4. 3. Shutting down the pump

1. Close discharge valve.

2. Switch off driver, and observe pump rotor running down to a stand still.

3. Turn off cooling water, when the pump has cooled down below 105 °C (220 °F).

This only applies to pumps with cooled stuffing boxes or bearings.

4.4. Maintenance

The pump and driver must be kept under careful observation the whole time the set is running.

4.4.1.Maintenance of pump

We recommend keeping a log book in which the operation of the pump should be regulary recorded. The data recorded

should include pump capacity, suction and discharge pressures, balance water pressure, water temperature, bearing

temperature, and pump speed, as well as the operating data of the driver (output and speed of electric motor, diesel engine or

turbine). The switching on and switching off times should also be recorded to enable the total number of operating hours of the

pump to be ascertained at any time.

A further column for "remarks" should be provided, in which details of maintenance and repair work can be entered. This

log book will thus enable a clear picture of the condition of the pump to be kept at all times.

Pumps erected on new foundations should be subjected to an alignment check at the coupling from time to time, to

ascertain whether any settlement in the foundations may have resulted in misalignment of the pumping set. This check should

also be recorded in the log book.

Actual maintenance of the coupling is restricted to periodical inspection of the rubber components or flexible members and

their renewal when necessary. Rubber parts should be kept well clear of contact with oil or grease.

4.4.2. Maintenance of soft-packed stuffing boxes.

The stuffing boxes will give trouble - free and satisfactory service providing they are carefully and correctly packed and

maintained. The pumps are delivered with their stuffing boxes unpacked, and one set of packing for each box is included in the

consignment. Before packing the box, the packing compartment and shaft sleeve should be thoroughly cleaned. The individual

rings should be cut from the packing coil with a clean scarf joint, stretching the coil flat in a wooden jig, as shown in Fig. 15. The

rings must be cut to the correct length, so that the ring butts are in light contact with each other at the scarf joint, when the ring

is wrapped around the shaft protecting sleeve.

If the rings are cut too long, they will bulge out at the joint; if they are too short, there will be a gap at the joint. In either case, the

stuffing box will leak as a result.

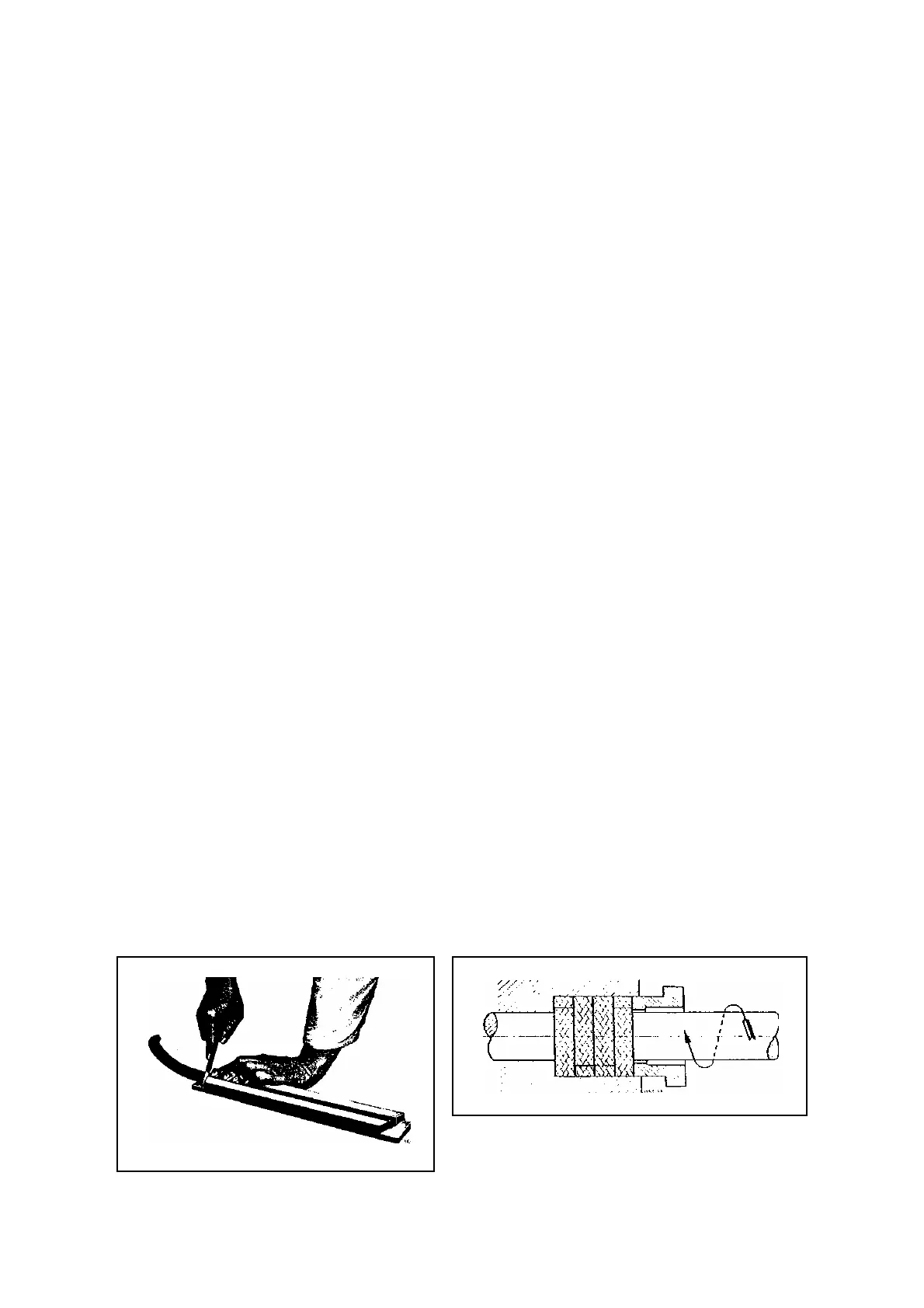

Fig.16 Stuffing Box and Packing Rings

- 14 -

Loading...

Loading...