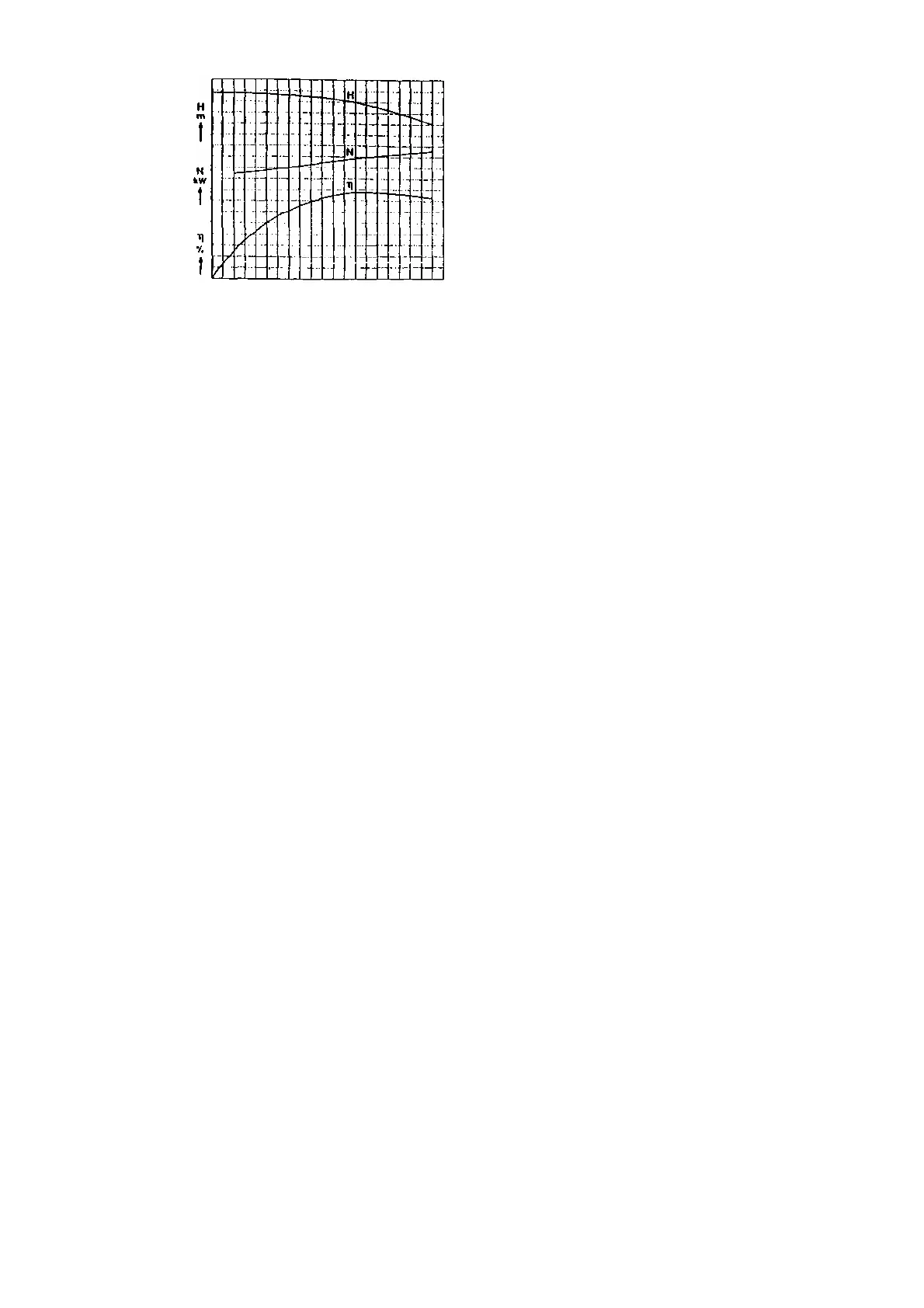

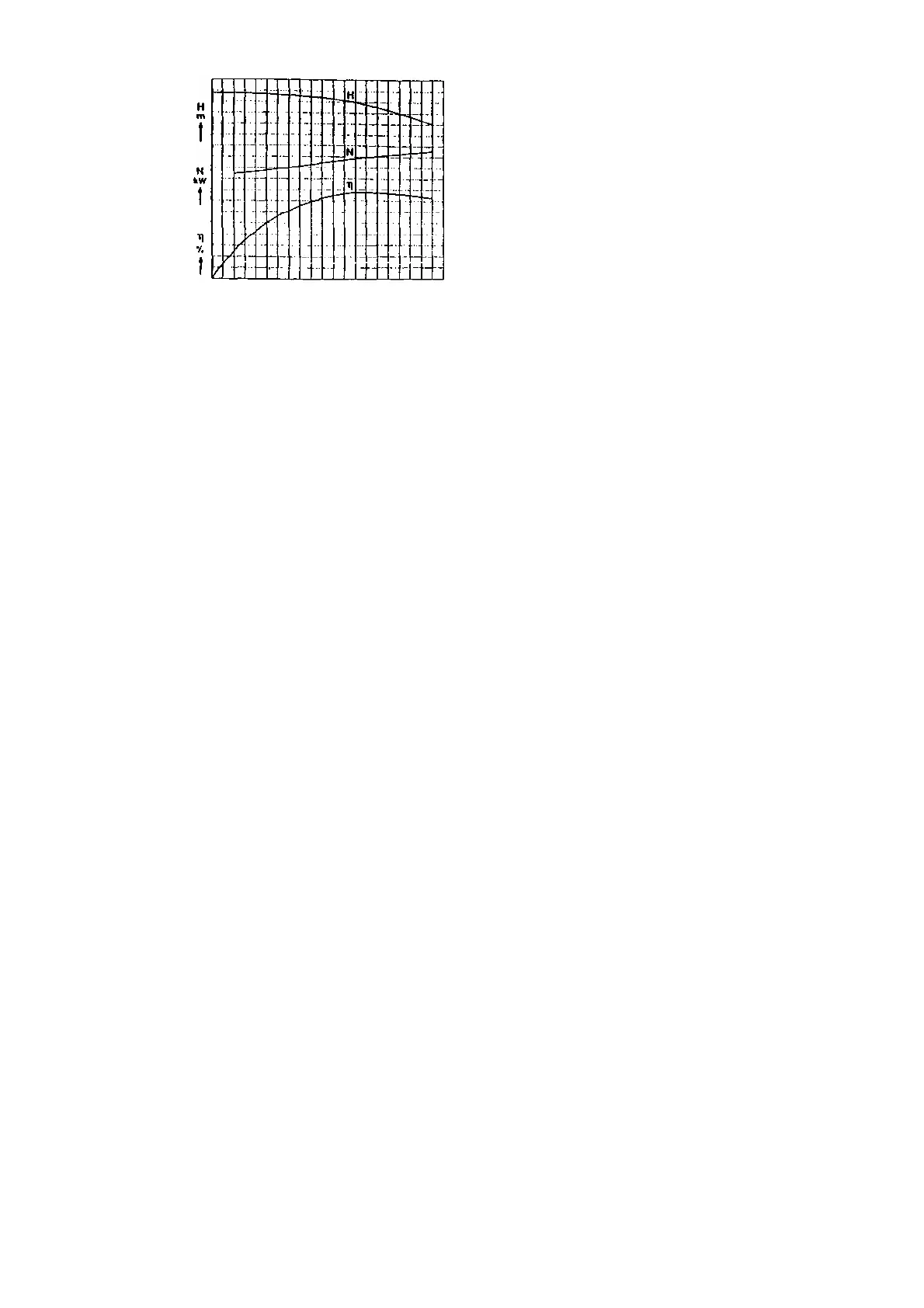

Fig. 8 Characteristic curves at constant pump speed

Fig. 8 illustrates the fact that the power absorbed by the pump does not decrease proportionately with the reduction in

pump capacity; on the contrary, the power absorbed at shut-off head (capacity Q = O) is quite considerable. This absorbed

power is transformed almost wholly into heat within the pump, and this will rapidly lead to over heating and vapor formation in

the pump, when it is operated for any length of time against a closed discharge valve, or at very low through puts; this is

particularly true in the case of powerful drivers and hot fluids (high pumping temperatures). In order to prevent vapor formation

which could endanger the pump, it is essential to ensure that a certain minimum flow always passes through the pump and

carries off the internally generated heat. For this purpose, we recommend the provision of a BY-PASS NON-RETURN VALVE,

or automatic leak-off valve (see fig. 14 and 14 a), which automatically opens a by-pass line when the pump capacity drops

below a certain figure.

If no such valve is incorporated in the installation, it is important to remember that the pump should never be operated

below a certain minimum flow, nor against a closed discharge valve. After running the pump up to operating speed against a

closed discharge valve, on start-up, the discharge valve should immediately be opened.

When pumping hot or highly volatile liquids, and when operating the pump under suction lift conditions, care should be

