If the carbon rings and rotary rings have to be renewed, they should never be placed anywhere with their working faces

down, since even the slightest scoring of the highly finished surfaces may result in leakage.

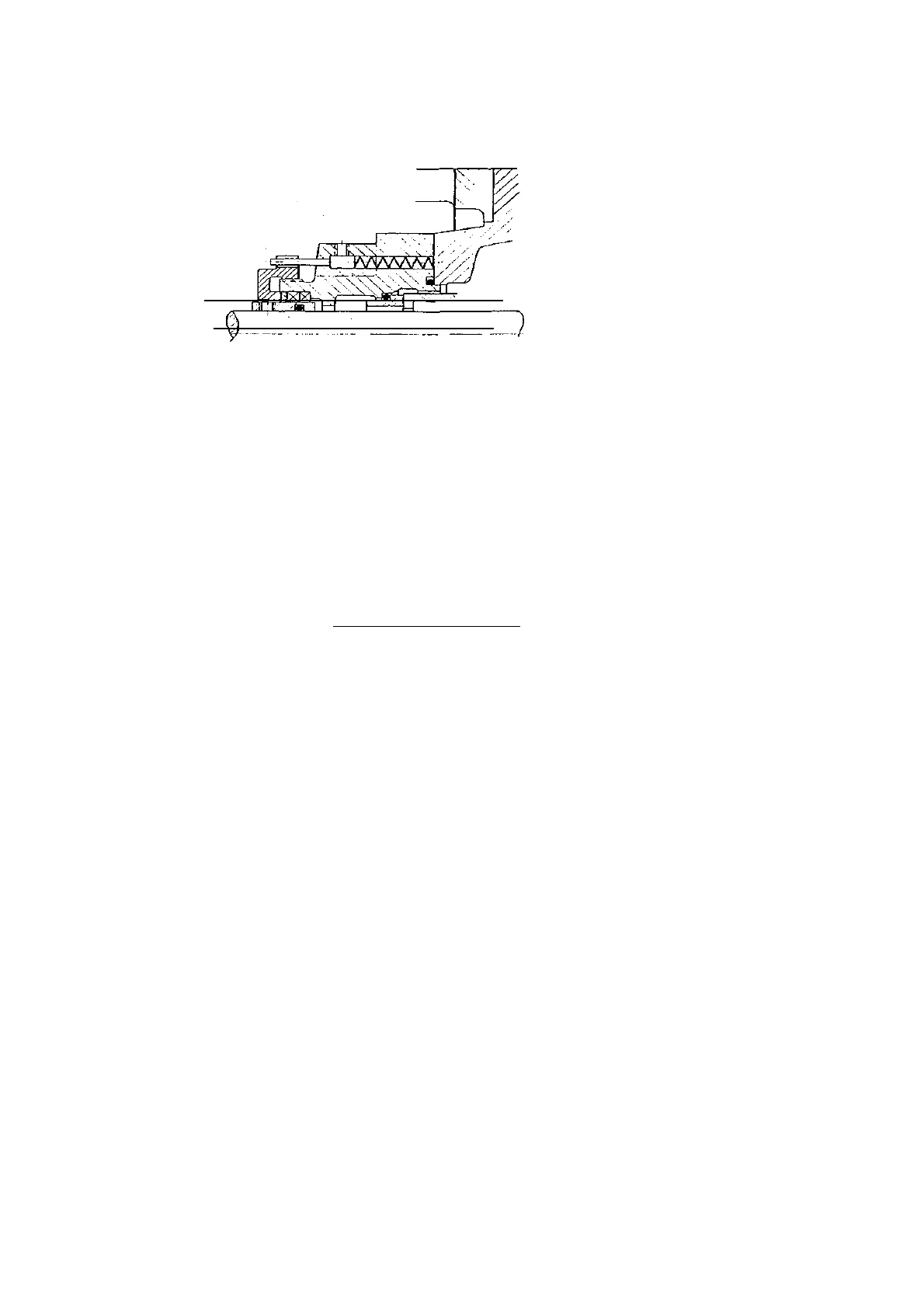

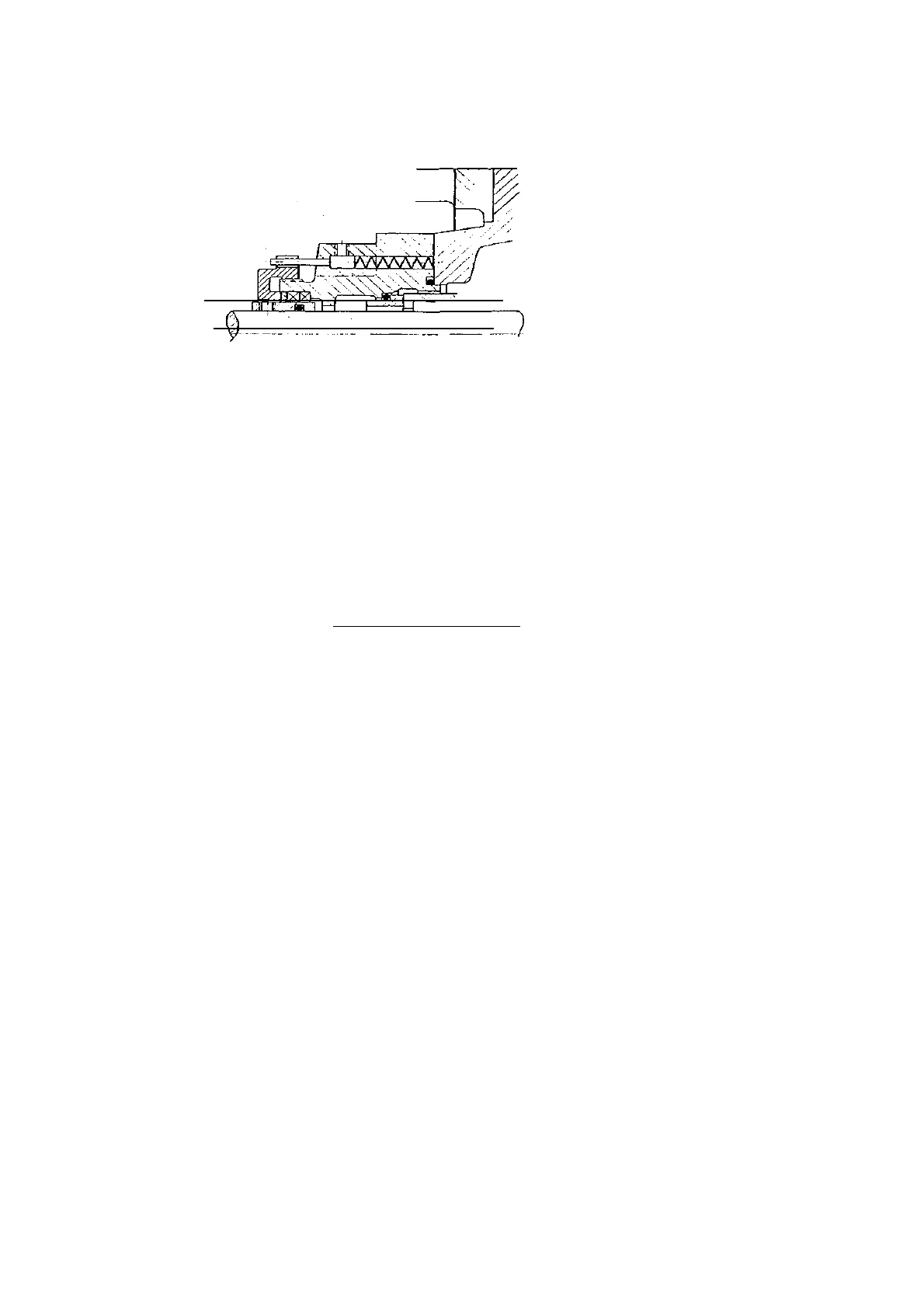

Fig. 17 Auxiliary Stuffing Box

1758:15

4.4.4. Maintenance of bearings

Before the pump is first commissioned, or after it has been idle for a prolonged period, the oil level in the bearings must be

checked by dipstick or overflow, and its appearance should also be checked. It must not be cloudy (condensation!). Any topping

up of oil must be carried out with scrupulous cleanliness, filling being done through the oil cap on the bearing. If necessary, all

remains of the old oil can be completely drained off by unscrewing the drain plug, and cleaned out by taking off the bearing

covers (3600, 3610). Any flushing must be done with petrol, benzolle or wash oil.

The first oil change in a new bearing should be made after 200 hours of operation; subsequent changes after every 1,000

further hours of operation. Only use well known brands of lubricants for antifriction or plain bearings, to the following

specification:

Viscosity at 120 °F = 50 °C : 20 to 45 cSt ( Approx, SAE 10 W ).

Flash Point : 380 to 450 °F (195 to 230 °C)

Pour point, below : 15 ° F (-10 °C)

Ash content, below : 0.05 %

The temperature of the bearings, the oil levels, and the quiet running of the pump must be kept under careful observation

the whole time it is running. The temperature of the bearings must never exceed 175 °F (80 °C) and, with this as a maximum, it

must never be more than 120 °F (50 °C) above ambient temperature. If the oil should become contaminated with water or any

other foreign matter, the pump must be stopped at once, and the bearings thoroughly cleaned and refilled with oil.

Any cooling of the bearings must be done with pure, cold water, and the remarks on cooling of stuffing boxes (section

4.4.2.) apply equally to the bearings.

4.4.5. Maintenance of the thrust balancing device

Trouble free operation of the pump is dependent on the correct functioning and good condition of the balancing device.

If an isolating valve is incorporated in the balance water line, it should always remain open while the pump is running,

irrespective of whether the balance water is discharged into the open, into a vessel, or returned to pump suction.

The working life of the balance disc (6010) and balance disc seat (6020) will depend, amongst other factors, on the number

of stops and starts of the pump during normal operation.

The wear on these components will cause the pump rotor to move gradually towards the suction end of the pump, After the

wear has attained a certain limit, the danger will a rise of the pump rotor fouling the casing, particularly the wear rings (5020).

Therefore the position of the rotor shaft should be checked at regular intervals during running.

- 16 -

Loading...

Loading...