Maintenance

Note:Downloadacopyoftheelectricalschematicbyvisitingwww.T oro.comandsearchyourmachinefrom

theManualslink.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

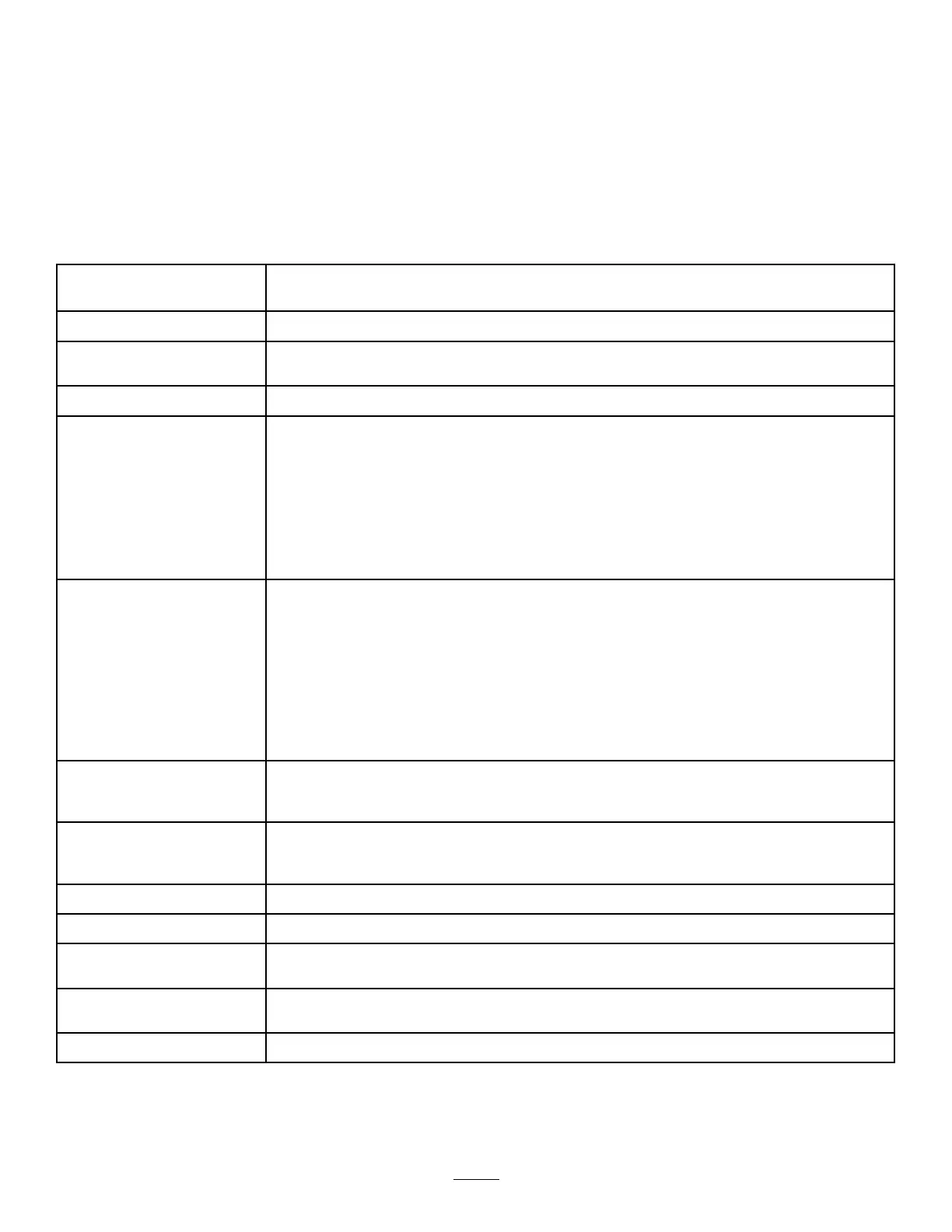

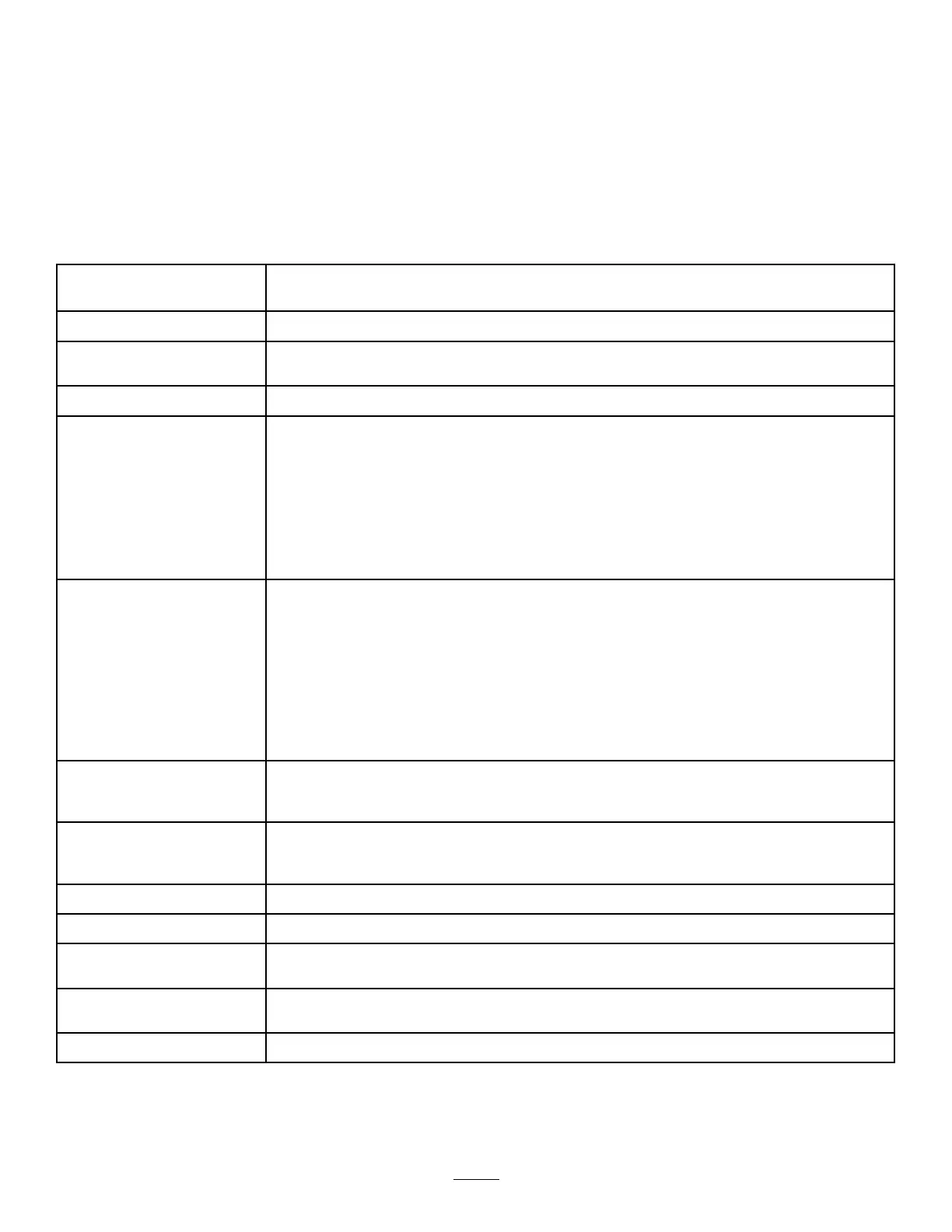

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Checktheconditionofthedrivebelt.

Aftertherst50hours

•Changetheengineoil.

•Changetheengine-oillter.

Aftertherst100hours

•Performthebreakinginanewmachineguidelines.

Beforeeachuseordaily

•Preformthepre-staringchecks.Checkthefollowingitemseachtimeyoubegin

usingthemachinefortheday:

•Checkthebrake-uidlevel.

•Checktheengineoil.Checktheoillevelintheenginebeforetheengineisrst

started.

•Checkthetirepressure.

•Checkgear-shiftoperation.

•Inspecttheprimary-driveclutch.

•Checktheradiator-coolantlevel.

Every100hours

•Greasethebearingsandbushings.

•Replacetheairlter.Replacetheair-lterelementsoonerifitdirtyordamaged.

•Checktheconditionofthetiresandrims.

•T orquethewheel-lugnuts.

•Inspectthesteeringandsuspensionforlooseordamagedcomponents.

•Checkthefrontwheeltoe-inandcamber.

•Checkthetransaxle-uidlevel.

•ChecktheoperationoftheNeutralgear-shiftposition.

•Cleantheengine-coolingareas.

•Inspectthebrakes.

Every150hours

•Changetheengineoil(twiceasofteninspecialoperatingconditions;referto.

•Changetheengine-oillter.Changetheoiltwiceasoftenduringspecialoperating

conditions.

Every200hours

•Cleantheprimary-driveclutch(moreoftenindustyordirtyconditions).

•Adjusttheparkingbrakeifneeded.

•Checktheconditionandtensionofthedrivebelt.

Every300hours

•Greasethefrontwheelbearings.

Every400hours

•Inspectthefuellinesandconnections.

Every800hours

•Replacethefuellter.

•Changethetransaxleuid.

Every1,000hours

•Changetheradiatorcoolant.

•Changethebrakeuid.

Yearly

•Completeallyearlymaintenanceproceduresspeciedintheengineowner'smanual.

27

Loading...

Loading...