5.Usingtheupperwrench,clamptheleadbarandtighten

ittofullmachinetorque.

6.Usingtheexit-side-lockouttransmitter,enablethe

exit-sidelockout.

7.Doublecheckthedrillheadandbittoensurethatthe

uidportsarecleanandfreefromobstructions.

8.Installthedrillheadontotheendoftheleadbaras

directedbythedrillheadmanufacturer,thenclearaway

fromthefrontofthemachine.

Important:Donotpullthedrillheadintothe

pipeguideoryoumaydamagethemachineorthe

drillhead.

BoringtheEntryShaft

Therstboringstepistocreatetheentryshaft.Inthisstep,

youpushandborethedrillbitandrstfewpipesintothe

groundatananglefrom0to16degrees(withthetracksat

ontheground)untilyoureachthedesireddepthofyour

installation.

Important:Drillandreaminaclockwiserotation.

Ifyouuseacounterclockwiserotationthepipewill

disconnectfromeachotherandmaybedisconnected

underground.

1.Whentheareaisclearofpeople,disabletheexit-side

lockoutusingtheexit-side-lockouttransmitter

(theOK-to-Drilllightonthecontrolpanelshould

illuminate);presstheexit-side-lockout,resetswitchon

thecontrolpanel.

2.Turnonthedrillinguidpumpswitchandallowthe

uidpressuretobuildto200to300psi.

3.Rotatethedrillheaduntilthebitisatthe6o’clock

position.

4.Movethecarriageforwarddrivingthebitstraightinto

thegrounduntiltheentiredillhousingisunderground.

5.Continuepushingforwardandbeginrotatingthedrill

spindleclockwisetoinitiatethedrillingaction.

6.Drillforwarduntilthecarriagereachestheendofthe

frame,thenretractitabout6mm(1/4inch).

AddingDrillPipes

1.Alignthepipejointinthewrenchassembly.

2.Closethelowerwrench(stationarywrench)ontothe

rstpipe.

Note:Thedrillinguidwillautomaticallyshutoff

whenyouactivatetheupperwrench(makeup/breakout

wrench).

3.Pullbackthecarriageapproximately12.7mm(0.5

inch).

Note:Thiswillallowthecarriagetooat,andwillnot

damagethepipethreads.

4.Rotatethedrillheadcounterclockwiseuntilthespindle

iscompletelyremovedfromthepipe.

5.Spraythespindlewiththreadjointcompound,then

returnthedrillcarriagetotheupperendoftheframe.

6.Rotatethepipegrippertotheclosestrowofpipesin

thepipeholder.

7.Lowerapipeintothepipegripperandgripitinplace.

8.Rotatethepipegrippertowardthethrustframe,and

extendituntilthepipeiscenteredovertheframeand

infrontofthespindleonthedrillcarriage.

9.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthespindleintothefemaleend

ofthepipe(Figure50).

Note:Tightenthejointuntilthepipeisrotatingwith

thespindle.

10.Movethedrillcarriageslowlydowntheframe

untilthemalethreadsonthepipeareunder

thethread-joint-compoundapplicatorandapply

thread-jointcompoundtothethreads.

11.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthemaleendofthepipeinto

thefemaleendofthepreviouspipe.Tightenthejoint

untilyoureachnomorethan2,304N-m(1,700ft-lb).

12.Releaseandretractthepipegripper,rotatingitallthe

wayoutpastthethirdrowofpipes.

Important:Ensurethatyoufullyretractthe

pipegripperandrotateitallthewayoutorthe

carriagemaycollidewiththegripper,damaging

themachine.

13.Releasethewrenchandcontinuethedrillingoperation.

SoftwareversionKornewer:Afterloadingtherstpipethe

softwarewillskipthecertainproximityswitchestoimprove

operatorproductivity.Thegripperswillalsofunctionwhen

thepipeloadingcamisextendedandretractedwithout

operatorinput.

