FuelSystem

Maintenance

InspectingFuelLinesand

Connections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellines,ttings,andclampsforsignsof

leaking,deterioration,damage,orlooseconnections.

Note:Repairanydamagedorleakingfuelsystem

componentbeforeusingthemachine.

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

1.Raisetheboxandsupportitwiththeproprod.

2.Placeacleancontainerunderthefuellter.

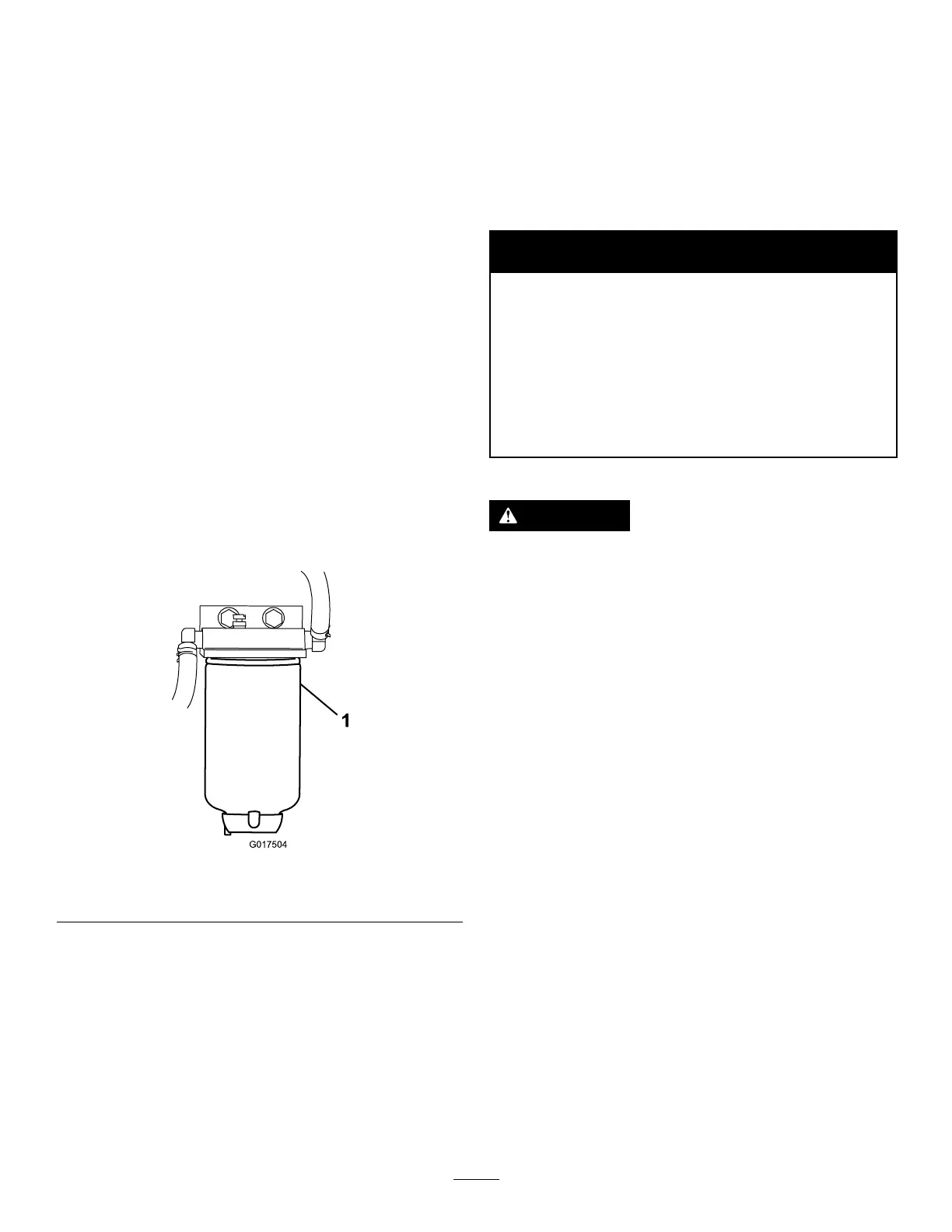

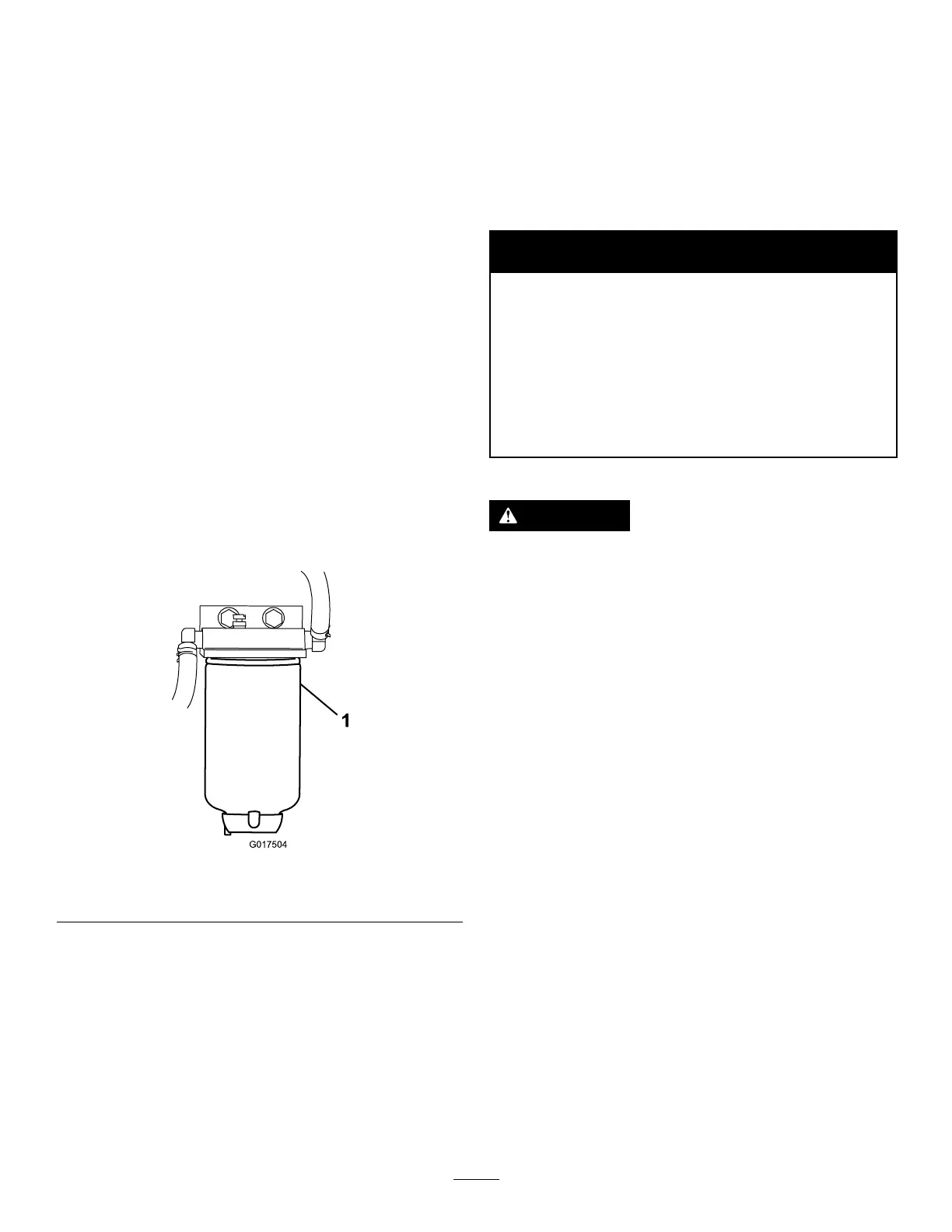

3.Unscrewthefuellterfromthebracket(Figure

39).

g017504

Figure39

1.Fuellter

4.Installthereplacementlterbyturningituntilthe

ltercontactsthetopofthebracket,thentighten

itanadditional3/4ofaturn.

ElectricalSystem

Maintenance

ServicingtheBattery

Batteryvoltage:12Vwith300A(coldcranking)at

-18°C(0°F).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacid

whichisfatalifconsumedandcausessevere

burns.

•Donotdrinkelectrolyteorallowitto

contactyourskin,eyesorclothing.Wear

safetyglassestoshieldyoureyesand

rubberglovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

•Alwayskeepthebatterycleanandfullycharged.

•Alwayskeepthebatterycleanandfullycharged.

•Ifthebatteryterminalsarecorroded,cleanthem

withasolutionof4partswaterand1partbaking

soda.

•Applyalightcoatingofgreasetothebattery

terminalstopreventcorrosion.

37

Loading...

Loading...