apply the parking brake. Lower the rotary cutter

to the ground, shut down the engine, remove the

key, and wait for all motion to come to a complete

stop before exiting the tractor. Before disconnecting

the rotary cutter, the PTO must be disengaged and

blade rotation at a complete stop.

2. Make sure the rotary cutter is resting securely

on the ground or blocks before attempting to

disconnect it from the tractor. Use extreme care to

keep feet and hands from under the rotary cutter

and clear of any pinch points caused by the tractor

hitch arms and rotary cutter hitch pins.

3. Extend the tractor 3-point hitch top link to remove

tension on the top link hitch pin. When the pin is

loose and easy to rotate, remove the pin from the

rotary cutter.

Loading...

Loading...