68

AC-SVX003A-EN

is controlling the pump), the diagnostic is cleared, the EWP

is re-energized, and normal control resumed.

If evaporator water flow is lost once it had been

established, the EWP relay remains energized and a non-

latching diagnostic is generated. If flow returns, the

diagnostic is cleared and the chiller returns to normal

operation.

In general, when there is either a non-latching or latching

diagnostic, the EWP relay is turned off as though there was

a zero time delay. Exceptions whereby the relay continues

to be energized occur with:

• Low Chilled Water Temperature diagnostic (non-

latching unless also accompanied by an Evap Leaving

Water Temperature Sensor Diagnostic)

OR

• Interrupt Failure —AFDxA diagnostic where x is

either 1 or 2 to indicate which drive is affected), in

which a compressor continues to draw current even

after commanded to have shutdown.

OR

• Loss of Evaporator Water Flow diagnostic (non-

latching) and the unit is in the AUTO mode, after initially

having proven evaporator water flow.

Evaporator Pump Package

When optional evaporator pump package is installed,

Evaporator Pump Control is set to Single Pump Variable

Speed in Tracer® TU. Additional I/Os are required for

Symbio™ 800 to control and monitor the pump VFD.

Symbio 800 monitors the pump speed, fault, and running

status. Two options selectable in Tracer TU are available

for evaporator pump speed control:

• Direct Pump Speed Control (factory default): Uses

Evap Water Pump Speed setpoint configuration from 0

to 100 percent.

• Water Flow Control: Uses Evap Water Flow Rate

setpoint configuration from 50 to 1200 gpm.

For each speed control option, speed or water flow

setpoints are accessible through the AdaptiView™ Display,

Tracer TU, and building automation system.

Note: For the Water Flow Control option, evaporator water

flow measurement must be installed.

Evaporator Flow Measurement

Fluid flow through the chiller evaporator is calculated by

sensing the pressure drop across its heat exchanger. The

heat exchanger pressure drop is determined by measuring

the pressure difference between entering and leaving

pressures in the evaporator water box. Using this sensed

pressure drop, along with coefficients specific to each heat

exchanger, the fluid flow rate through the evaporator is

computed and displayed at the human interface. Once the

flow rate through the evaporator is known, chiller capacity

can be determined. The differential water pressure range is

configurable from 0 to 50 psid.

Three configurable water flow measurement types are

available (selectable in Tracer® TU):

• Differential Pressure (4-20mA input to Trane LLID)

• Flow Meter (4-20mA input to Trane LLID)

• Dual Pressure Sensors (entering and leaving pressure

transducer Trane LLIDs)

Flow calibration points are factory programmed. Contact

technical support for flows and pressure drops used for

flow calibration if Symbio™ 800 required reprogramming in

the field. These setpoints are accessible in Tracer TU.

