MS-SVN084A-EN

13

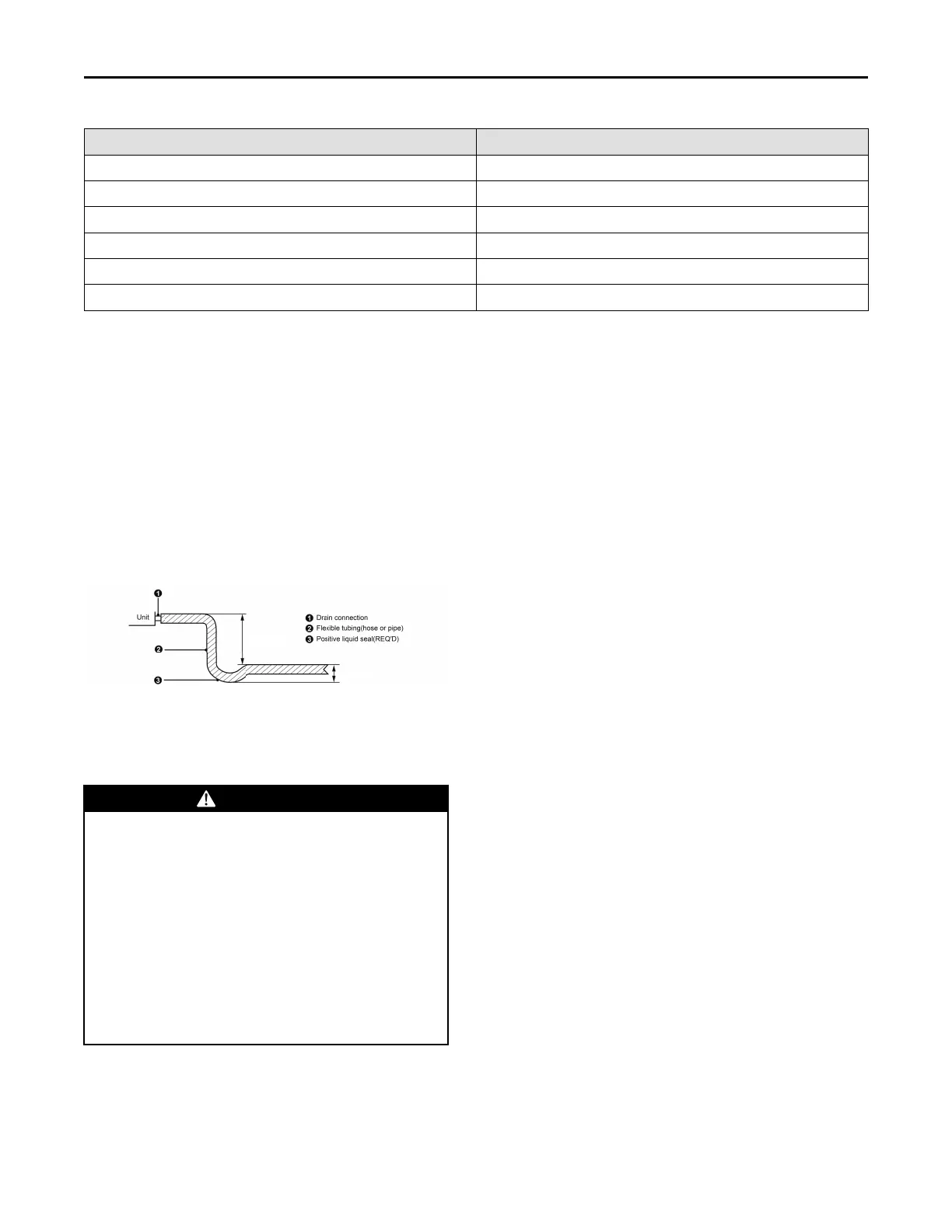

Pipe Diameter inch (mm) Tightening Torque ft-lb (N-m)

Φ1/4 (6.35) 11.06 - 22.13 (15 - 30)

Φ3/8 (9.53) 25.82 - 29.5 (35 - 40)

