10

5

Step

Parts needed for this step:

• 1 Pulley assembly

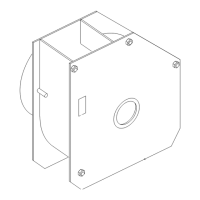

Installing the Pulley Assembly

1. Loosen, but do not remove, the tapping bolts on the

existing pulley (Fig. 9). There should be a 1/4 inch

(0.64 cm) clearance between the bolt head and pulley.

m–7004

4

1

1/4 inch

2

3

(0.64 cm)

Figure 9

1. Pulley assembly, bagger

belt

2. Pulley assembly, drive belt

3. Locking slots

4. Bolts heads

2. Align the new pulley assembly so that the openings fit

over the pulley bolt heads loosened in step 1 and

install (Fig. 9).

3. Turn the pulley to lock it into position (Fig. 9).

Note: If the pulley does not turn, loosen the bolts to raise

the bolt heads and allow the pulley to lock into position.

4. After the new pulley assembly is in position, tighten

the existing bolts to secure new pulley.

Important Torque the nuts to 23 ft-lb ± 2 ft-lb

(31 N⋅m ± 3 N⋅m).

6

Step

No parts needed for this step.

Removing the Drive Wheels

and Bumper Guard

Danger

Mechanical or hydraulic jacks may fail to support

machine and cause a serious injury.

• Use jack stands when supporting machine.

• Do not use hydraulic jacks.

m–6794

1

2

3

Figure 10

1. Rear bumper guard

2. Bolt

3. Nut

1. Remove the existing rear bumper guard (Fig.10.

2. Loosen the drive wheel lugs or nuts.

3. Raise the rear of the machine and support with jack

stands.

4. Remove the drive wheels.

Loading...

Loading...