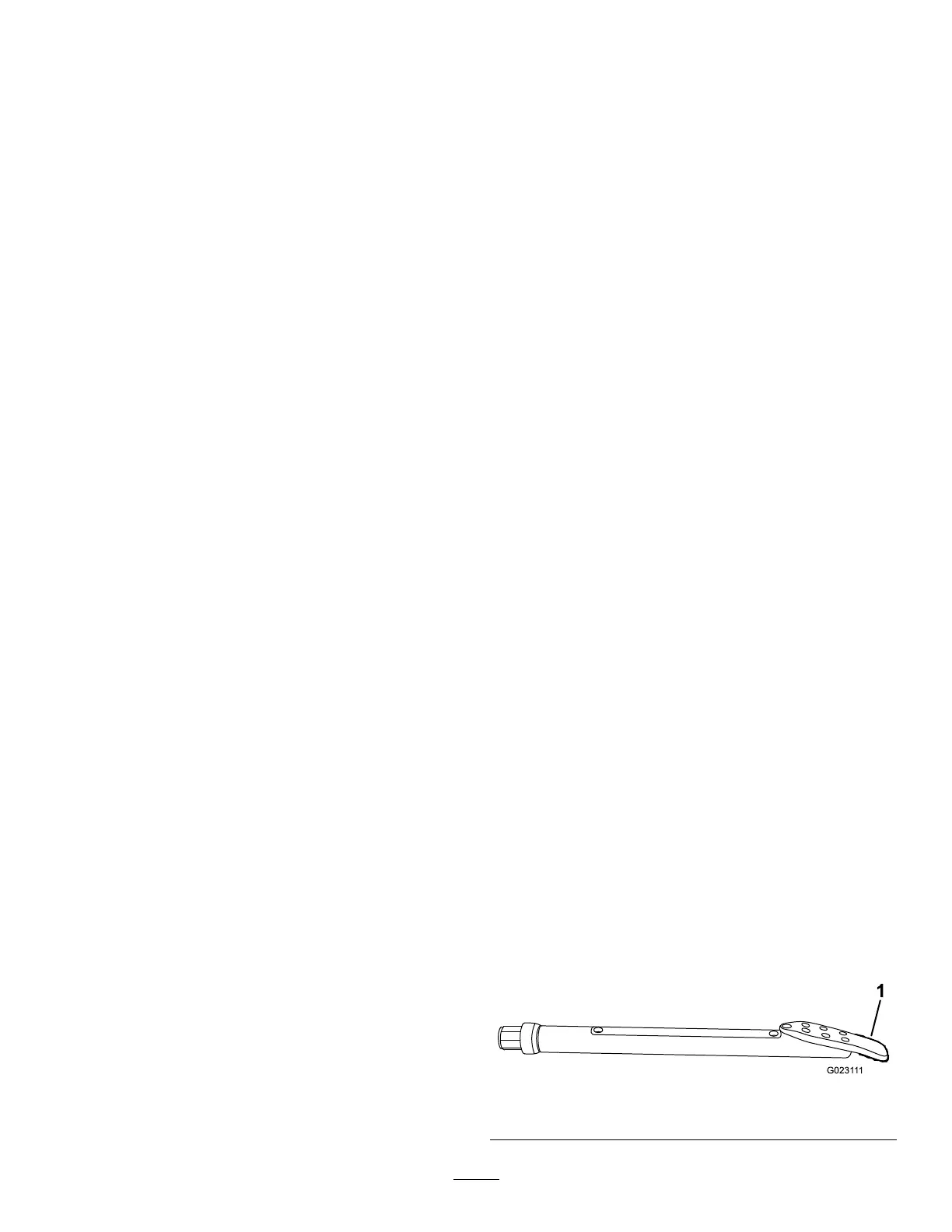

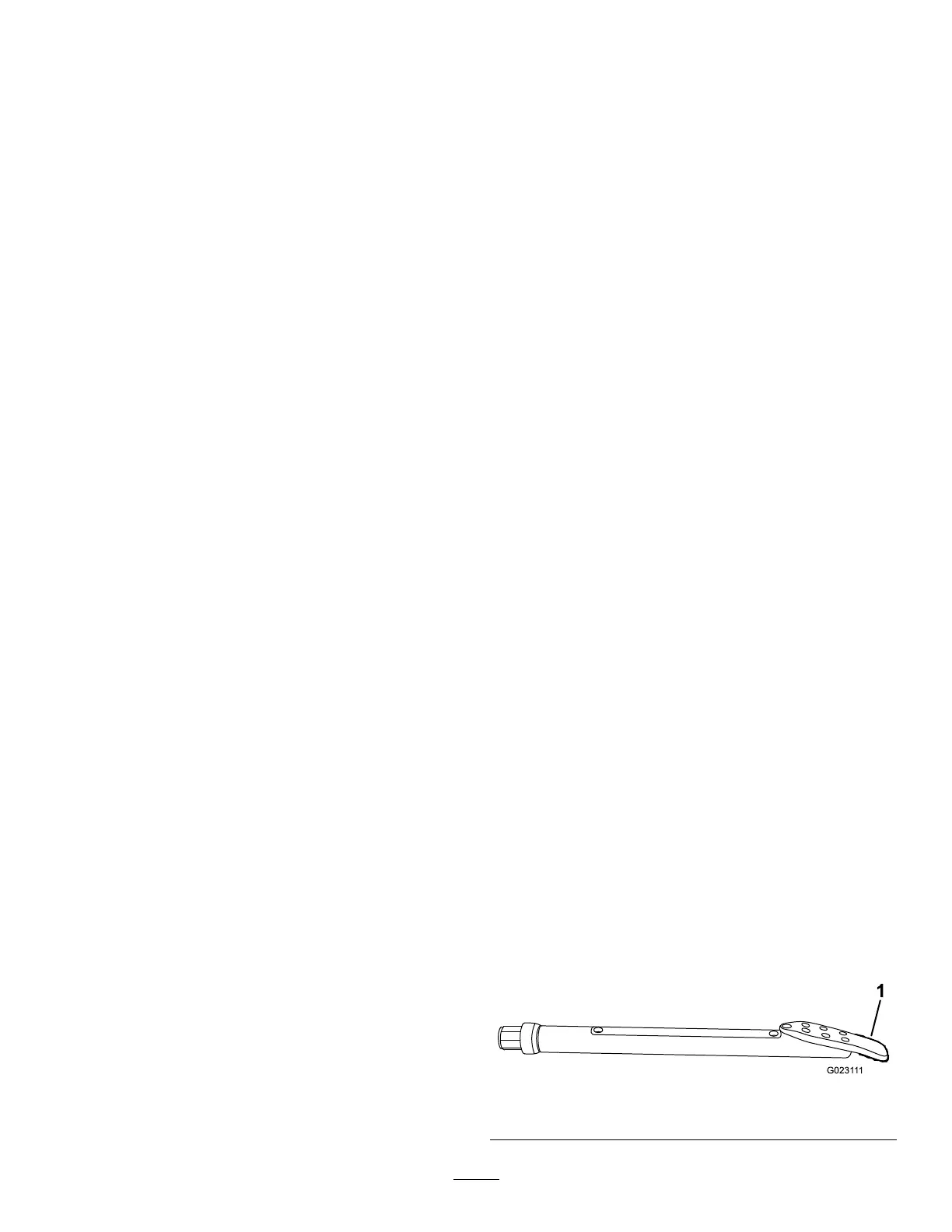

SteeringtheDrillHead

Thedrillbitisshapedlikeawedge,angledfromonesideof

thebittotheother.Whenyoupushthebitthroughthesoil

withoutrotatingit,itwillveertowardthedirectionthewedge

ispointing.Whenyourotatethepipeanddrillheaditbores

throughthesoilinastraightpath.

Figure52

1.Drillbit

51

Loading...

Loading...