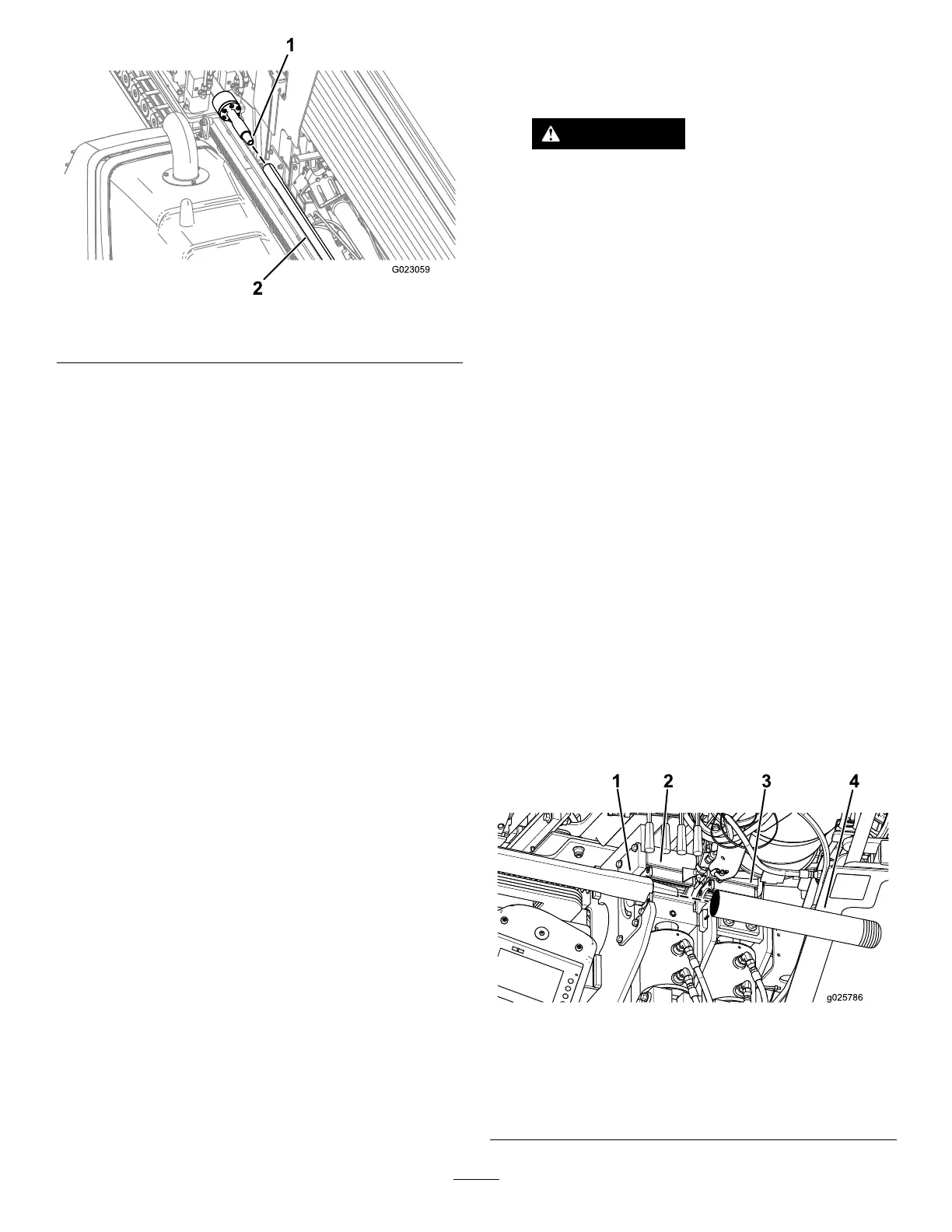

Figure50

1.Drillspindle2.Pipe

7.Continuetomovethedrillcarriageslowlydownthe

frameuntilthemalethreadsonthepipeareunder

thethread-joint-compoundapplicatorandapply

thread-jointcompoundtothethreads.

8.Releaseandretractthepipegripper,rotatingitallthe

wayouttothethirdrowofpipes.

Important:Ensurethatyoufullyretractthe

pipegripperandrotateitallthewayoutorthe

carriagemaycollidewiththegripper,damaging

themachine.

9.Continuetorotatethedrivespindleclockwise,until

themalepipethreadsarefullyseatedintothesonde

housingortheleadbar.

Note:Torquethethreadsto2305N-m(1700ft-lb).

InstallingtheDrillHead

1.Usingtheexit-side-lockouttransmitter,enabletheexit

sidelockout.

WARNING

Ifthedrillrotatesorextendswhileyouor

othersaremanuallyworkingonthedrillbitor

pipeinfrontofthemachine,theworkercould

getcaughtinthebitorpipecausingserious

injury,amputation,ordeath.

