1200-1600 Series Rotary Cutters 46 Titan Implement, LLC

August 2016 (423) 334-0012

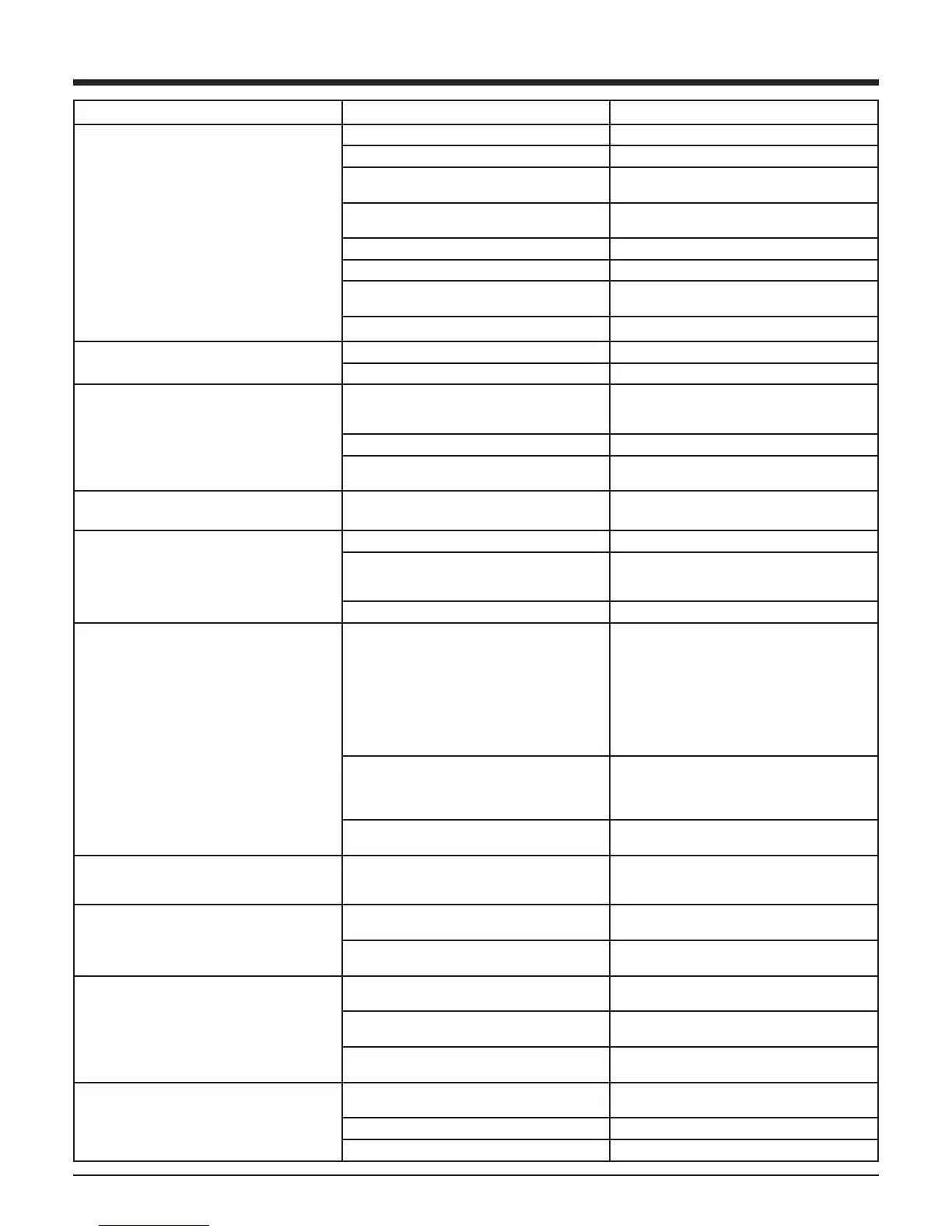

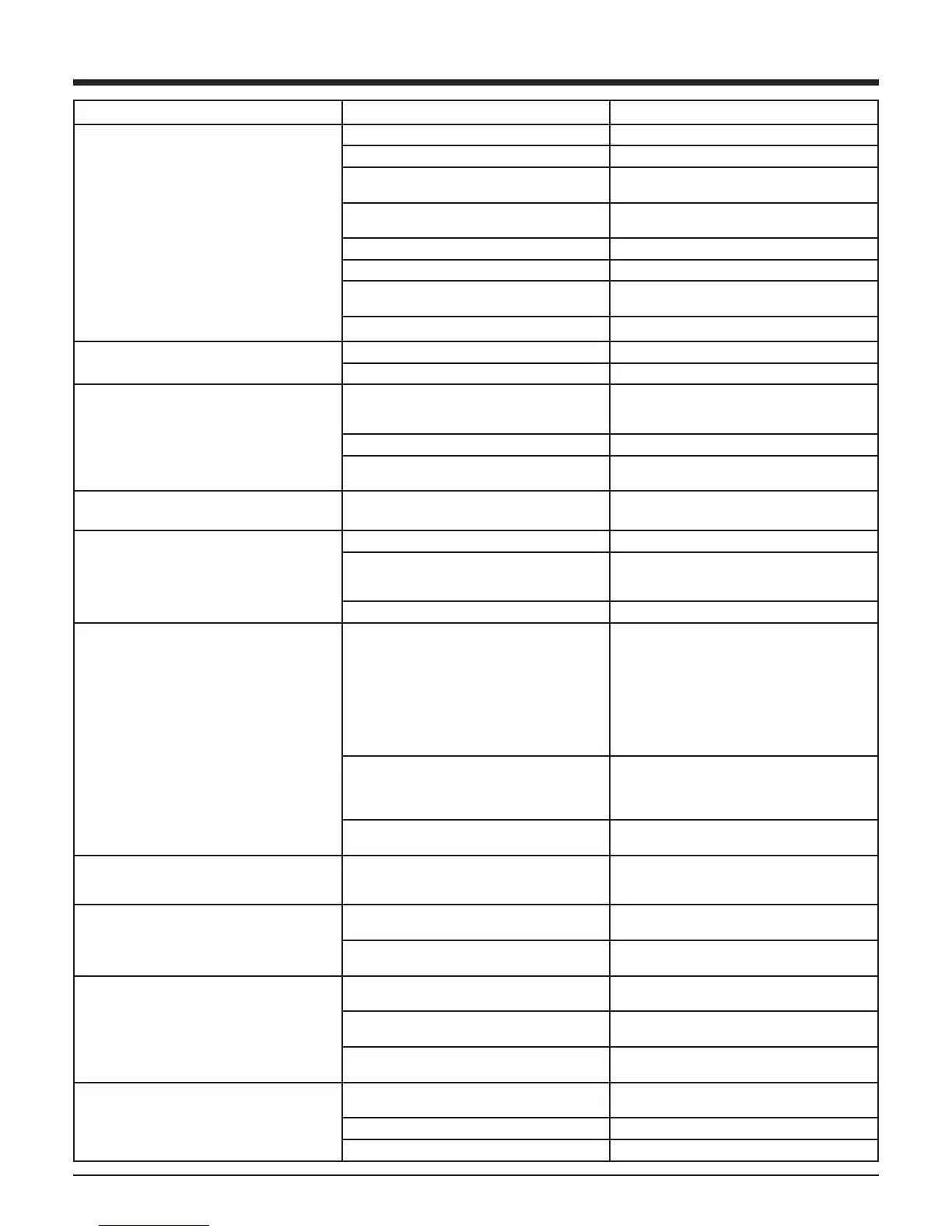

10. Troubleshooting

PROBLEM CAUSE SOLUTION

Uneven cut. Excessive ground speed. Reduce ground speed.

Blades worn, dull, or bent. Replace blades.

Mower not level side-to-side. Adjust. Refer to “6.3 Attaching to Tractor” on

page 33.

Improper height adjustment. Adjust rotary cutter height. Refer to “6.5

Setting the Rotary Cutter” on page 34.

Low tractor tire pressure on one side. Adjust tire pressure. (Refer to OEM manual).

Turning too fast. Reduce ground speed when turning.

Tractor tires push grass down. Adjust your tractor wheel spacing.

(Refer to OEM manual).

Damaged cutter pan. Repair or replace as necessary.

Uncut material. Excessive ground speed. Reduce ground speed.

RPM too low. Maintain 540 RPM PTO speed.

Windrowing. Material heavy and lush. Raise the front of rotary cutter relative to the

rear. Refer to “6.5 Setting the Rotary Cutter”

on page 34.

Excessive ground speed. Reduce ground speed.

Conditions too wet. Wait for conditions to dry. Reduce ground

speed.

Grass cut lower in center of swath than at

edge.

Height of rotary cutter lower at rear or front. Adjust rotary cutter height and attitude so that

rear and front are within 1/2” of same height.

Streaking conditions in swath. Blades dull. Sharpen or replace blades.

Blades unable to cut that part of grass

pressed by path of tractor tires.

Slow ground speed of tractor but

maintain 540 RPM PTO speed. Cutting lower

will help.

Conditions too wet for mowing. Allow grass to dry before mowing.

