Titan Implement, LLC 43 1200-1600 Series Rotary Cutters

(423) 334-0012 August 2016

9.5.3 Blade Sharpening

CAUTION

Sharp Object Hazard

The grinder may catch on the blade during

sharpening, propelling it forcefully. To

prevent the possibility of serious injury, make sure

blades are secured against movement while

sharpening.

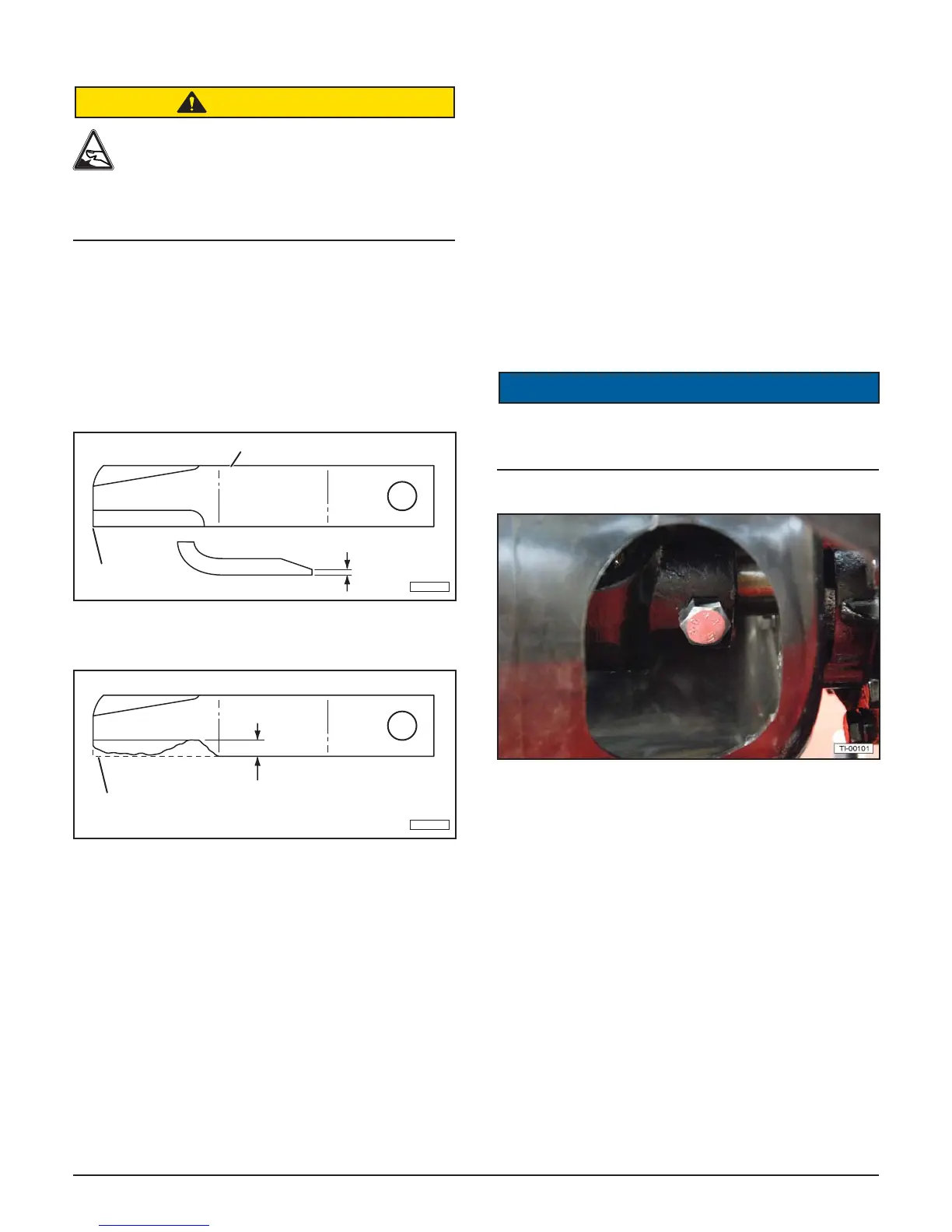

When sharpening blades, always sharpen both blades

at the same time and grind the same amount on each

blade to maintain balance. Unbalanced blades will

cause excessive vibration, which can damage gearbox

bearings. Vibration may also cause structural cracks

to the rotary cutter. Follow the original sharpening

pattern. Do not sharpen blades to a razor edge, leave

a 1/16” blunt edge. Do not sharpen the back side of

the blade. Do not heat and pound out the edge.

1/16”

FOLLOW ORIGINAL PATTERN

MAINTAIN

CORNER

TI-00064

Replace the blades when worn more than 1/2” from the

original edge. Always replace blades in pairs.

ORIGINAL

BLADE EDGE

1/2” MAXIMUM

TI-00063

9.6 Blade Carrier Removal

1. Remove the cotter pin and loosen the castle nut on

the gearbox shaft. Do not remove the nut until the

blade carrier is loosened.

2. Use a suitable two jaw gear puller to pull the carrier

off the tapered gearbox shaft.

3. If a gear puller is not available, insert a bar through

the blade bolt access hole with the end against the

blade carrier. Strike the opposite end of the bar

sharply. Rotate the blade carrier 180 degrees and

repeat until the carrier breaks loose.

