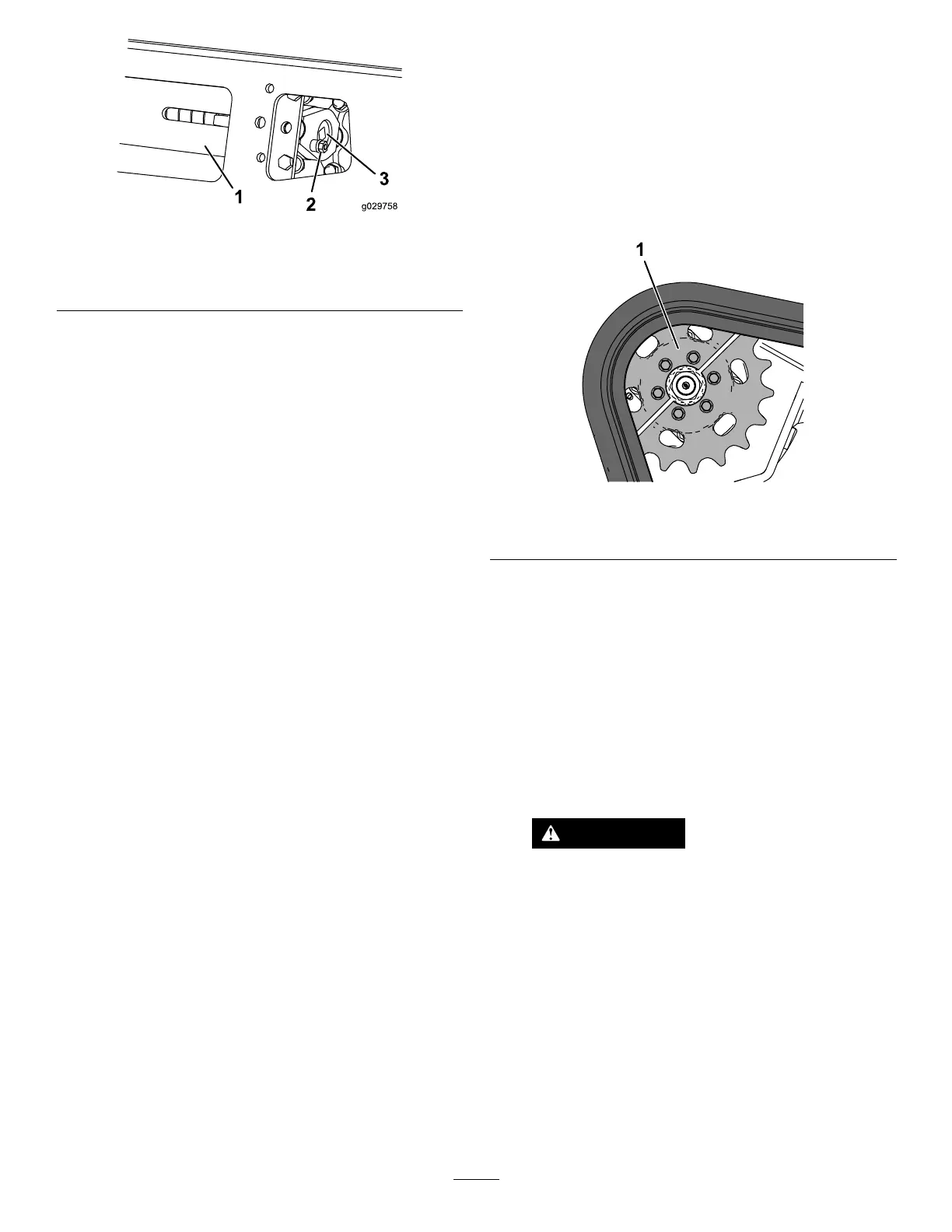

g029758

Figure59

1.Tensiontube3.Tensioningscrew

2.Lockingbolt

4.Usinga1/2inchdriveratchet,turnthetensioning

screwuntilthetensionblockalignswiththe

greenguideonthedecaloris1.3cm(1/2inch)

awayfromtherearofthetensiontubeslot

(Figure58).

Note:Turningthescrewcounter-clockwise

tightensthetrack;turningthescrewclockwise

loosensthetrack.

5.Aligntheclosestnotchinthetensionscrewto

thelocking-boltholeandsecurethescrewwith

thelockingboltandnut(Figure59).

6.Repeattheprocedurefortheothertrack.

7.Drivethemachine,thenparkthemachineona

levelsurface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

8.Verifythatthetensionblockalignswiththe

greenguideofthedecaloris1.3cm(1/2inch)

awayfromtherearofthetensiontubeforboth

tracks(Figure58).Adjustifnecessary.

