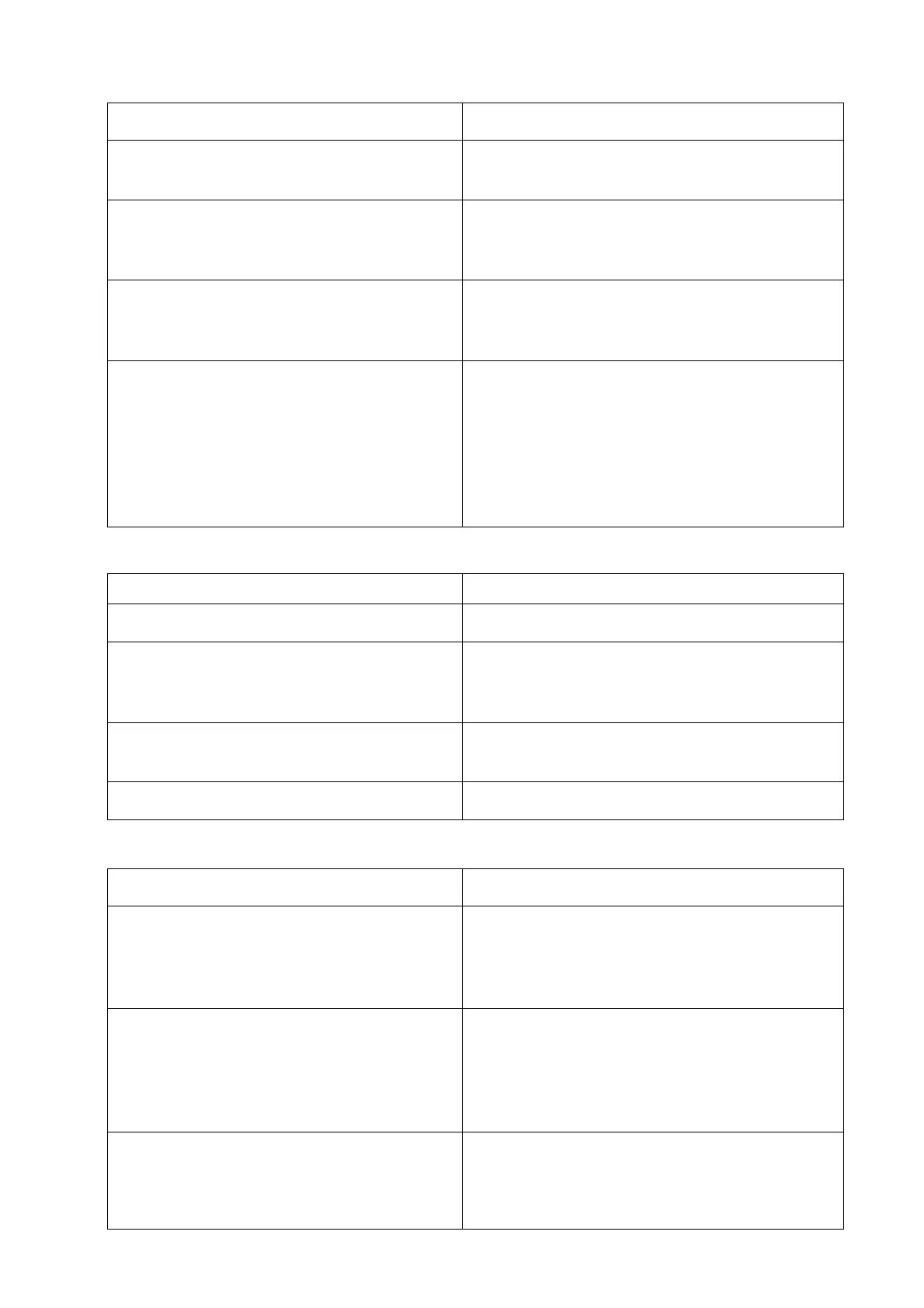

4. 5. 5. Stuffing box leak

Possible cause Remedy

1. Worn, unsuitable or badly fitted packing. Repack the stuffing box, carefully observing instruction on page

16.

2. Scoring or grooving of the shaft protecting sleeve, due to

excessive tightening askew of the stuffing box gland.

The shaft protecting sleeve should be repolished or renewed.

When the stuffing box has been repacked, tighten the gland

carefully and evenly.

3. Insufficient cooling water, or fouling of cooling water

chambers.

Remove cooling water covers, and thoroughly clean out the

cooling surfaces in the stuffing box. Make sure that an adequate

supply of clean cooling water is available.

4. The pumps runs rough, i.e. the shaft chatters. No stuffing box can remain tight forever if the shaft chatters. Firs

of all; the coupling alignment and bearing clearance should be

checked, and new bearings fitted if necessary. If this does not

cure the trouble, open up the pump, and check the shaft for true

running. Also rebalance the rotating assembly and check all

running clearances. When reassembling the pump, carefully

follow the instruction in this manual.