taken to ensure that the pressure at pump suction nozzle is adequate, i. e. at least as high as stated in the confirmation of

order; otherwise vapor formation and cavitation will occur, which may damage the pump, particularly the first stage impeller and

the balancing device. If the discharge pressure is lower than that for which the pump was designed, the capacity will increase

correspondingly and this may result in over loading the balancing device or the motor, which will run excessively hot.

3. Erection

1.1. Erection the pump

Correct and skilled erection on an adequate foundation is an essential pre-requisite for trouble-free operation of the

pumping set.

The following points should be scrupulously observed in order to avoid operating troubles and damage to the pump :

1. Make sure that the foundation has set properly before placing the pump on it.

2. Level up the base plate by means of packing or shims, with the aid of a spirit level.

3. Check coupling alignment for parallelism and concentricity, and re-align same if necessary, ( see section 3.2.1.).

4. Grout in the base plate and the foundation bolt pockets with a quick setting cement mixture in I : 2 ratio.

Make sure that no empty spaces or cavities are left beneath the base plate.

5. When the cement has set completely, tighten the nuts on the foundation bolts evenly and firmly.

6. Connect the piping to the pump nozzles without imposing any stress or strain on the pump. Remember that pumps should

not be used as anchorage points for the piping.

- 7 -

Loading...

Loading...