4. Remove the castle nut and the blade carrier.

9.7 Blade Carrier Installation

1. Clean the splines on both the blade carrier and the

output shaft.

2. Position the carrier on the gearbox output shaft and

install the castle nut. Tighten the nut to a minimum

450 ft. lbs.

3. Strike the carrier near the hub several times with

a heavy hammer to seat the hub. Use care not to

strike the nut or the end of the shaft.

4. Retighten the nut to 700 ft. lbs.

5. Install the cotter pin and spread the tangs.

9.8 Shear Bolt Replacement (If Equipped)

NOTICE

Always use an approved Grade 2 shear bolt as a

replacement part. Using a hardened bolt or shear pin

may result in damage to driveline or gearbox.

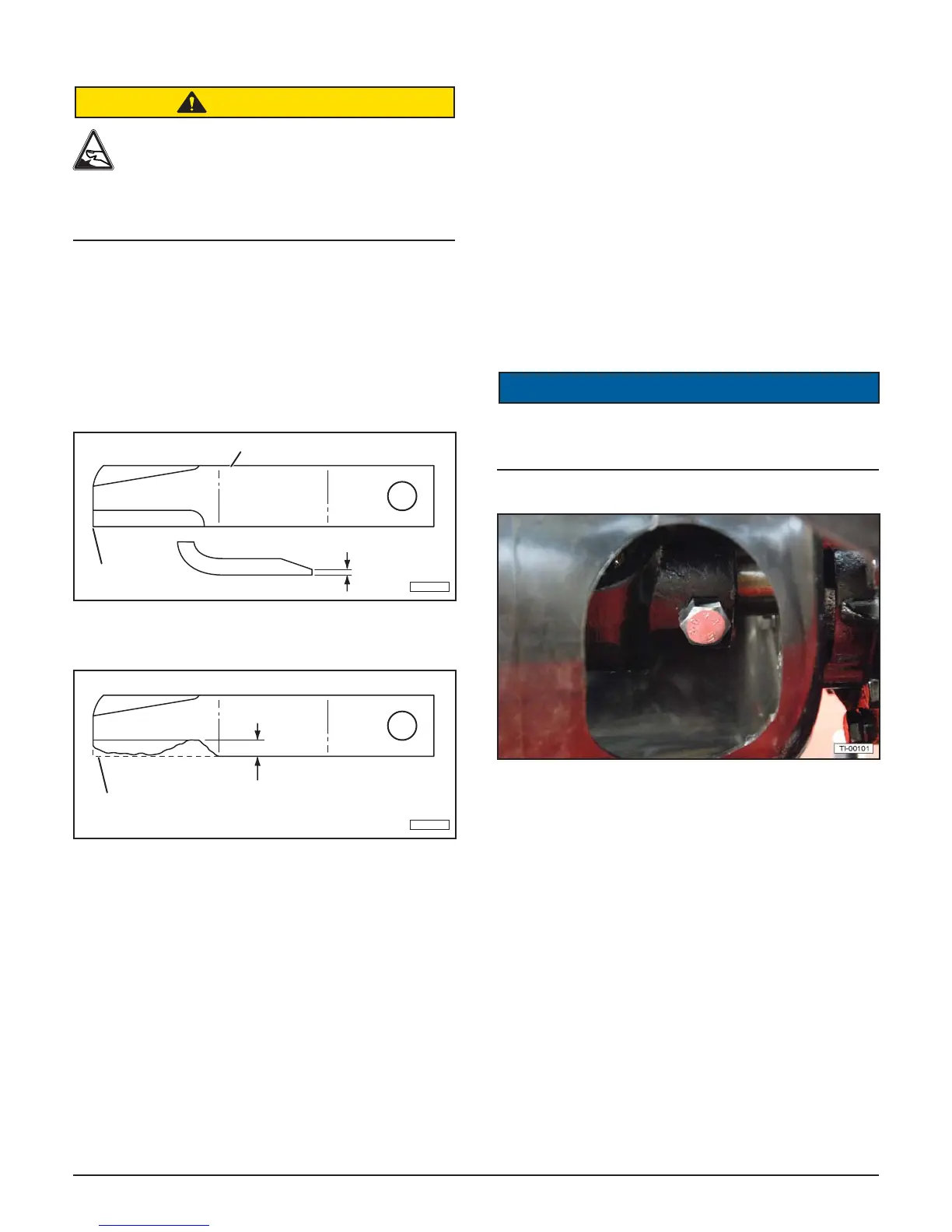

1. Open the access covers on the gearbox shield bell.

2. Rotate the driveline to align shear bolt with the

access hole in the gearbox shield. Remove the

damaged shear bolt.

3. Align the holes in the U-joint and shaft.

4. Install shear bolt and secure with lock nut.

5. Close the access covers on the gearbox shield bell.

9.9 Slip Clutch Operational Check

The slip clutch serves as overall protection for the

tractor, driveline, and gearbox. Even though new

clutch assemblies are “run-in” and checked for torque

prior to shipment, re-adjustment may be advisable

if the clutch has been exposed to weather for an

extended period of time. The clutch facing and plates

should be inspected for rust and/or corrosion. After the

rotary cutter has been stored for thirty days or more,

perform the following check:

Loading...

Loading...