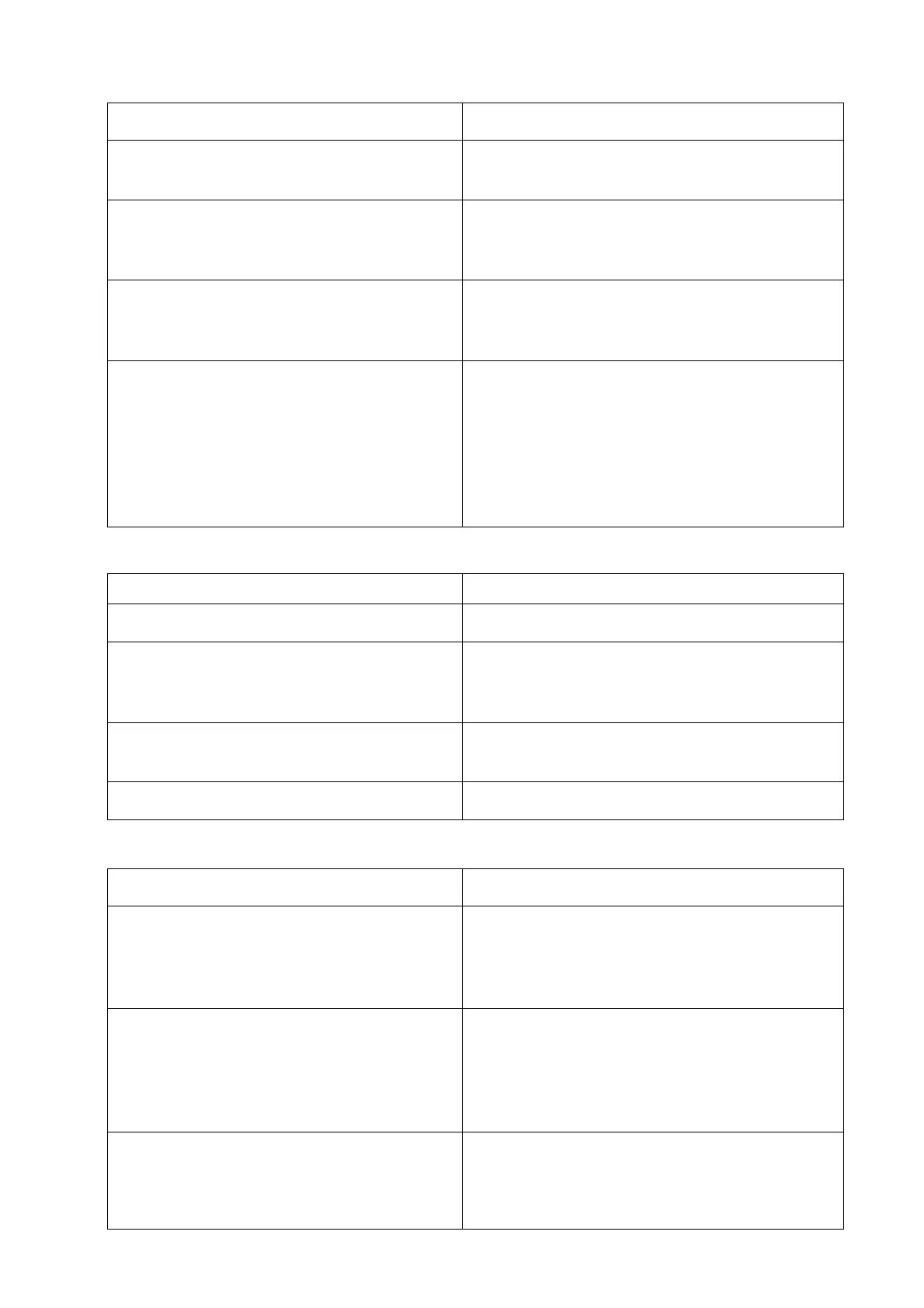

4. 5. 6. Excessive bearing temperature

Possible cause Remedy

1. The set is misaligned. Check alignment at the coupling as described in Section 3.2.1.

2. The piping causes the pump to warp. Ensure that the piping transmits no stress or strain onto the

pump by altering the piping layout if necessary. Realign the

pumping set.

3. The prescribed clearance between coupling halves

has not been observed during erection.

Correct the coupling clearance. See foundation drawing for

measurements.

4. Oil level inadequate, or inferior oil quality. Top up, or change if necessary (see 4.4.4).

4.5.7. Excessive wear of balancing device

Possible cause Remedy

1. The fixed clearance gap between the rotor and the

discharge casing (1070), or on pump sizes MML 200-

350 the bush (118) is too wide; this may be caused by

corrosion or mechanical wear.

Re-establish the correct radial clearance between the parts

concerned, and renew bush (118) if required. Check that the

bearings have correct clearance and seat properly. Check the

shaft for true running, and if necessary fit a new shaft.

2. Thrust balancing is impaired by reason of an excessive

clearance between the impeller neck (2300) and the

wear ring (5020) or the diffuser (1710) ; on pump sizes

MML 200-350, between diffuser bush (119) and spacer

sleeve (5210).

True up impeller neck or bore of the diffuser and renew wear ring

(5020) or spacer sleeve (5210).

3. Thrust balancing impaired by reason of axial

displacement of the impellers in relation to the diffusers.

Re-establish the correct axial location of the rotating assembly

by either lengthening or shortening the spacer sleeve (5252) in

the discharge casing, or in the case of pump sizes MML 40-125,

adjust the hub of the balance disc (fig. 21).

- 20 -

Loading...

Loading...