Material discharges from cutter

unevenly; bunches of material along swath.

Material too high and too much material. Reduce ground speed but maintain 540 RPM

at tractor PTO or make two passes over

material.

Raise rotary cutter for the first pass and lower

to desired height for the second and cut at 90°

to first pass.

Raise rear of rotary cutter high enough to

permit material to discharge but not so high as

to cause conditions listed above.

Grass wet. Allow grass to dry before mowing. Slow

ground speed of tractor but keep engine

running at full PTO RPM. Cutting lower will

help.

Rear of rotary cutter too low, trapping material

under cutter.

Adjust rotary cutter height and attitude.

Rotary cutter will not cut.

(Shear bolt drive only)

Shear bolt sheared. Install new shear bolt. Refer to “9.8 Shear

Bolt Replacement (If Equipped)” on page

43.

Rotary cutter will not cut all the time.

(Slip clutch drive only)

Slip clutch slipping. Adjust slip clutch. Refer to “9.10 Slip Clutch

Adjustment” on page 44.

Burnt or damaged clutch facing. Rework clutch or replace according to OEM

manual.

Blade bolts working loose. Bolts not tightened. Tighten bolts. Refer to “9.5 Blade Servicing”

on page 42.

Bolt hole elongated or oversized. Replace blade carrier Refer to “9.6 Blade

Carrier Removal” on page 43.

Lockwasher broken. Replace lockwasher. Refer to “9.5 Blade

Servicing” on page 42.

Gearbox noisy. Low lubricant level. Add grease. Refer to “9.3 Driveline

Lubrication” on page 42.

Rough gears. Run in or replace gearbox.

Worn bearing. Replace gearbox.

Loading...

Loading...