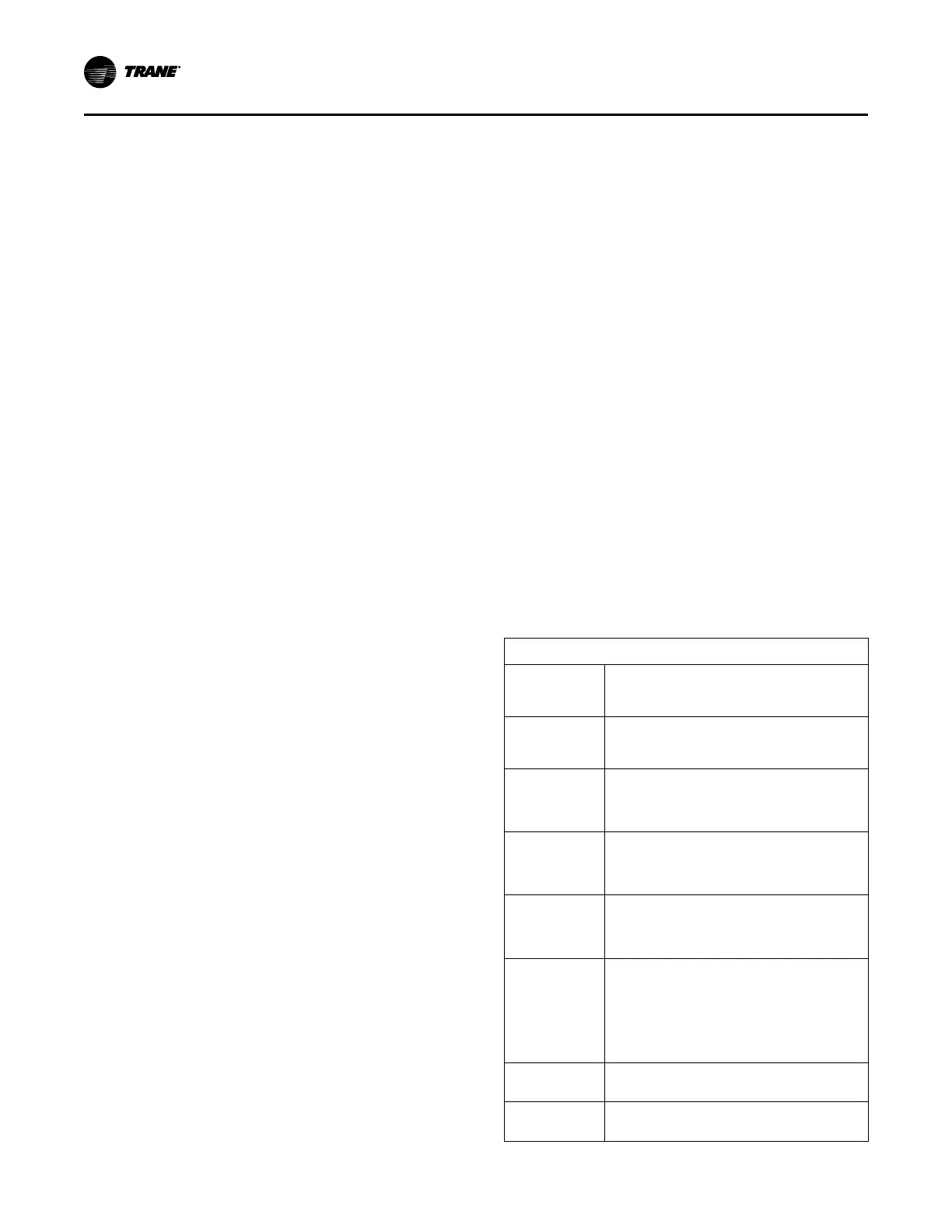

Programmable Relays

An optional programmable four relay LLID provides hard-

wired interlock of certain events or states of the chiller,

selected from a list of likely needs, as shown in the field

wiring diagram. The relay contacts are single-pole-double-

throw (SPDT) and are suitable for use with 120VAC at 7.2A

resistive, 2.88A pilot duty, and 1/3 HP (7.2A) or with

240VAC at 5A general purpose duty.

The list of events/states that can be assigned to the

programmable relays can be found in the following table.

The relay will be energized when the event/state occurs.

Table 25. Alarm and status relay output

configurations

Description

Alarm

(Latching)

This output is true whenever there is any active

latching shutdown diagnostic that targets the Unit,

Circuit, or any of the Compressors on a circuit.

Alarm

(Non-Latching)

This output is true whenever there is any active

non-latching shutdown diagnostic that targets the

Unit, Circuit, or any of the Compressors on a circuit.

Alarm

This output is true whenever there is any active

latching or non-latching shutdown diagnostic that

targets the Unit, Circuit, or any of the Compressors

on a circuit.

Alarm Ckt 1

This output is true whenever there is any active

latching or non-latching shutdown diagnostic that

targets Circuit 1, or any of the Compressors on

Circuit 1.

Alarm Ckt 2

This output is true whenever there is any active

latching or non-latching shutdown diagnostic that

targets Circuit 2, or any of the Compressors on

Circuit 2.

Unit Limit Mode

This output is true whenever a circuit on the unit

has been running in one of the limit modes

continuously for the Limit Relay debounce time. A

given limit or overlapping of different limits must be

in effect continuously for the debounce time prior to

the output becoming true. It will become false if no

limits are present for the debounce time.

Compressor

Running

The output is true whenever any compressor is

running.

Circuit 1

Running

The output is true whenever any compressor of

Circuit 1 is running.

Installation Electrical

Loading...

Loading...