•Enabletheexit-sidelockoutonthe

exit-side-lockouttransmitterbefore

approachingthedillbitorpipewhen

attachedtothemachine.Thiswilldisable

thedrillcarriage.

•Donotwearlooseclothingorjewelrywhen

workingonadrillbitorpipeattachedto

themachine.Tielonghairupandoutof

theway.

2.Handthreadtheleadbarontothepipethreadsthen

clearawayfromthefrontofthemachine.

3.Whentheareaisclearofpeople,disabletheexit-side

lockoutusingtheexit-side-lockouttransmitter

(theOK-to-Drilllightonthecontrolpanelshould

illuminate);presstheexit-side-lockout,resetswitchon

thecontrolpanel.

4.Pullthedrillpipeandleadbarbackthroughthepipe

guideandintothewrenches,aligningthethickened

upperjointoftheleadbarwiththeupperwrench

(Figure51).

Important:Donotclampthewrenchonthebody

ofapipeoritmaydamagethepipe.Gripthepipes

onthethickenedareanearthejoint.

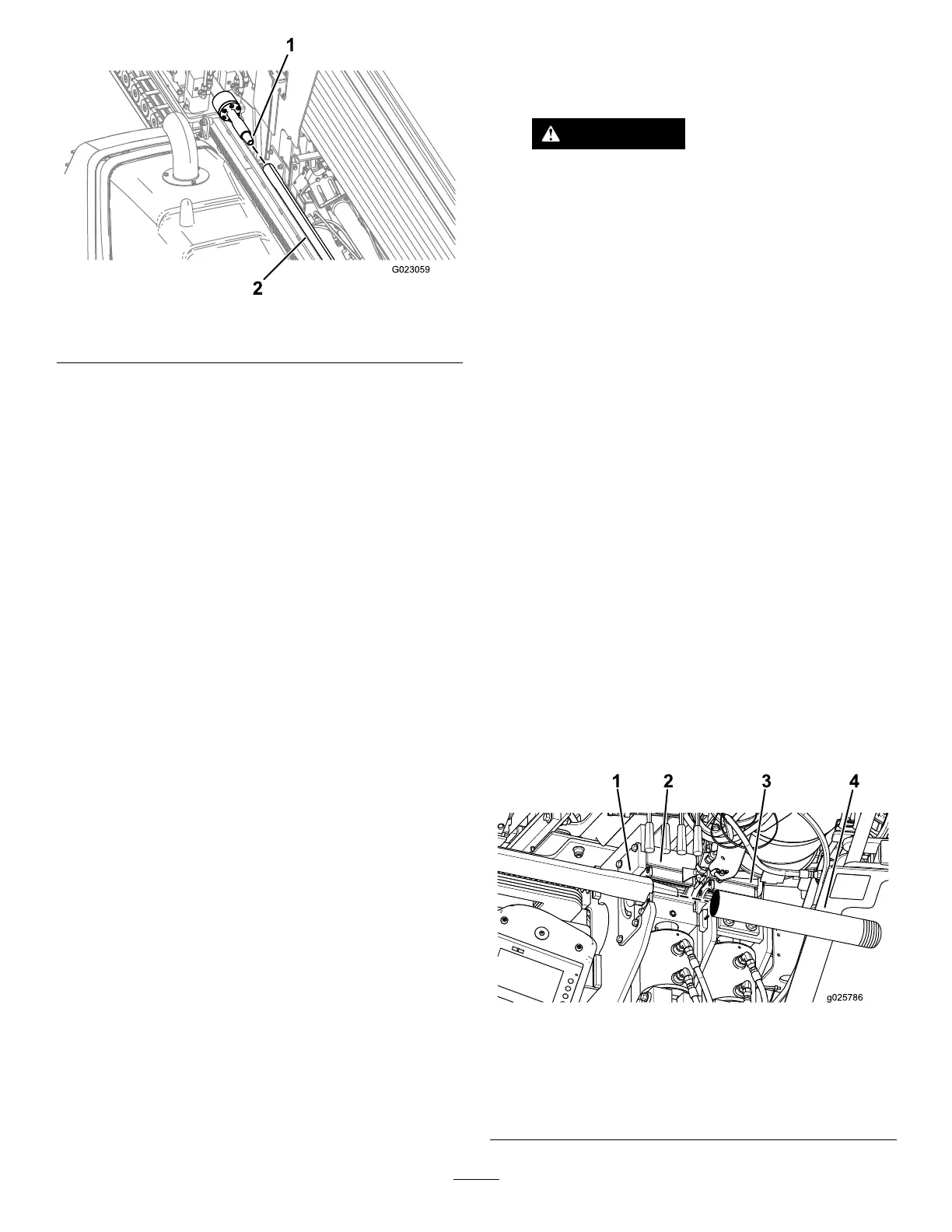

Figure51

1.Drillpipe

3.Lowerwrench(stationary

wrench)

2.Upperwrench

(makeup/breakout

wrench)

4.Leadbar

50

Loading...

Loading...