ReplacingtheTracks

MachineswithNarrow-WidthTracks

Replacethetrackswhentheyarebadlyworn.

1.Removeanyattachments.

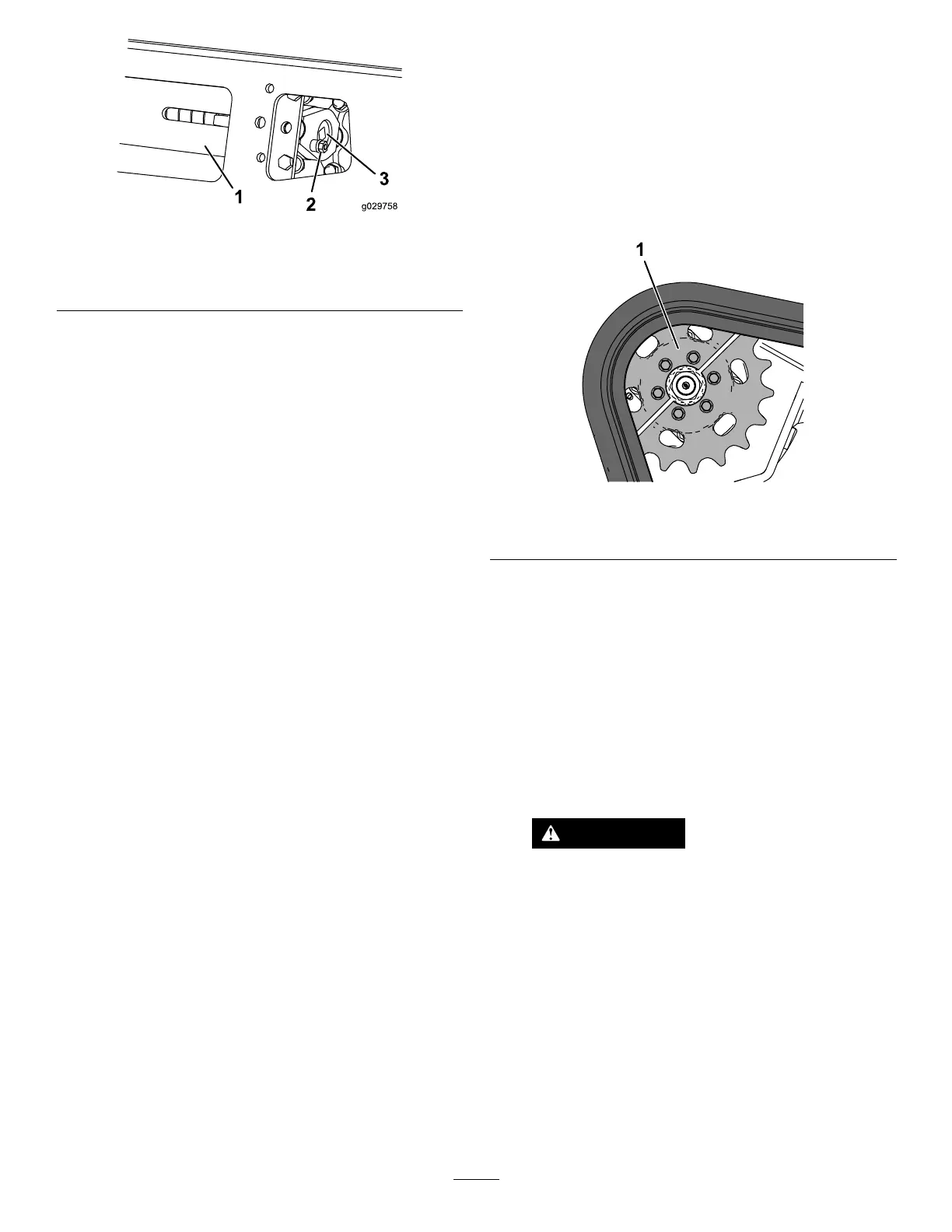

2.Parkthemachineonalevelsurface,ensuring

thatonly1sprockethalfisengagedwiththe

track(Figure60).

g259714

Figure60

1.Sprockethalf

3.Engagetheparkingbrake.

4.Lowertheloaderarmssothattheyare

approximately20to25cm(8to10inches)

abovetheframe.

5.Shutofftheengineandremovethekey.

6.Raisethemachineoffthegrounduntilyou

canaccesstheinsideofthetrackbeneath

themachine.Supportthemachineusingjack

stands.

Note:Usejackstandsratedforyourmachine.

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

7.Removethelockingbolt,spacer,andnut(Figure

57).

8.Usinga1/2-inchdriveratchet,releasethe

drivetensionbyturningthetensioningscrew

clockwise(Figure57andFigure61).

40

Loading...

Loading...