Φ1/2 (12.7) 33.19 - 36.88 (45 - 50)

Φ5/8 (15.88) 44.25 - 47.94 (60 - 65)

Φ3/4 (19.05) 51.63 - 55.32 (70 - 75)

Φ7/8 (22.23) 59 - 62.69 (80 - 85)

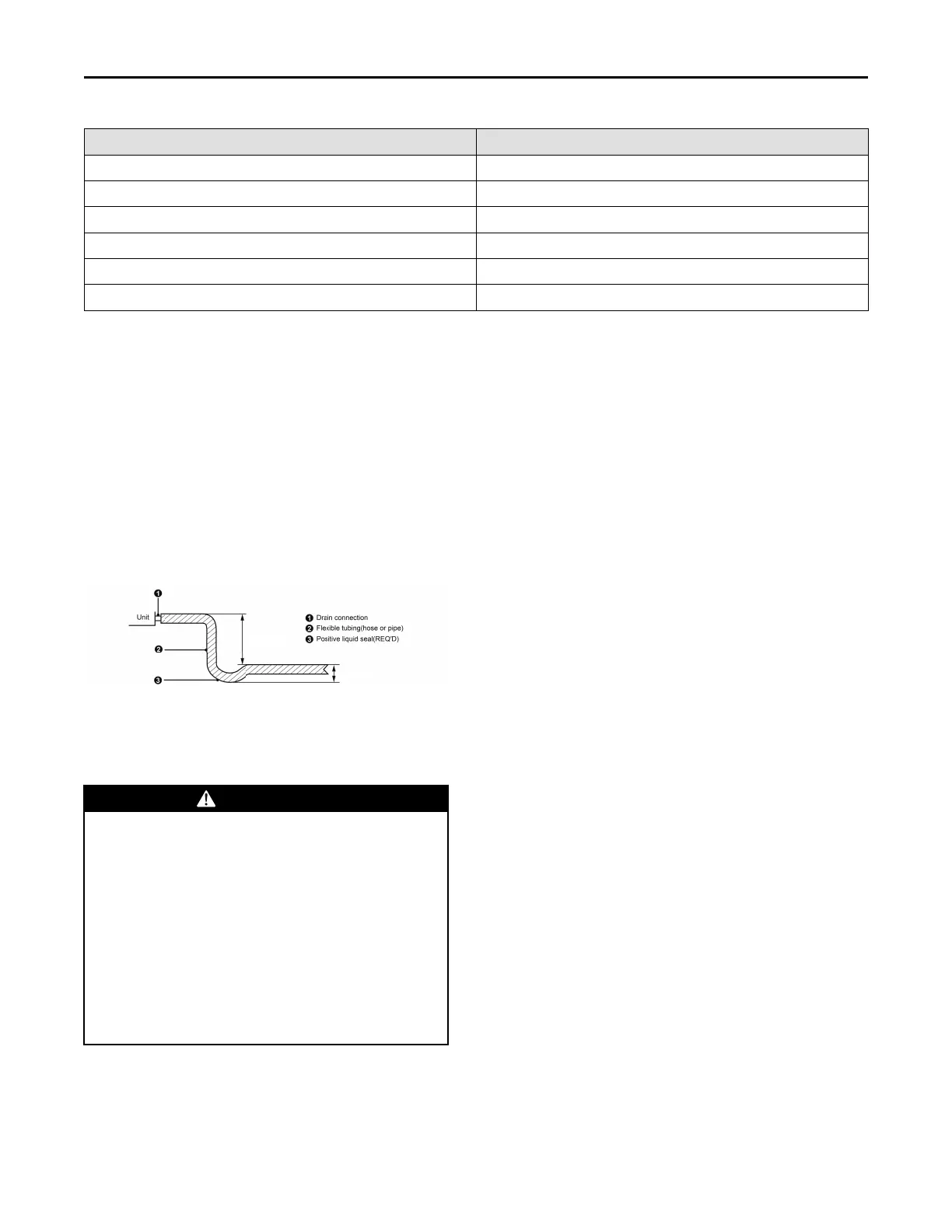

Condensate Removal

1. Condensate drain pipe should be connected into

special drain system for air conditioner.

