CheckingtheHydraulicLinesand

Hoses

ServiceInterval:Every2years—Replacemovinghoses.

Inspectthehydrauliclinesandhosesdailyforleaks,kinked

lines,loosemountingsupports,wear,loosettings,weather

deterioration,andchemicaldeterioration.Makeallnecessary

repairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesurethatallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoskin.

HydraulicSystemTestPorts

Thetestportsareusedtotestthepressureinthehydraulic

circuits.ContactyourAuthorizedToroDealerforassistance.

Drilling-uidPump

Maintenance

Servicingthe

Drilling-Fluid-PumpOil

Thedrilling-uidpumpisshippedwithoilinthecrankcase;

however,checktheoillevelbeforeandafteryourststart

theengine.

Thecrankcasecapacityis1.9L(2USqt).

Useonlyhigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher

•Oil:SAE30-weight,non-detergentoilabove0°C(32°F)

ToroPremiumEngineOilisavailablefromyourdealer.See

thepartscatalogforpartnumbers.Also,refertotheEngine

Operator'sManual,includedwiththemachine,forfurther

recommendations.

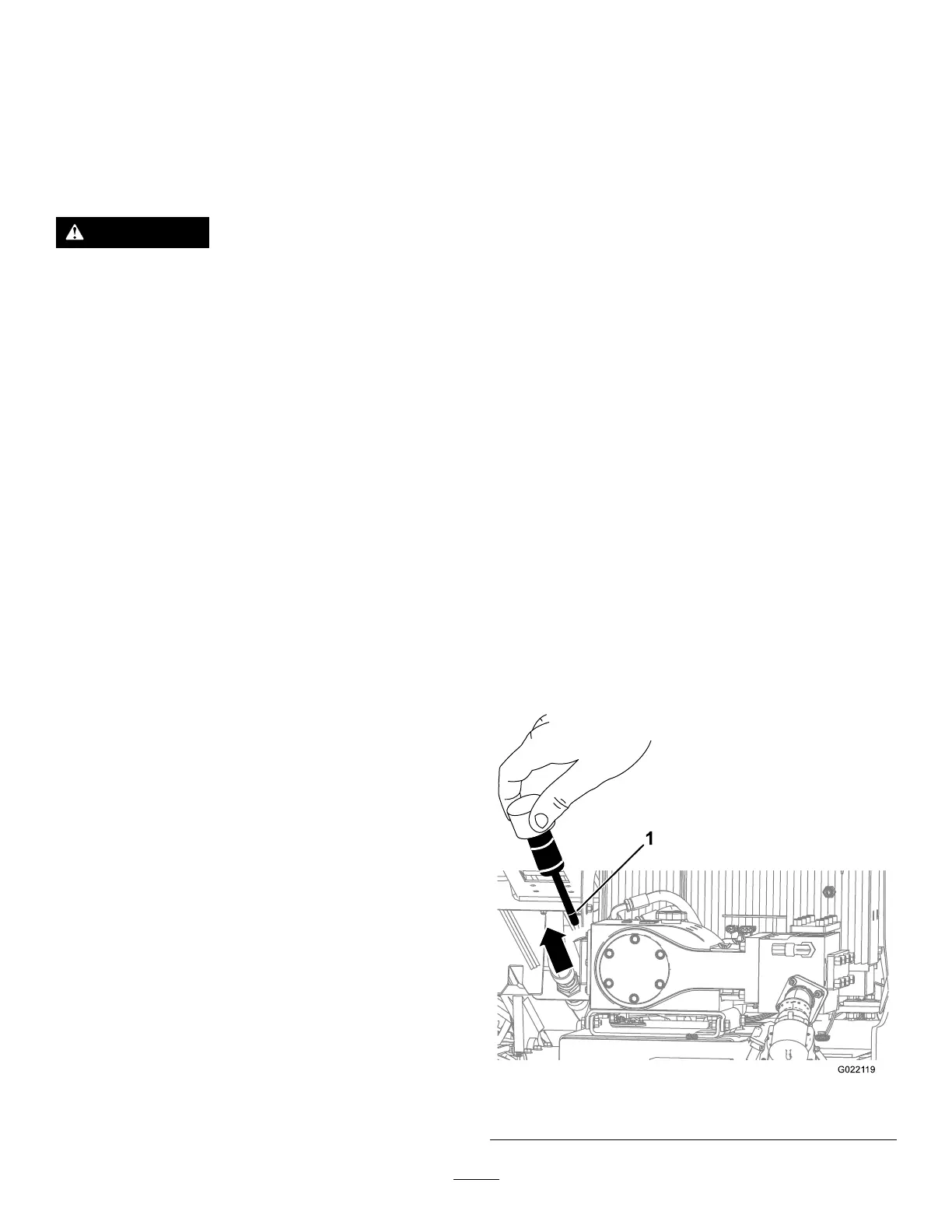

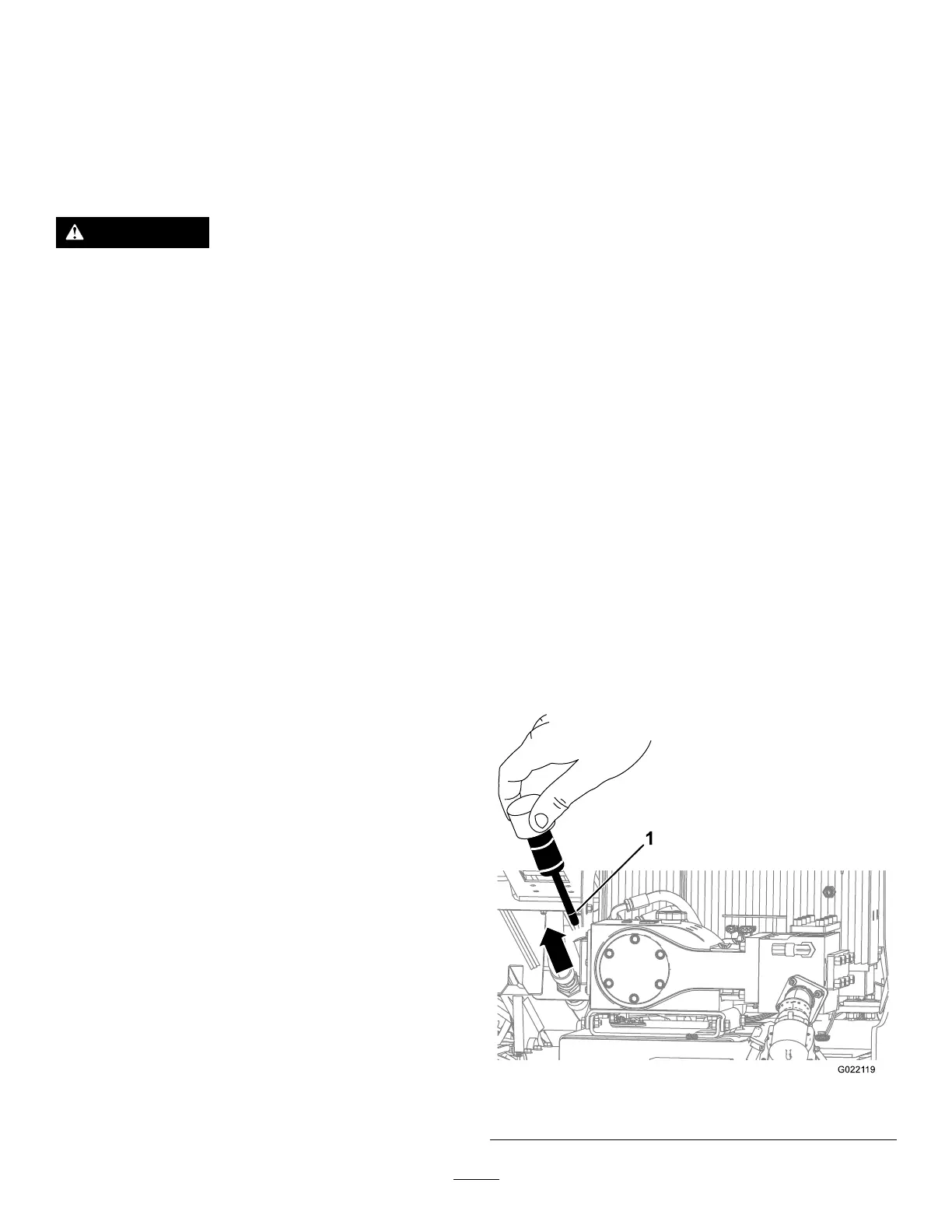

CheckingtheDrilling-Fluid-PumpOil

Level

ServiceInterval:Beforeeachuseordaily—Checkthe

drilling-uid-pumpoillevel.

1.Parkthemachineonalevelsurface,stoptheengine,

andremovetheignitionkey.

2.Opentherearhood.

3.Removetheoildipstick(Figure111).

Figure111

1.Oil-llline

86

Loading...

Loading...