AC-SVX003A-EN

59

NOTICE

Evaporator Damage!

Failure to follow these instructions could result in

damage to the evaporator.

If insufficient concentration or no freeze inhibitor is

used, the evaporator water flow must be controlled by

the unit controller AND heaters must be used to avoid

catastrophic damage to the evaporator due to

freezing. It is the responsibility of the installing

contractor and/or the customer to ensure that a pump

will start when called upon by the chiller controls.

Even with water pump control, a power loss of as little

as 15 minutes under freezing conditions can damage

the evaporator. Only the proper addition of freeze

inhibitor or complete drainage of the water circuit can

ensure no evaporator damage in the event of a power

failure.

Low Evaporator Refrigerant

Cutout, Glycol Requirements

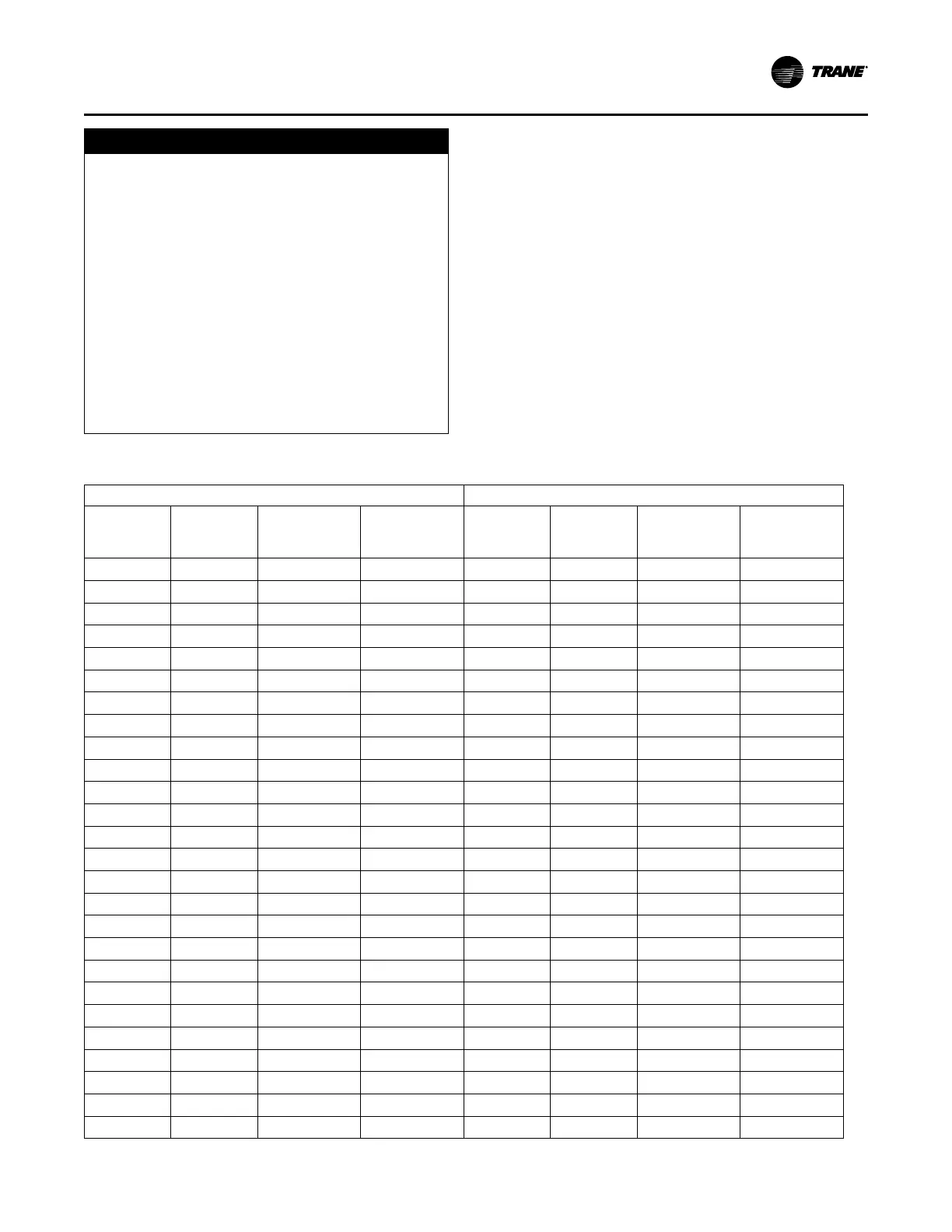

The table below shows the low evaporator temperature

cutout for different glycol levels. Additional glycol beyond

the recommendations will adversely effect unit

performance. The unit efficiency will be reduced and the

saturated evaporator temperature will be reduced. For

some operating conditions this effect can be significant.

additional glycol is used, then use the actual percent glycol

to establish the low refrigerant cutout setpoint.

Note: Tables below are not substitutes for full unit

simulation for proper prediction of unit performance

with specific operating conditions. For information

on specific conditions, contact Trane product

support.

Table 21. Low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout (LWTC) — 150 to

330 ton units

Ethylene Glycol Propylene Glycol

Glycol

Percentage (%)

Solution

Freeze Point (°

F)

Minimum

Recommended

LERTC (°F)

Minimum

Recommended

LWTC (°F)

Glycol

Percentage (%)

Solution

Freeze Point (°

F)

Minimum

Recommended

LERTC (°F)

Minimum

Recommended

LWTC (°F)

0 32 28.6 35 0 32 28.6 35

2 31 27.6 34 2 31 27.6 34

4 29.7 26.3 32.7 4 29.9 26.5 32.9

5 29 25.6 32 5 29.3 25.9 32.3

6 28.3 24.9 31.3 6 28.7 25.3 31.7

8 26.9 23.5 29.9 8 27.6 24.2 30.6

10 25.5 22.1 28.5 10 26.4 23 29.4

12 23.9 20.5 26.9 12 25.1 21.7 28.1

14 22.3 18.9 25.3 14 23.8 20.4 26.8

15 21.5 18.1 24.5 15 23.1 19.7 26.1

16 20.6 17.2 23.6 16 22.4 19 25.4

18 18.7 15.3 21.7 18 20.9 17.5 23.9

20 16.8 13.4 19.8 20 19.3 15.9 22.3

22 14.7 11.3 17.7 22 17.6 14.2 20.6

24 12.5 9.1 15.5 24 15.7 12.3 18.7

25 11.4 8 14.4 25 14.8 11.4 17.8

26 10.2 6.8 13.2 26 13.8 10.4 16.8

28 7.7 4.3 10.7 28 11.6 8.2 14.6

30 5.1 1.7 8.1 30 9.3 5.9 12.3

32 2.3 -1.1 5.3 32 6.8 3.4 9.8

34 -0.7 -4.1 5 34 4.1 0.7 7.1

35 -2.3 -5 5 35 2.7 -0.7 5.7

36 -3.9 -5 5 36 1.3 -2.1 5

38 -7.3 -5 5 38 -1.8 -5 5

40 -10.8 -5 5 40 -5.2 -5 5

42 -14.6 -5 5 42 -8.8 -5 5

Installation Mechanical

Loading...

Loading...