2. The drain pan has primary and secondary drain

connection. Condensate removal is performed by

attaching a 3/4” PVC pipe to the evaporator coil pan

and terminated in accordance with local or state

Plumbing/HVAC codes. The installation must

include a “P” style trap that is located closely to the

evaporator coil. Do not over-tighten the drain

connection in order to prevent possible damage to

the evaporator drain pan. See the following figure

for details of a typical condensate line “P” trap.

2" (51 mm) minimum

3" (76 mm) minimum

Ductwork

This air handler is designed for a complete supply and

return ductwork system.

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

FFiieelldd dduuccttwwoorrkk mmuusstt mmeeeett tthhee NNaattiioonnaall FFiirree

PPrrootteeccttiioonn AAssssoocciiaattiioonn NNFFPPAA 9900AA,, NNFFPPAA 9900BB aanndd

aannyy aapppplliiccaabbllee llooccaall oorrddiinnaannccee.. SShheeeett mmeettaall

dduuccttwwoorrkk rruunn iinn uunnccoonnddiittiioonneedd ssppaacceess mmuusstt bbee

iinnssuullaatteedd aanndd ccoovveerreedd wwiitthh aa vvaappoorr bbaarrrriieerr..

FFiibbrroouuss dduuccttwwoorrkk mmaayy bbee uusseedd iiff ccoonnssttrruucctteedd aanndd

iinnssttaalllleedd iinn aaccccoorrddaannccee wwiitthh SSMMAACCNNAA

CCoonnssttrruuccttiioonn SSttaannddaarrdd oonn FFiibbrroouuss GGllaassss DDuuccttss..

DDuuccttwwoorrkk mmuusstt ccoommppllyy wwiitthh NNaattiioonnaall FFiirree

PPrrootteeccttiioonn AAssssoocciiaattiioonn aass tteesstteedd bbyy UU//LL SSttaannddaarrdd

118811 ffoorr CCllaassss II AAiirr DDuuccttss.. CChheecckk llooccaall ccooddeess ffoorr

rreeqquuiirreemmeennttss oonn dduuccttwwoorrkk aanndd iinnssuullaattiioonn..

• Duct system must be designed within the range of

external static pressure the unit is designed to

operate against. It is important that the system

airflow be adequate. Make sure supply and return

ductwork, grills, special filters, accessories, etc. are

accounted for in total resistance. See fan

performance data in this manual.

• Do not operate the unit without all ductwork

completed.

• Do not operate this product without all ductwork

attached.

• Inadequate ductwork that restricts airflow can result

in improper performance and compressor or heater

failure. Ductwork is to be constructed in a manner

that limits restrictions and maintains suitable air

velocity. Ductwork is to be sealed to the unit in a

manner that will prevent leakage.

• RReettuurrnn dduuccttwwoorrkk:: Do not terminate the return

ductwork in an area that can introduce toxic or

objectionable fumes/odors into the ductwork. The

return ductwork is to be introduced into the air

handler bottom (up flow configuration).

• RReettuurrnn AAiirr FFiilltteerrss:: Each installation must include a

return air filter. This filtering may be performed at

the air handler or externally such as a return air

filter grille.

Electrical Installation

RReeqquuiirreemmeenntt aanndd NNoottiiccee oonn EElleeccttrriiccaall IInnssttaallllaattiioonn

The electrical installation for the air handler should

observe the following requirements:

1. The electrical installation must be conducted by

trained personnel and done according to the

National Electric Code in addition to local rules and

regulations. The electric circuit must be equipped

with a circuit breaker with sufficient capacity.

2. The unit’s operating power must be within the

nominal range stated in the installation manual.

Use a dedicated power circuit for the air handler. Do

not draw power from another power circuit.

3. The air handler circuit should be at least 5 feet (1.5

m) away from any flammable surface.

4. Connect wiring by referring to the circuit diagram

labeled on the unit and securely tighten.

IInnssttaallllaattiioonn

Loading...

Loading...