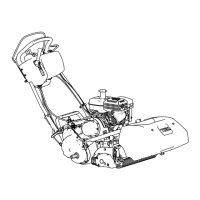

Greensmaster Flex 1800/1820/2100/2120Traction and Reel Drive System Page 4 − 24

Differential Assembly

1. Drum drive housing

2. Straight bushing

3. Flange bushing (4 used)

4. Brake lever

5. Traction lever

6. Square key (2 used)

7. Drum shaft

8. Long spur gear

9. Differential assembly

10. RH traction drum

11. Jam nut

12. Grease seal

13. LH traction drum

14. Ball bearing (2 used)

15. Bearing nut

16. LH hex shaft (LH threads)

17. Straight bushing (2 used)

18. Dowel pin (2 used)

19. Cap screw

20. Flat washer

21. Traction engage lever

22. Retaining ring (2 used)

23. Brake lever

24. Retaining ring

25. LH side plate

26. Washer head screw

27. Lock collar

28. Pin

29. Thrust washer

30. O−ring

31. Spur gear assembly

Figure 27

FRONT

RIGHT

Lubricant

Antiseize

1

3

4

5

6

7

8

9

14

17

18

19

20

21

22

23

24

27

29

3

17

6

3

3

22

28

30

2

26

10

11

12

13

15

16

14

25

70 to 80 ft−lb

(95 to 108 N−m)

140 to 160 ft−lb

(190 to 216 N−m)

75 to 90 ft−lb

(102 to 122 N−m)

Loctite #242

31

Disassembly (Fig. 27)

1. Park machine on a level surface. Make sure engine

is OFF. Remove spark plug wire from the engine spark

plug.

2. Remove traction drums from machine (see Traction

Drums in this section).

3. Slide spur gear assembly from differential assembly

in drum drive housing (Fig. 28).

Loading...

Loading...